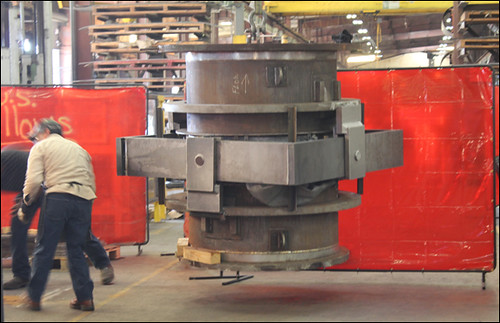

This 28″ diameter by 43″ OAL single gimbal expansion joint with a square gimbal box was designed by U.S. Bellows for a pipeline in Tennessee. The bellows are fabricated from Inconel® 625 LCF and the pipe and liners from 316 stainless steel. The expansion joint is designed for an operating temperature of 1250°F at 120 psig. The assembly has a floating ring gimbal design that restrains the pressure thrust. The unit was dye penetrant examined, all welds were 100% X-rayed, PMI, and hydro-tested prior to shipment.

Blog

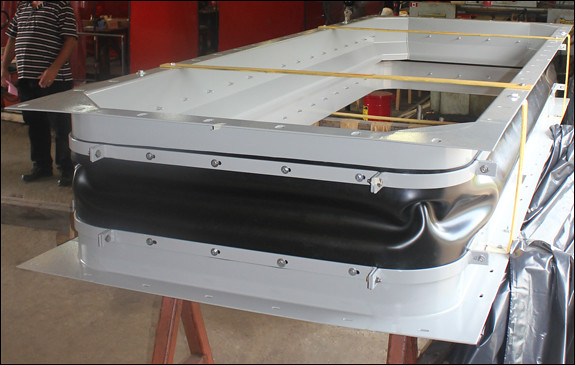

153″ Fabric Expansion Joint for a Gas Turbine Facility

U.S. Bellows designed this fabric expansion joint for a gas turbine application. The dimensions for the expansion joint are 153” x 55” x 21”. The fabric belt is made from reinforced neoprene, while the frame and liner are fabricated from A572 Gr.50 carbon steel. The expansion joint is designed for -20°F/+200°F at +/- 100″ water column. A 100% dye-penetrant examination on the welds was preformed prior to shipment.

136″ Dia. Universal Expansion Joint for a Thermal Power Plant

U.S. Bellows designed this universal expansion joint for a thermal power plant in Oregon. The expansion joint is 136″ in diameter and 36″ in OAL. The bellows are fabricated from stainless steel and the flanges and pipe are carbon steel. It is designed for a lateral movement of 1/2″ at 250°F and 15 psig. The expansion joint was 100% dye-penetrant tested prior to shipment.