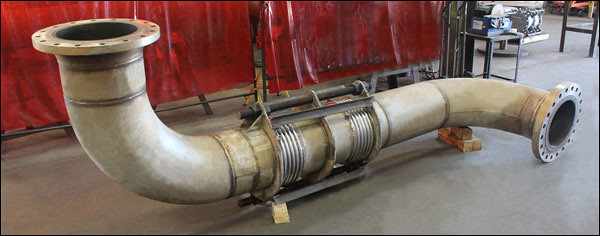

U.S. Bellows custom-designed inline pressure balanced expansion joints for a pipeline in Texas. The bellows are fabricated from 316 stainless steel and the flanges and liners from carbon steel. The units have a 20″ diameter and are 30″ in overall length. The expansion joints were designed for 0.17″ compression with an operating temperature of 150°F at 285 psig. A dye penetrant test and pressure test at 300 PSIG was performed prior to shipment.

Read More