U.S. Bellows customized single-ply X-Flex bellows for the world’s largest manufacturer and supplier of flooring products with locations throughout the U.S. Flooring products such as carpet, ceramic tile, natural stone, laminate, vinyl, and hardwood require many of the same piping systems as traditional indoor plants for the automotive, food processing, semiconductor, textile, and pulp & paper industries. Plants that manufacture flooring are usually quite large requiring large tracks of land. As a result, the “pipe runs” can extend hundreds of feet requiring various types of expansion joints to accommodate the movement of the pipe while also relieving stresses in the piping system. Externally pressurized expansion joints are especially suited for piping systems that require large amounts of axial compression or extension. In externally pressurized pipe expansion joints, the bellows elements are arranged so that the media flow is on the external surface of the bellows. Externally pressurizing the bellows eliminates pressure instability as a limitation to the design and permits the absorption of large amounts of axial expansion. These expansion joints are fabricated with 304 stainless steel bellows, flanges, and pipe. They are designed for 300°F at 14.7 psig with an 8″ extension. The units are 3″ pipe x 40″ long, and 4″ pipe x 40″ long. The expansion joints were hydro-tested and underwent NDE quality control inspection tests such as liquid penetrate inspection (LPI) before shipment.

Read MoreBlog

Super U-Loop Expansion Joint Designed for a Chilled Water Line

Super U-Loop Expansion Joint Designed for a Chilled Water Line for Paint and Body Shops in Automotive Manufacturing Plants

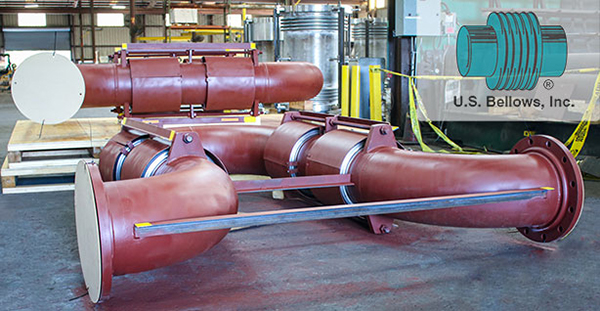

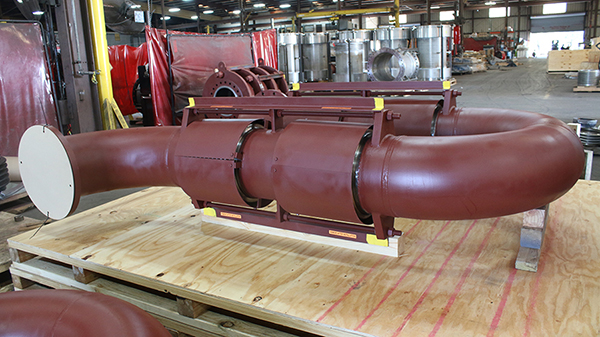

U.S. Bellows, a division of PT&P has developed its Super U-Loop and Super V-Loop product line for applications requiring accommodation of axial growth typically on longer runs of piping. The Super U-Loop and Super V-Loop designs restrain pressure thrust without any anchoring in the piping system. U.S. Bellows is the first company to bring its advanced expansion joint technology used in the world’s most challenging applications to a standard V-Loop and U-Loop product offering. U.S. Bellows expansion joints are used in key process areas in oil and gas, chemical, power, semiconductor, food, automotive, and other operating plants in extreme environments which include temperatures over 1000°F, pressure over 200 PSI, and a wide variety of highly corrosive materials. This particular U-loop shown in the picture below was designed, manufactured, and shipped in less than 9 days from our Houston-based manufacturing facility.

| Option | Super U-Loop Advantages | Super U-Loop Disadvantages |

| Pipe Loop | · Super U-Loop requires far less space

· Can be designed to accommodate large amounts of axial movement |

· Pipe loop is a lower cost if the space is available |

| Flexible Metal Hose Based U-Loop and V-Loop | · Flow liner protects the interior of the bellows

· Cover on Bellows protects exterior of bellow – Flexible metal hose can be damaged easily by accidental bumping, banging, etc. · Super U-Loop can be designed with varying thickness to optimize strength versus lower spring rate · Super U-Loop can be made with custom metals to accommodate environmental conditions – includes Hastelloy, Inconel, Monel, … · Designed to better withstand vibration in Piping System · Standard designs can be delivered in as little as 1 week |

· Flexible metal hose offers a very low spring rate |

U.S. Bellows/PT&P’s Super U-Loop and Super V-Loop offer a breakthrough option for accommodating large amounts of axial growth in both commercial and high-temperature industrial environments. The traditional option used when space was not available for a pipe loop was a flexible metal hose which introduced the risk of failure into the piping system. U.S. Bellows design is built around minimizing the risk of failure by:

- Flow Liner – protects the interior of the Bellows

- Cover – protects the exterior of the Bellows for damage such as falling wrenches, accidental banging by a forklift, etc.

- Limits Excessive Cycling – if vibration in the piping system “cycles”, a flexible metal hose may not be an adequate solution. The reason is that neither expansion joints nor flexible metal hoses are designed to support millions of cycles. The low spring rate of the flexible metal hose makes it more vulnerable to being cycled by unintended continuous vibration in the piping system. Even 1 Hz of vibration rapidly leads to excessive cycling with 86,400 cycles per day. By incorporating either a Super U-Loop or Super V-Loop with an expansion joint, we are able to accommodate a large amount of movement with the ability to dampen vibration due to the higher spring rate of the expansion joint design.