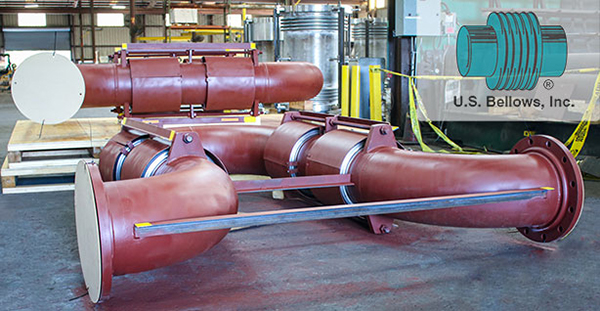

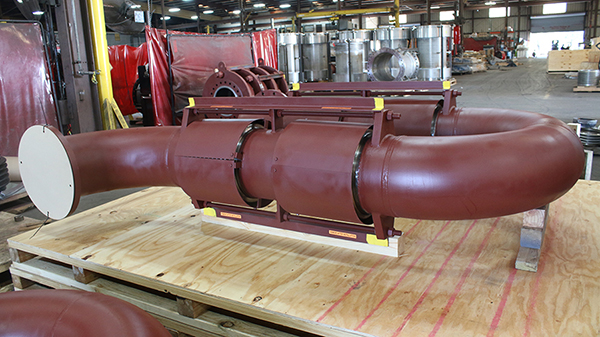

Super U-Loop Expansion Joint Designed for a Chilled Water Line for Paint and Body Shops in Automotive Manufacturing Plants

| Option | Super U-Loop Advantages | Super U-Loop Disadvantages |

| Pipe Loop | · Super U-Loop requires far less space

· Can be designed to accommodate large amounts of axial movement |

· Pipe loop is a lower cost if the space is available |

| Flexible Metal Hose-Based U-Loop and V-Loop | · Flow liner protects the interior of the bellows

· Cover on Bellows protects the exterior of the bellow – Flexible metal hose can be damaged easily by accidental bumping, banging, etc. · Super U-loop can be designed with varying thickness to optimize strength versus a lower spring rate · Super U-loop can be made with custom metals to accommodate environmental conditions – includes Hastelloy, Inconel, Monel, … · Designed to better withstand vibration in the piping system · Standard designs can be delivered in as little as 1 week |

· Flexible metal hose offers a very low spring rate |

U.S. Bellows/PT&P’s Super U-loop and Super V-loop offer a breakthrough option for accommodating large amounts of axial growth in both commercial and high-temperature industrial environments. The traditional option used when space was not available for a pipe loop was a flexible metal hose, which introduced the risk of failure into the piping system. U.S. Bellows design is built around minimizing the risk of failure by:

- Flow Liner – Protects the interior of the bellows

- Cover – Protects the exterior of the bellows from damage such as falling wrenches, accidental banging by a forklift, etc.

- Limits Excessive Cycling – If vibration in the piping system “cycles”, a flexible metal hose may not be an adequate solution. The reason is that neither expansion joints nor flexible metal hoses are designed to support millions of cycles. The low spring rate of the flexible metal hose makes it more vulnerable to being cycled by unintended continuous vibration in the piping system. Even 1 hz of vibration rapidly leads to excessive cycling with 86,400 cycles per day. By incorporating either a Super U-loop or Super V-loop with an expansion joint, we are able to accommodate a large amount of movement with the ability to dampen vibration due to the higher spring rate of the expansion joint design.