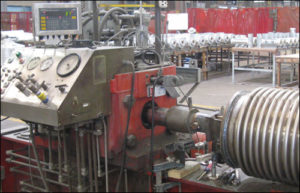

A burst test is performed under controlled conditions and pressure is applied over a period of one to two hours using the necessary safety precautions for all personnel involved.

A burst test is performed under controlled conditions and pressure is applied over a period of one to two hours using the necessary safety precautions for all personnel involved.

A burst test is performed under controlled conditions and pressure is applied over a period of one to two hours using the necessary safety precautions for all personnel involved.

Blotting on a dye-penetrant test typically indicates a crack in the weld. Therefore, the crack would be repaired and the test performed once again.

Blotting on a dye-penetrant test typically indicates a crack in the weld. Therefore, the crack would be repaired and the test performed once again.

The bellows is placed on a test machine and allowed to cycle continually until the bellows fail.

| Fabric Expansion Joints can withstand up to 3 PSIG (pounds per square inch gauge) or 100″ of water (H₂O) column (In pressure). If the pressure exceeds this amount, it is best to use a metallic expansion joint. |

| Fabric Expansion Joints can withstand up to 3 PSIG (pounds per square inch gauge) or 100″ of water (H₂O) column (In pressure). If the pressure exceeds this amount, it is best to use a metallic expansion joint. |

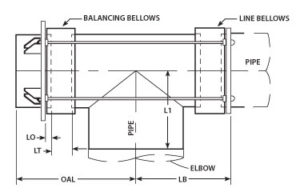

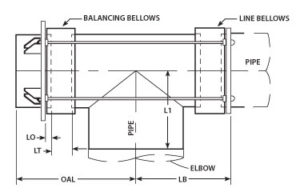

The pressure is equal on both sides for a pressure balanced expansion joint. If the pressure difference is minor, it would not be a problem, but if the pressure thrust is high, then an imbalance of forces would occur and could result in forces being transmitted to adjacent equipment.

The pressure is equal on both sides for a pressure balanced expansion joint. If the pressure difference is minor, it would not be a problem, but if the pressure thrust is high, then an imbalance of forces would occur and could result in forces being transmitted to adjacent equipment.

We recommend that the bellows be tested to 1.5 times the design pressure.

The pressure rating is the maximum allowable pressure that the particular expansion joint can absorb. This is determined on a case-by-case basis.

The pressure rating is the maximum allowable pressure that the particular expansion joint can absorb. This is determined on a case-by-case basis.

Pressure balance joints balance the pressure thrust forces inside of the expansion joint tie rods.

Pressure balance joints balance the pressure thrust forces inside of the expansion joint tie rods.

In an axial piping system, the expansion joint should be located as close as possible to a main anchor. The first pipe guide should be located at a distance of 4 pipe diameters away from the expansion joint. The second guide should be located a distance of 14 pipe diameters away from the first guide. During installation, the expansion joint should be either welded or flanged into the piping system.

In an axial piping system, the expansion joint should be located as close as possible to a main anchor. The first pipe guide should be located at a distance of 4 pipe diameters away from the expansion joint. The second guide should be located a distance of 14 pipe diameters away from the first guide. During installation, the expansion joint should be either welded or flanged into the piping system.

Yes, if they are testing just the expansion joint or if they are testing when installed, they have to make sure that the pipe line is anchored or have limit rods added to the expansion joint to absorb the pressure thrust.

Yes, if they are testing just the expansion joint or if they are testing when installed, they have to make sure that the pipe line is anchored or have limit rods added to the expansion joint to absorb the pressure thrust.

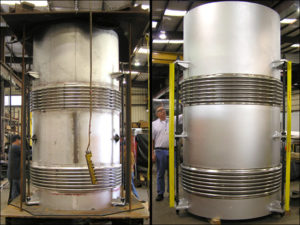

The pressure rating an expansion joint can take depends upon pipe size and temperature. Standard units from 3 inches to 24 inches are suitable for 300 PSIG. (pounds per square inch) Higher pressures can be accommodated on a case by case basis.

The pressure rating an expansion joint can take depends upon pipe size and temperature. Standard units from 3 inches to 24 inches are suitable for 300 PSIG. (pounds per square inch) Higher pressures can be accommodated on a case by case basis.

If the expansion joint is not tied the pressure thrust will act on the turbine exhaust nozzle and the adjacent piping.

If the expansion joint is not tied the pressure thrust will act on the turbine exhaust nozzle and the adjacent piping.

The pressure rating is the maximum allowable pressure to be used for that particular expansion joint. Each pressure rating is specified on a case-by-case basis per expansion joint.

The pressure rating is the maximum allowable pressure to be used for that particular expansion joint. Each pressure rating is specified on a case-by-case basis per expansion joint.

It is the force generated due to the pressure inside the expansion joint. Pressure thrust is calculated by multiplying the area of the mean bellows diameter by the pressure.

Squirm pressure is the pressure at which in-plane instability occurs.

Squirm pressure is the pressure at which in-plane instability occurs.

Hydro-test pressure & holding times vary for different design codes. For example, the ASME SEC VIII Div.1 general hydro-test pressure will be 1.3 x design pressure (minor factors may vary for this equation as well) and for piping design codes, the hydro-test pressure will be ASME B31.4,B31.8 1.5 x design pressure.

Hydro-test pressure & holding times vary for different design codes. For example, the ASME SEC VIII Div.1 general hydro-test pressure will be 1.3 x design pressure (minor factors may vary for this equation as well) and for piping design codes, the hydro-test pressure will be ASME B31.4,B31.8 1.5 x design pressure.

| Pressure thrust load is calculated by finding the area of the mean diameter of the bellows and multiplying it by the design pressure. |

| Pressure thrust load is calculated by finding the area of the mean diameter of the bellows and multiplying it by the design pressure. |

Expansion joints failure is caused by corrosion, erosion, cyclic fatigue or thermal creep at elevated temperatures.

Rubber bellows can crack if they are over-pressurized or placed in a harsh environment.

Rubber bellows can crack if they are over-pressurized or placed in a harsh environment.

Failures can occur for many reasons, but experience has shown that certain causes of failure fall into fairly distinct categories.

Shipping and handling damage. Examples: Denting or gouging of bellows from being struck by hard objects (tools, chain falls, forklifts, adjacent structures, etc.); improper stacking for shipping or storage; insufficient protection from weather or other adverse environmental conditions.

Improper installation and insufficient protection.

During and after installation.

Examples: Joints with internal liners installed in the reverse direction with respect to flow; installing an expansion joint in a location other than as prescribed by the installation drawings; premature removal of shipping devices; springing of bellows to make up for piping misalignment; insufficient protection from mechanical damage due to work in the surrounding area; insufficient protection of bellows during nearby welding operations and failure to remove shipping devices before placing system in operation.

Improper anchoring, guiding and supporting of the system.

Anchor failure in service.

Bellows corrosion, both internal and external.

System over-pressure (in-service or hydrotest). Bellows vibration (mechanical or flow-induced resulting in high cycle fatigue).

Excessive bellows deflection (axial, lateral, angular deflections greater than design values).

Torsion.

Bellows erosion.

Failures can occur for many reasons, but experience has shown that certain causes of failure fall into fairly distinct categories.

Shipping and handling damage. Examples: Denting or gouging of bellows from being struck by hard objects (tools, chain falls, forklifts, adjacent structures, etc.); improper stacking for shipping or storage; insufficient protection from weather or other adverse environmental conditions.

Improper installation and insufficient protection.

During and after installation.

Examples: Joints with internal liners installed in the reverse direction with respect to flow; installing an expansion joint in a location other than as prescribed by the installation drawings; premature removal of shipping devices; springing of bellows to make up for piping misalignment; insufficient protection from mechanical damage due to work in the surrounding area; insufficient protection of bellows during nearby welding operations and failure to remove shipping devices before placing system in operation.

Improper anchoring, guiding and supporting of the system.

Anchor failure in service.

Bellows corrosion, both internal and external.

System over-pressure (in-service or hydrotest). Bellows vibration (mechanical or flow-induced resulting in high cycle fatigue).

Excessive bellows deflection (axial, lateral, angular deflections greater than design values).

Torsion.

Bellows erosion.