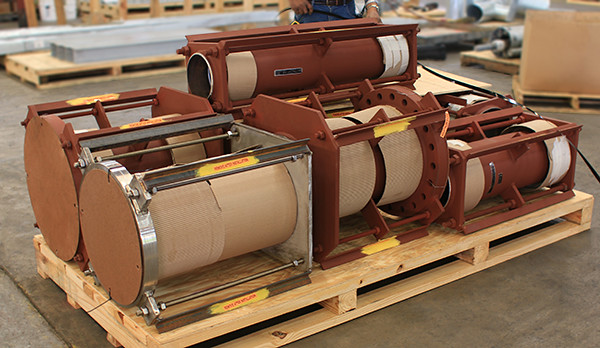

Universal expansion joints such as these are used in chemical plants that manufacture petrochemicals (such as ethylene and styrene monomer), polymers, and building products (PVC profiles for windows, doors, and decking). The units range from 26” to 48” in length and 8” to 20” in diameter. The bellows were fabricated from 321 stainless steel, the weld ends, pipe spools, and flanges from 304 stainless steel, and the tie rods and hex nuts from carbon steel. They are designed for temperatures ranging from -150°F to 800°F, operating pressures ranging from 50 to 240 psig, and 0.25” to 2.25” of lateral deflection. The expansion joints were air, soap, and bubble tested, 100% dye-penetrant tested and hydro-tested before shipment. The universal pipe expansion joint consists of two bellows separated by a pipe section or spool. The primary purpose of this arrangement is to have a unit that will accept large amounts of lateral deflection. The amount of lateral deflection they can accept is a function of the amount of angulation each bellows can absorb and the distance between the bellows. For a given bellows element, the amount of lateral deflection capability can be increased or decreased by simply changing the length of the center spool.

Read More

US Bellows is a Standards Subscriber | Exp: Dec 31, 2026 | See ejma.org to check verification process

Celebrating over 20 years of EJMA membership