What are High-Temperature Expansion Joints?

Expansion joints for high-temperature applications are engineered to accommodate significant thermal expansion, contraction, and vibration in systems operating at temperatures often exceeding 750°F.

Their crucial role lies in accommodating the thermal expansion that pipes experience when transporting high-temperature media, thereby preventing high stresses, bent pipes, cracks, and failures.

Why are Standard Expansion Joints Insufficient for High-Temperature Applications?

Standard expansion joints are manufactured with stainless steel alloys that may rapidly degrade when exposed to continuous high temperatures or rubber, which would melt at high temperatures.

These materials lose their elasticity and become brittle, leading to premature failure.

High temperatures could also exacerbate other issues in expansion joints, such as:

- Deformation (Creep): Materials deform permanently under sustained stress at high temperatures.

- Oxidation & Corrosion: Chemical reactions accelerate, leading to material degradation.

- Thermal Fatigue: Thermal cycles cause weakening and cracking.

High-temperature expansion joints, essential in many industrial applications, rely on Refractory‑lined expansion joints and insulation materials to form a protective liner cover that resists extreme heat and prevents thermal stress.

Temperature Ratings and Applications of Expansion Joint Materials

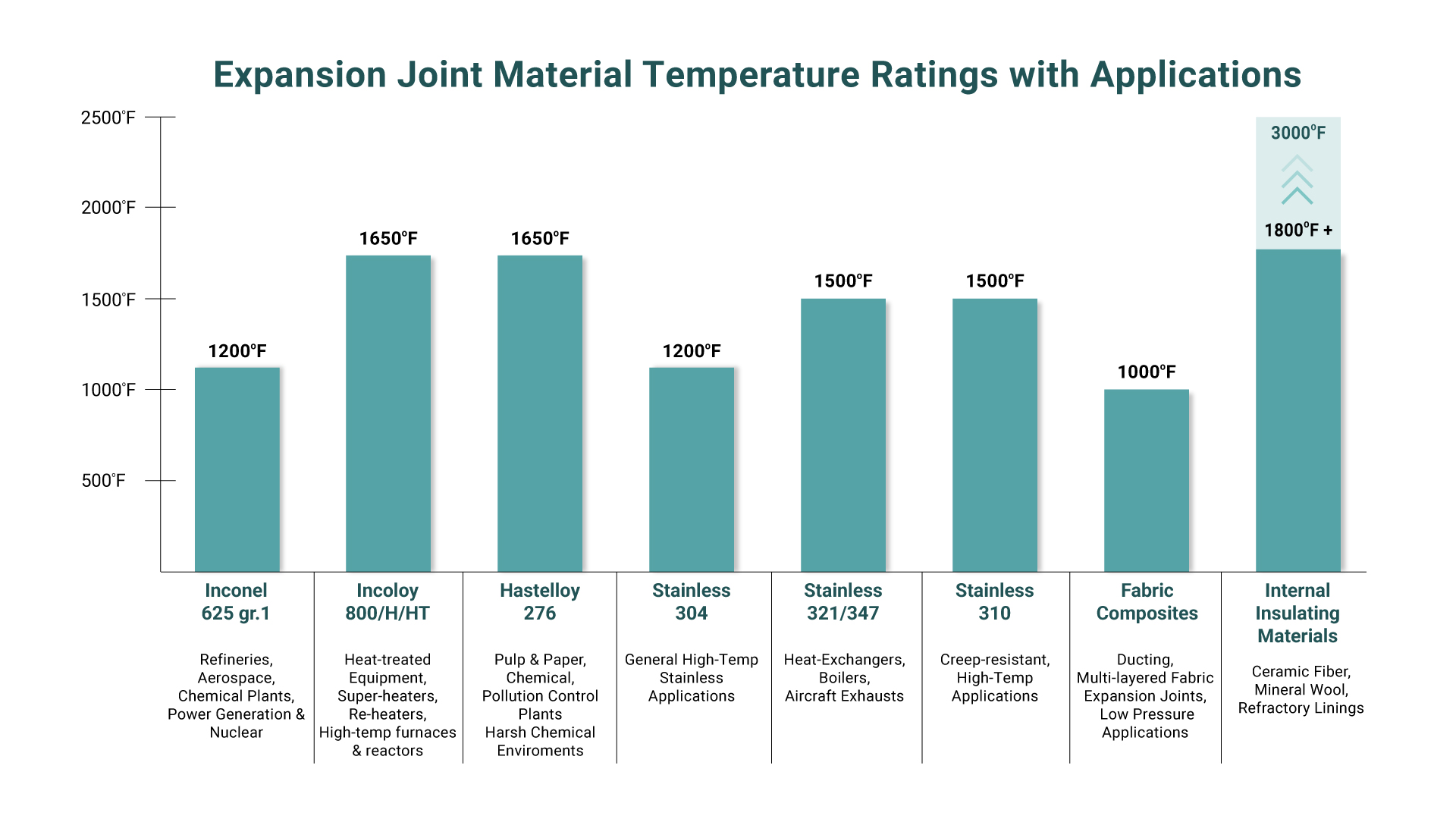

Expansion joints for high-temperature environments are designed using a range of specialized materials, each chosen for its ability to withstand heat, maintain mechanical strength, and resist oxidation, creep, and corrosion.

The chart below illustrates the maximum temperature ratings of commonly used materials, including high-nickel alloys (Inconel 625, Incoloy 800/H/HT, and Hastelloy 276), specialized stainless steels (304, 321/347, and 310), fabric composites, and internal insulating materials, along with their typical applications.

From refineries, aerospace, and chemical plants to ducting systems, boilers, and pollution control facilities, the chart provides a clear comparison of where each material is most effective.

Notably, for environments exceeding 1800°F, internal insulating materials such as ceramic fibers, mineral wool, and refractory linings are recommended to protect components. Temperature ratings indicated are without added insulation.

Why Choose US Bellows for Your High-Temperature Expansion Joints?

US Bellows stands as a leader in designing and manufacturing custom-engineered solutions that meet the most stringent industrial demands. With decades of experience, cutting-edge technology, and a commitment to quality, our team delivers durable, high-performance expansion joints that ensure the safety of your high-temperature systems.

Most of our expansion joints manufactured for high-temperature piping systems, can be designed, manufactured, and out the door within eight weeks.

Investing in the right materials, design, and maintenance practices for these specialized joints can significantly extend the lifespan of your valuable infrastructure.

Contact Our Experts: Do you need a high-temperature expansion joint solution tailored to your extreme conditions? Connect with our engineering team today for a personalized consultation.

OR

Get a Quote: Request a detailed quote to optimize your high-temperature operations with our durable expansion joints.

Read More