US Bellows designed this tied universal elbow expansion joint for a chemical plant in Arkansas. The bellows, pipe, and liner were made from 304 stainless steel and the tie rods and cover from carbon steel. The expansion joint is 30″ in diameter and 134″ center line to center line of the elbow. It is designed for an operating temperature of 450°F at 200 psig and 2″ of axial lateral. All butt welds were 100% x-rayed and the remaining welds were dye penetrant examined. The complete unit was hydrotested prior to shipment.

Featured Product Archives

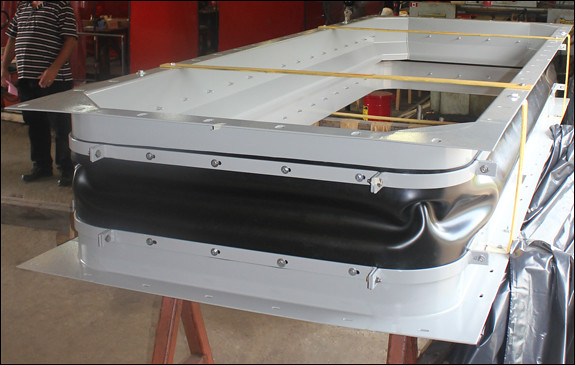

Neoprene Expansion Joints for a Gas Turbine Application

These neoprene expansion joints were designed for a gas turbine application. Each expansion joint is 42″ ID and 7″ OAL. The frame was fabricated from A572 Gr.50 carbon steel, the clamps from 304 stainless steel, and the belt is reinforced neoprene. The expansion joints were designed for -20°F/+200°F with a +/- 100″ water column. A dye penetrant examination on the welds was performed prior to shipment.

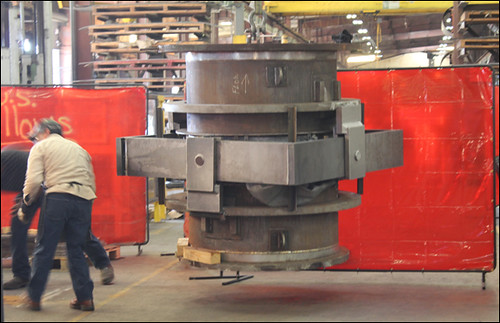

Read MoreGimbal Expansion Joints Designed for a Flare Gas and Steam Application in a Methanol Plant

U.S. Bellows designed these single gimbal expansion joints with floating ring gimbal attachment to the pipe for a flare gas and steam application at a methanol plant in Texas. The bellows were fabricated from Inconel® 625 LCF, the liner and the weld-ends from 316H stainless steel, the cover from 304 stainless steel, and the gimbal structure from A516 carbon steel. The expansion joints are 48″ diameter and are 61 3/8″ in overall length, and are designed for an operating temperature of 752°F at 50 psig. All expansion joints were 100% dye penetrant, X-ray, and hydrotested prior to shipment.

Custom Designed Stainless Steel Tied Universal Expansion Joints

These tied universal expansion joints were custom designed by U.S. Bellows for a pipeline in Connecticut. All components of the expansion joints were fabricated from 316 stainless steel. The job was comprised of units that were 12″ or 16″ in diameter and 60″ in OAL. They are designed for an operating pressure of 10-125 psig at 450°F and a lateral movement of +/- 1″. All of the expansion joints were 100% dye-penetrant tested and hydro-tested at 150 and 175 psig prior to shipment.

Single Expansion Joints Custom Designed for a Hydrocarbon Vapor Pump

| Type: | Single Expansion Joint |

| Size: | 4″ Diameter |

| Material: | 321 Stainless Steel with 304 liners | 105N CS |

| Design | 212°F Operating Temperature |

| Testing: | 100% Dye Penetrant | Hydro-tested |

U.S. Bellows custom designed 4” diameter single expansion joints for a hydrocarbon vapor pumping application in Saudi Arabia. The bellows are fabricated from 321 stainless steel with 304 liners, and the flanges are 105N carbon steel. The expansion joints are designed for 212°F at 53 psig. They are capable of 1.37″ compression, 0.59″ axial, and 0.39″ lateral movement. A hydro-test and dye-penetration exam were performed on the units prior to shipment.

Read More75″ Long Rectangular Expansion Joint Designed for a Boiler Exhaust Application

US Bellows designed and fabricated this rectangular metallic expansion joint for a boiler exhaust application. The expansion joint is 45½” x 75½”. The unit’s bellows, liner, and angle flanges are 304 stainless steel and the cover is carbon steel. The expansion joint is designed for an operating temperature of 500°F at 15 psig. A 100% dye penetrant examination and air and soap leak test was performed prior to shipment.

Read More10″ Dia. Universal Expansion Joints for HVAC Service in California

US Bellows designed these universal expansion joints with flanges for HVAC services in California. The bellows are fabricated from 304 stainless steel, the flanges from A105 carbon steel, and pipe from 106 Gr. B carbon steel. The expansion joints in this project ranged from 3″ to 10″ in diameter, and are designed for an operating temperature of 160°F to 353°F at 120-125 PSIG, with an axial compression of 1.5″ and a lateral deflection of 1.3″. All expansion joints were 100% dye-penetrant tested and hydro-tested prior to shipment.

10′ Long Expansion Joints Designed for a Nuclear Energy Facility

| Type: | Single Expansion Joint |

| Size: | 18″ Diameter and 120″ OAL |

| Material: | 316 Stainless Steel |

| Design | 35 PSIG at an Operating Temperature 1200°F |

| Testing: | 100% Dye Penetrant | Hydro-tested |

US Bellows manufactured these single expansion joints for a nuclear energy facility in Ohio. The expansion joints are 18″ in diameter and 120″ in OAL. All components are fabricated from 316 stainless steel. The assemblies are capable of 1.1″ axial movement, 0.5″ lateral movement, and are designed for 35 psig at an operating temperature of 1200°F. One end is beveled for welding, and the other end is fitted with a special 316 stainless steel clamp assembly. The expansion joints were dye-penetrant tested and hydro-tested prior to shipment.

Read More28″ Dia. Gimbal Expansion Joint Designed with Floating Rings for a Pipeline in Tennessee

This 28″ diameter by 43″ OAL single gimbal expansion joint with a square gimbal box was designed by U.S. Bellows for a pipeline in Tennessee. The bellows are fabricated from Inconel® 625 LCF and the pipe and liners from 316 stainless steel. The expansion joint is designed for an operating temperature of 1250°F at 120 psig. The assembly has a floating ring gimbal design that restrains the pressure thrust. The unit was dye penetrant examined, all welds were 100% X-rayed, PMI, and hydro-tested prior to shipment.

153″ Fabric Expansion Joint for a Gas Turbine Facility

US Bellows designed this fabric expansion joint for a gas turbine application. The dimensions for the expansion joint are 153” x 55” x 21”. The fabric belt is made from reinforced neoprene, while the frame and liner are fabricated from A572 Gr.50 carbon steel. The expansion joint is designed for -20°F/+200°F at +/- 100″ water column. A 100% dye-penetrant examination on the welds was preformed prior to shipment.