|

|||

|

|

||

12″ Expansion Joint:

|

10″ Expansion Joint:

|

||

|

|

||

16″ Expansion Joint:

|

10″ Expansion Joint:

|

||

Blog

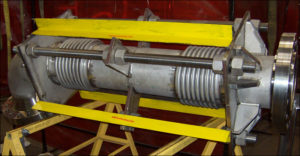

32″ Universal Expansion Joints for an Epoxy Resin Plant

U.S. Bellows, Inc. designed and fabricated a 32″ universal expansion joint and 3″ single expansion joints to be utilized in a new epoxy resin plant in Saudi Arabia. The expansion joints are fabricated with stainless steel bellows and carbon and stainless steel flanges. The 32″ expansion joint has a design temperature of 482°F with a design pressure of 15 PSIG. The 3″ single expansion joints have a design temperature of 400°F with a design pressure of 370 PSIG.

The flanges on the 32″ universal expansion joint were custom fabricated to the customer’s special design requirements. One end of the 32″ expansion joint has a stainless steel custom machined flange with a grooved facing. The other end has a carbon steel lap joint flange. Each expansion joint was 100% dye-penetrant tested as well as hydro-tested.

Read More