We do not air test fabric expansion joints; all welds are liquid penetrant tested.

We do not air test fabric expansion joints; all welds are liquid penetrant tested.

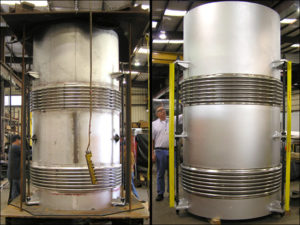

Dye-penetrant tests should be performed in order to check the integrity of the welds. At U.S. Bellows, all bellows undergo a dye-penetrant examination before being shipped to the customer.

At U.S. Bellows, we perform a variety of tests:

Expansion joints are maintenance-free. They can only be tested if the expansion joint is supplied with 2-ply testable bellows using vacuum or air pressure testing.

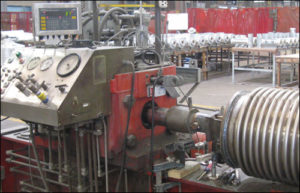

Cracks on a fatigue testing machine are detected by the loss of internal pressure that is shown pressure gauge on the machine.

For pneumatic testing, air is used as the medium for testing and for helium testing they use helium, and the cost for helium is much higher.

A burst test is performed under controlled conditions and pressure is applied over a period of one to two hours using the necessary safety precautions for all personnel involved.

Blotting on a dye-penetrant test typically indicates a crack in the weld. Therefore, the crack would be repaired and the test performed once again.

| Fabric Expansion Joints can withstand up to 3 PSIG (pounds per square inch gauge) or 100″ of water (H₂O) column (In pressure). If the pressure exceeds this amount, it is best to use a metallic expansion joint. |

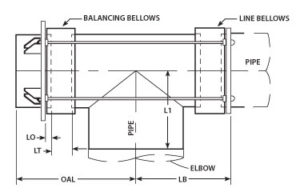

The pressure is equal on both sides for a pressure balanced expansion joint. If the pressure difference is minor, it would not be a problem, but if the pressure thrust is high, then an imbalance of forces would occur and could result in forces being transmitted to adjacent equipment.

The pressure rating is the maximum allowable pressure that the particular expansion joint can absorb. This is determined on a case-by-case basis.

Pressure balance joints balance the pressure thrust forces inside of the expansion joint tie rods.

In an axial piping system, the expansion joint should be located as close as possible to a main anchor. The first pipe guide should be located at a distance of 4 pipe diameters away from the expansion joint. The second guide should be located a distance of 14 pipe diameters away from the first guide. During installation, the expansion joint should be either welded or flanged into the piping system.

Yes, if they are testing just the expansion joint or if they are testing when installed, they have to make sure that the pipe line is anchored or have limit rods added to the expansion joint to absorb the pressure thrust.

The pressure rating an expansion joint can take depends upon pipe size and temperature. Standard units from 3 inches to 24 inches are suitable for 300 PSIG. (pounds per square inch) Higher pressures can be accommodated on a case by case basis.

If the expansion joint is not tied the pressure thrust will act on the turbine exhaust nozzle and the adjacent piping.

The pressure rating is the maximum allowable pressure to be used for that particular expansion joint. Each pressure rating is specified on a case-by-case basis per expansion joint.