| Type: |

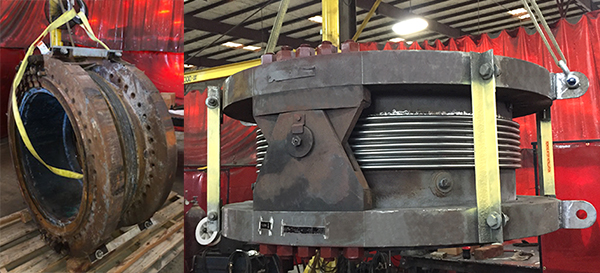

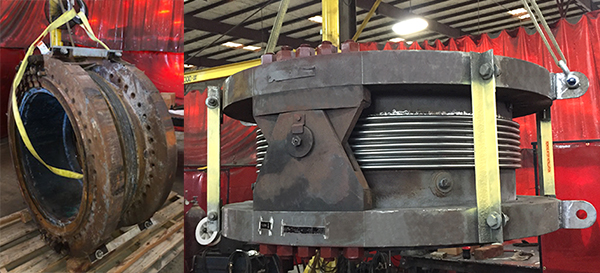

Universal Expansion Joints with Ductwork |

| Size: |

322″ Centerline-to-Centerline | 48″ Diameter |

| Material: |

304 Stainless Steel | Carbon Steel |

| Design |

400°F Operating Temp. @ 91 psig | 3.3″ Lateral |

| Testing: |

100% Dye-Penetrant | PMI | Hydro-tested |

U.S. Bellows custom designed this 26 ft. -10 in. long universal expansion joint with ductwork for a chemical plant. The bellows, ductwork, and flanges were fabricated from 304 stainless steel and the rest of the components from carbon steel. The unit is designed for 48″ diameter piping with an operating temperature of 400°F at 91 psig and 3.3″ of lateral deflection. The expansion joint was completed in 12 weeks and was 100% dye-penetrant, PMI, and hydro-tested before shipment. Chemical plants for which these are typically required process chemicals such as ethylene oxide/glycols, toluene diisocyanate, methylene diphenyl isocyanate, hydrochloric acid, polyether polyols, butanediol, GBL, n-methyl pyrrolidone, tetrahydrofuran, 2-pyrrolidone, PVP/PVPi, specialty amines, aniline, acetylene, surfactants, polytetrahydrofuran, and methylamines. The end products include furniture, automotive antifreeze, foams, carpets, construction, steel pickling, oil well acidizing, biodegradable plastics, lithium-ion battery production, pharmaceuticals, agriculture, gas treatment, water treatment, toothpaste, detergent, spandex fibers, engineered high-performance plastics, and animal feed.

U.S. Bellows has the scale and manufacturing agility to produce expansion joints and ductwork ranging in order size from a small scale of sub-1000 of dollars to upwards of 1M dollar large capital projects. We regularly support overnight lead times and tight project deliverables with evolving project requirements per the client and site needs. Last month, over half of our production capacity, was dedicated to this kind of work. A glimpse into our capabilities is outlined below from some projects we did last year:

– Refurbished 6, 48″-64″ diameter refractory-lined expansion joints for a large Houston refinery during a 45-day turnaround

– Completed a large ducting project for a major chemical facility in Texas with on-time delivery

– In the last 6 months, 40% of our expansion joint jobs have shipped in 2 weeks

We invite you to visit our facility and meet our team to get a first-hand look at our capabilities for your upcoming projects.

US-B REF. ORIGINAL POST 11122019

| Type: |

Universal Expansion Joints with Ductwork |

| Size: |

322″ Centerline-to-Centerline | 48″ Diameter |

| Material: |

304 Stainless Steel | Carbon Steel |

| Design |

400°F Operating Temp. @ 91 psig | 3.3″ Lateral |

| Testing: |

100% Dye-Penetrant | PMI | Hydro-tested |

U.S. Bellows custom designed this 26 ft. -10 in. long universal expansion joint with ductwork for a chemical plant. The bellows, ductwork, and flanges were fabricated from 304 stainless steel and the rest of the components from carbon steel. The unit is designed for 48″ diameter piping with an operating temperature of 400°F at 91 psig and 3.3″ of lateral deflection. The expansion joint was completed in 12 weeks and was 100% dye-penetrant, PMI, and hydro-tested before shipment. Chemical plants for which these are typically required process chemicals such as ethylene oxide/glycols, toluene diisocyanate, methylene diphenyl isocyanate, hydrochloric acid, polyether polyols, butanediol, GBL, n-methyl pyrrolidone, tetrahydrofuran, 2-pyrrolidone, PVP/PVPi, specialty amines, aniline, acetylene, surfactants, polytetrahydrofuran, and methylamines. The end products include furniture, automotive antifreeze, foams, carpets, construction, steel pickling, oil well acidizing, biodegradable plastics, lithium-ion battery production, pharmaceuticals, agriculture, gas treatment, water treatment, toothpaste, detergent, spandex fibers, engineered high-performance plastics, and animal feed.

U.S. Bellows has the scale and manufacturing agility to produce expansion joints and ductwork ranging in order size from a small scale of sub-1000 of dollars to upwards of 1M dollar large capital projects. We regularly support overnight lead times and tight project deliverables with evolving project requirements per the client and site needs. Last month, over half of our production capacity, was dedicated to this kind of work. A glimpse into our capabilities is outlined below from some projects we did last year:

– Refurbished 6, 48″-64″ diameter refractory-lined expansion joints for a large Houston refinery during a 45-day turnaround

– Completed a large ducting project for a major chemical facility in Texas with on-time delivery

– In the last 6 months, 40% of our expansion joint jobs have shipped in 2 weeks

We invite you to visit our facility and meet our team to get a first-hand look at our capabilities for your upcoming projects.

US-B REF. ORIGINAL POST 11122019

Read More

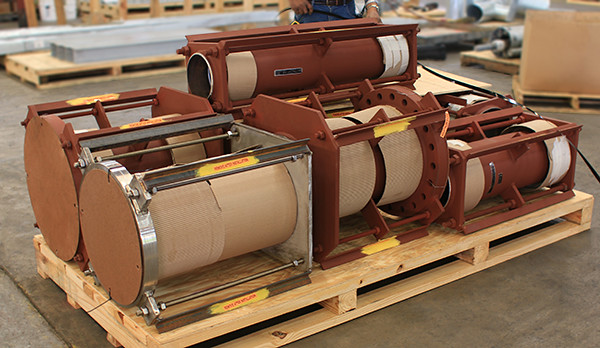

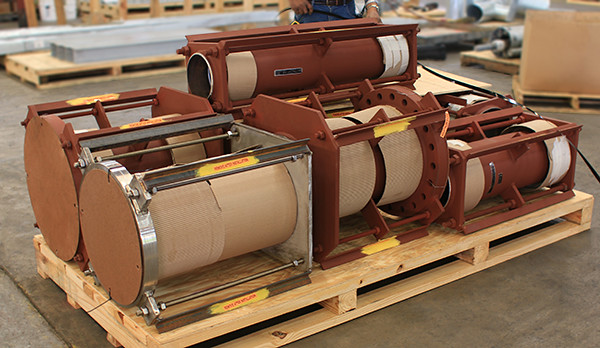

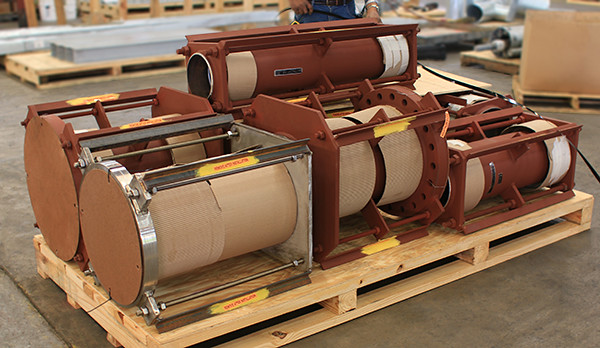

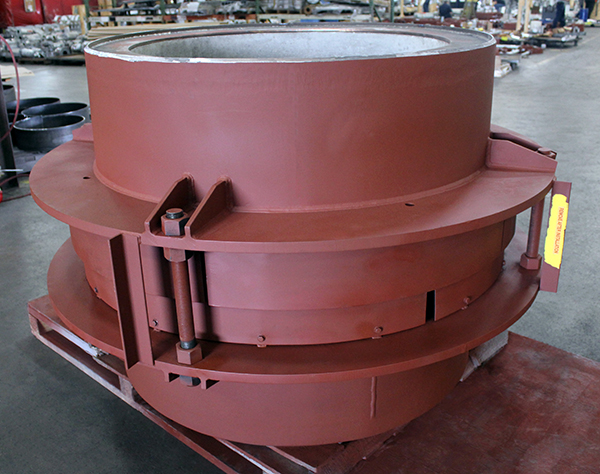

These universal expansion joints were custom-designed with guided tie rods, internal liners, and bellows protection covers for a hot air blower. These expansion joints are used in a plant that manufactures tires for cars and light-duty trucks. High Heat is required in the manufacturing process to vulcanize rubber to components made of steel and polyester and to also cure the rubber. The universal expansion joint can allow for large amounts of lateral deflection that can occur in more than one plane. By increasing or decreasing the distance between the two bellows by varying the length of a section of pipe spool, the designer can accommodate for the given amount of lateral deflection. These expansion joints are designed for an operating pressure of 50 psig at 383 degrees F. A total of 18 were supplied with half of the units measuring 40” dia. x 74-7/8” long x 58-1/2” overall outer dia. The rest measure 36” dia. X 60-1/4” long x 53-3/4” overall outer diameter. The bellows, flange, middle pipe, liner, and lugs are fabricated from 316/316L stainless steel. The rods, nuts, and cover are 316 stainless steel. The 40” dia. unit is designed for 0.394” axial compression and the 36” dia. unit is designed for 0.20” axial compression. Both units are designed for 0.394” lateral movement. Each expansion joint was inspected by quality control and hydraulic pressure tested before shipment. We manufacture expansion joints to relieve stress in piping systems whether the thermal movement is axial, lateral, or angular in plants such as Food Processing, Automotive, Hospital Steam Lines, Semiconductors, and other types of Green Energy plants.

These universal expansion joints were custom-designed with guided tie rods, internal liners, and bellows protection covers for a hot air blower. These expansion joints are used in a plant that manufactures tires for cars and light-duty trucks. High Heat is required in the manufacturing process to vulcanize rubber to components made of steel and polyester and to also cure the rubber. The universal expansion joint can allow for large amounts of lateral deflection that can occur in more than one plane. By increasing or decreasing the distance between the two bellows by varying the length of a section of pipe spool, the designer can accommodate for the given amount of lateral deflection. These expansion joints are designed for an operating pressure of 50 psig at 383 degrees F. A total of 18 were supplied with half of the units measuring 40” dia. x 74-7/8” long x 58-1/2” overall outer dia. The rest measure 36” dia. X 60-1/4” long x 53-3/4” overall outer diameter. The bellows, flange, middle pipe, liner, and lugs are fabricated from 316/316L stainless steel. The rods, nuts, and cover are 316 stainless steel. The 40” dia. unit is designed for 0.394” axial compression and the 36” dia. unit is designed for 0.20” axial compression. Both units are designed for 0.394” lateral movement. Each expansion joint was inspected by quality control and hydraulic pressure tested before shipment. We manufacture expansion joints to relieve stress in piping systems whether the thermal movement is axial, lateral, or angular in plants such as Food Processing, Automotive, Hospital Steam Lines, Semiconductors, and other types of Green Energy plants.

Read More

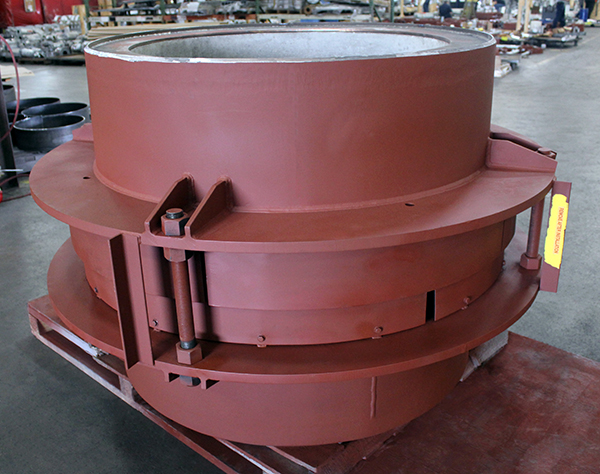

Universal expansion joints such as these are used in chemical plants that manufacture petrochemicals (such as ethylene and styrene monomer), polymers, and building products (PVC profiles for windows, doors, and decking). The units range in length from 26” to 48” and in diameter from 8” to 20”. The bellows were fabricated from 321 stainless steel, the weld ends, pipe spools, and flanges from 304 stainless steel, and the tie rods and hex nuts from carbon steel. They are designed for temperatures ranging from -150°F to 800°F, operating pressures ranging from 50 to 240 PSIG, and 0.25” to 2.25” of lateral deflection. The expansion joints were air, soap, and bubble tested, 100% dye-penetrant tested, and hydro-tested before shipment. The universal pipe expansion joint consists of two bellows separated by a pipe section or spool. The primary purpose of this arrangement is to have a unit that will accept large amounts of lateral deflection. The amount of lateral deflection they can accept is a function of the amount of angulation each bellows can absorb and the distance between the bellows. For a given bellows element, the amount of lateral deflection capability can be increased or decreased by simply changing the length of the center spool.

Universal expansion joints such as these are used in chemical plants that manufacture petrochemicals (such as ethylene and styrene monomer), polymers, and building products (PVC profiles for windows, doors, and decking). The units range in length from 26” to 48” and in diameter from 8” to 20”. The bellows were fabricated from 321 stainless steel, the weld ends, pipe spools, and flanges from 304 stainless steel, and the tie rods and hex nuts from carbon steel. They are designed for temperatures ranging from -150°F to 800°F, operating pressures ranging from 50 to 240 PSIG, and 0.25” to 2.25” of lateral deflection. The expansion joints were air, soap, and bubble tested, 100% dye-penetrant tested, and hydro-tested before shipment. The universal pipe expansion joint consists of two bellows separated by a pipe section or spool. The primary purpose of this arrangement is to have a unit that will accept large amounts of lateral deflection. The amount of lateral deflection they can accept is a function of the amount of angulation each bellows can absorb and the distance between the bellows. For a given bellows element, the amount of lateral deflection capability can be increased or decreased by simply changing the length of the center spool.

Read More

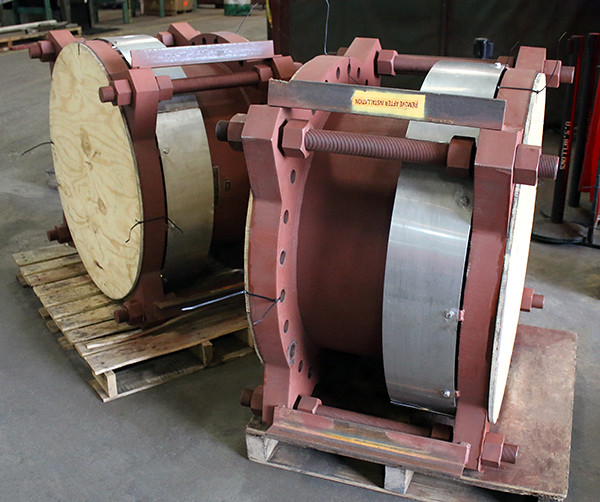

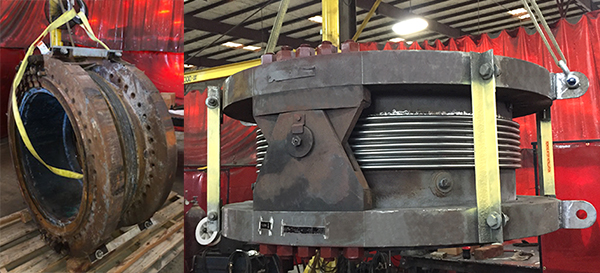

U.S. Bellows custom-designed and fabricated universal gimbal expansion joints for 24” diameter crude oil pipelines at a power plant in Canada. The bellows are fabricated from A240 316 stainless steel bellows, the flanges are A105N carbon steel, and the plates are A516 70 carbon steel. The expansion joints are designed for a 10 degrees angular rotation at 285 psig up to 100 degrees F. They are designed for an angular spring rate of 4900 in-lb/dec and vertical offset of 10-1/4”. The units measure 43” x 43” x 110” and 38” x 38” x 79”.

3D Modeling was done so that our engineers can check the “fit-up” to confirm the design, perform stress analysis, or other modeling benefits prior to fabrication. We performed hydro tests, completed NDE reports, and supplied Material Test Reports per the client requirements.

U.S. Bellows custom-designed and fabricated universal gimbal expansion joints for 24” diameter crude oil pipelines at a power plant in Canada. The bellows are fabricated from A240 316 stainless steel bellows, the flanges are A105N carbon steel, and the plates are A516 70 carbon steel. The expansion joints are designed for a 10 degrees angular rotation at 285 psig up to 100 degrees F. They are designed for an angular spring rate of 4900 in-lb/dec and vertical offset of 10-1/4”. The units measure 43” x 43” x 110” and 38” x 38” x 79”.

3D Modeling was done so that our engineers can check the “fit-up” to confirm the design, perform stress analysis, or other modeling benefits prior to fabrication. We performed hydro tests, completed NDE reports, and supplied Material Test Reports per the client requirements.

Read More

| Type: |

Fabric Expansion Joint |

| Size: |

70″ W x 126″ L x 17.5″ Face-to-Face |

| Material: |

PTFE Fabric Belt | Stainless Steel Framework |

| Design |

Operating Temp: -20°F to 600°F | Operating Pressure +/- 100″ Water Column

Movement +/- 1″ Axial Compression & Lateral Offset Combined |

| Testing: |

Dye Penetrant Examined | Anchor Install Test& Q.C. Inspection |

U.S Bellows custom-designed a rectangular fabric expansion joint with rounded corners for an exhaust duct application at a gas turbine in Saudi, Arabia. The unit is 70″ W x 126″ L x 17.5″ face-to-face; the fabric belt is PTFE and the framework is stainless steel. The expansion joint is designed for an operating temperature range from -20°F to 600°F, an operating pressure of +/- 100″ water column, and a movement of +/- 1″ axial compression and lateral offset combined. A 100% dye-penetrate exam and anchor install test were performed before shipment.

| Type: |

Fabric Expansion Joint |

| Size: |

70″ W x 126″ L x 17.5″ Face-to-Face |

| Material: |

PTFE Fabric Belt | Stainless Steel Framework |

| Design |

Operating Temp: -20°F to 600°F | Operating Pressure +/- 100″ Water Column

Movement +/- 1″ Axial Compression & Lateral Offset Combined |

| Testing: |

Dye Penetrant Examined | Anchor Install Test& Q.C. Inspection |

U.S Bellows custom-designed a rectangular fabric expansion joint with rounded corners for an exhaust duct application at a gas turbine in Saudi, Arabia. The unit is 70″ W x 126″ L x 17.5″ face-to-face; the fabric belt is PTFE and the framework is stainless steel. The expansion joint is designed for an operating temperature range from -20°F to 600°F, an operating pressure of +/- 100″ water column, and a movement of +/- 1″ axial compression and lateral offset combined. A 100% dye-penetrate exam and anchor install test were performed before shipment.

Read More

| Type: |

Refractory-Lined Expansion Joint |

| Size: |

43″ Tall x 39-1/2″ Dia. |

| Material: |

Carbon Steel | INCOLOY® 825 | 3.75″ Thick Refractory |

| Design |

Operating Temp: 653°F at 46 PSIG | 0.25″ Axial Compression |

| Testing: |

Hydro-tested | Q.C. Inspection |

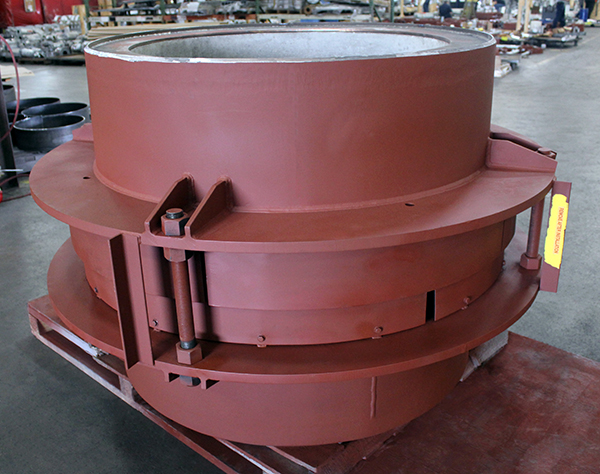

This refractory-lined expansion joint was custom designed for a regenerator application in Uruguay. The unit is 43″ tall, 39-1/2″ in diameter, fabricated from carbon steel and the bellows are INCOLOY® 825. It is lined with 3.75″ thick insulating and abrasion-resistant refractory. It is designed for an operating temperature of 653°F at 46 PSIG and 0.25” axial compression. The expansion joint was hydro-tested at 68 psig prior to shipment.

| Type: |

Refractory-Lined Expansion Joint |

| Size: |

43″ Tall x 39-1/2″ Dia. |

| Material: |

Carbon Steel | INCOLOY® 825 | 3.75″ Thick Refractory |

| Design |

Operating Temp: 653°F at 46 PSIG | 0.25″ Axial Compression |

| Testing: |

Hydro-tested | Q.C. Inspection |

This refractory-lined expansion joint was custom designed for a regenerator application in Uruguay. The unit is 43″ tall, 39-1/2″ in diameter, fabricated from carbon steel and the bellows are INCOLOY® 825. It is lined with 3.75″ thick insulating and abrasion-resistant refractory. It is designed for an operating temperature of 653°F at 46 PSIG and 0.25” axial compression. The expansion joint was hydro-tested at 68 psig prior to shipment.

Read More

| Type: |

Universal Expansion Joints |

| Size: |

48″ Diameter | 77″ FTF |

| Material: |

316 Stainless Steel | Carbon Steel |

| Design |

150°F Operating Temp. @ 25 PSIG | 5.3″ Axial | 2″ Lateral |

| Testing: |

Hydro-tested @ 50 PSIG |

US Bellows custom-designed this universal expansion joint for a crude oil line at an oil refinery in Saudi Arabia. This expansion joint was specially designed with oversized bellows to keep a smooth flow of oil along the line and avoid turbulence. The bellows were fabricated from a 316 stainless steel with all of the other components from carbon steel. The unit is 48″ in diameter and 77″ face-to-face. It is designed for an operating temperature of 150°F at 25 PSIG, 5.3″ of axial compression, and 2″ of lateral deflection. The unit was hydro-tested at 50 PSIG prior to shipment.

| Type: |

Universal Expansion Joints |

| Size: |

48″ Diameter | 77″ FTF |

| Material: |

316 Stainless Steel | Carbon Steel |

| Design |

150°F Operating Temp. @ 25 PSIG | 5.3″ Axial | 2″ Lateral |

| Testing: |

Hydro-tested @ 50 PSIG |

US Bellows custom-designed this universal expansion joint for a crude oil line at an oil refinery in Saudi Arabia. This expansion joint was specially designed with oversized bellows to keep a smooth flow of oil along the line and avoid turbulence. The bellows were fabricated from a 316 stainless steel with all of the other components from carbon steel. The unit is 48″ in diameter and 77″ face-to-face. It is designed for an operating temperature of 150°F at 25 PSIG, 5.3″ of axial compression, and 2″ of lateral deflection. The unit was hydro-tested at 50 PSIG prior to shipment.

Read More

| Type: |

Hinged Expansion Joints |

| Size: |

66″ Diameter | 39 3/8″ OAL |

| Material: |

Incoloy 825 | 321 Stainless Steel |

| Design |

986°F Operating Temp. @ 73 PSIG | 4.25° Angular |

| Testing: |

100% Dye-Penetrant | X-Ray | Hydro-tested |

This single hinged expansion joint was custom-designed for a chemical plant in Saudi Arabia. The bellows were fabricated from Incoloy 825 and the cover, weld-ends, hinges, and liner from 321 stainless steel. The unit is 66″ in diameter and 39 3/8″ OAL. It is designed for an operating temperature of 986°F at 73 PSIG and 4.25° of angular rotation. The expansion joint was 100% dye-penetrant tested, the bellows and pipe longitudinal seam were x-ray tested and hydro-tested prior to shipment.

| Type: |

Hinged Expansion Joints |

| Size: |

66″ Diameter | 39 3/8″ OAL |

| Material: |

Incoloy 825 | 321 Stainless Steel |

| Design |

986°F Operating Temp. @ 73 PSIG | 4.25° Angular |

| Testing: |

100% Dye-Penetrant | X-Ray | Hydro-tested |

This single hinged expansion joint was custom-designed for a chemical plant in Saudi Arabia. The bellows were fabricated from Incoloy 825 and the cover, weld-ends, hinges, and liner from 321 stainless steel. The unit is 66″ in diameter and 39 3/8″ OAL. It is designed for an operating temperature of 986°F at 73 PSIG and 4.25° of angular rotation. The expansion joint was 100% dye-penetrant tested, the bellows and pipe longitudinal seam were x-ray tested and hydro-tested prior to shipment.

Read More

| Type: |

Universal Expansion Joints |

| Size: |

108″ Length | 19.5″ ID |

| Design: |

304 Stainless Steel |

| Material: |

550°F Operating Temperature @ 15 PSIG, 5″ Lateral |

| Testing: |

100% Dye-Penetrant | Air, Soap, & Bubble |

US Bellows custom-designed these tied universal expansion joints for a chemical plant in Texas. The units were completely fabricated from 304 stainless steel and are 108″ long with a 19.5″ ID. They are designed for an operating temperature of 550°F at 15 PSIG, 5″ of lateral deflection. The expansion joints were 100% dye-penetrant tested and air, soap, and bubble-tested prior to shipment.

| Type: |

Universal Expansion Joints |

| Size: |

108″ Length | 19.5″ ID |

| Design: |

304 Stainless Steel |

| Material: |

550°F Operating Temperature @ 15 PSIG, 5″ Lateral |

| Testing: |

100% Dye-Penetrant | Air, Soap, & Bubble |

US Bellows custom-designed these tied universal expansion joints for a chemical plant in Texas. The units were completely fabricated from 304 stainless steel and are 108″ long with a 19.5″ ID. They are designed for an operating temperature of 550°F at 15 PSIG, 5″ of lateral deflection. The expansion joints were 100% dye-penetrant tested and air, soap, and bubble-tested prior to shipment.

Read More

| Type: |

Single Flanged Expansion Joint |

| Size: |

10″ & 14″ NPS | 13″ & 16-1/2″ OAL |

| Material: |

304 Stainless Steel | CS |

| Design |

203°F Operating Temperature |

| Testing: |

100% Dye Penetrant | Hydro-tested |

U.S. Bellows designed these 10″ and 14″ NPS single expansion joints for a pipeline in Oklahoma. They have an overall length of 13″ and 16-1/2″. The bellows, liners, covers, and flanges are fabricated from 304 stainless steel, and the tie rods are carbon steel. They are designed for an operating temperature of 203°F at 15 psig. The expansion joints were 100% dye-penetrant and hydro-tested prior to shipment.

| Type: |

Single Flanged Expansion Joint |

| Size: |

10″ & 14″ NPS | 13″ & 16-1/2″ OAL |

| Material: |

304 Stainless Steel | CS |

| Design |

203°F Operating Temperature |

| Testing: |

100% Dye Penetrant | Hydro-tested |

U.S. Bellows designed these 10″ and 14″ NPS single expansion joints for a pipeline in Oklahoma. They have an overall length of 13″ and 16-1/2″. The bellows, liners, covers, and flanges are fabricated from 304 stainless steel, and the tie rods are carbon steel. They are designed for an operating temperature of 203°F at 15 psig. The expansion joints were 100% dye-penetrant and hydro-tested prior to shipment.

Read More

| Type: |

Rectangular Universal Metallic Expansion Joint |

| Size: |

80″ Long | 60″ Wide |

| Design: |

304 Stainless Steel | Carbon Steel |

| Material: |

Operating Temp. of 170°F @ 25 psig |

| Testing: |

Soap & Air Bubble | 100% Dye-penetrant |

U.S. Bellows custom designed this rectangular universal metallic expansion joint for a refinery in Texas. The unit is 80″ long and 60″ wide. The bellows are fabricated from 304 stainless steel, and the flange and pipe spool are carbon steel. It is designed for an operating temperature of 170°F at 25 psig. The expansion joint was soap and air bubble tested and 100% dye penetrant tested prior to shipment.

| Type: |

Rectangular Universal Metallic Expansion Joint |

| Size: |

80″ Long | 60″ Wide |

| Design: |

304 Stainless Steel | Carbon Steel |

| Material: |

Operating Temp. of 170°F @ 25 psig |

| Testing: |

Soap & Air Bubble | 100% Dye-penetrant |

U.S. Bellows custom designed this rectangular universal metallic expansion joint for a refinery in Texas. The unit is 80″ long and 60″ wide. The bellows are fabricated from 304 stainless steel, and the flange and pipe spool are carbon steel. It is designed for an operating temperature of 170°F at 25 psig. The expansion joint was soap and air bubble tested and 100% dye penetrant tested prior to shipment.

Read More

Expansion Joint Crated for Export

This tied universal expansion joint is fabricated from carbon steel pipe, tie rods and covers, and 304 stainless steel bellows and liners. The overall length of the expansion joint is 72″. The application of this expansion joint is to provide for large lateral movement in a propane dehydrogeneration plant. The expansion joint welds were 100% dye-penetrant examined and hydro-tested prior to shipment

Expansion Joint Crated for Export

This tied universal expansion joint is fabricated from carbon steel pipe, tie rods and covers, and 304 stainless steel bellows and liners. The overall length of the expansion joint is 72″. The application of this expansion joint is to provide for large lateral movement in a propane dehydrogeneration plant. The expansion joint welds were 100% dye-penetrant examined and hydro-tested prior to shipment

Read More

| Type: |

In-line Pressure Balanced Expansion Joint |

| Size: |

38″ F-F | 58-1/2 Diameter |

| Material: |

304 Stainless Steel | Carbon Steel |

| Design: |

725°F @ 14.22 PSIG | 1-1/2″ Axial Compression | 422 lb./in. Spring Rate |

| Testing: |

100% X-Rayed | Dye-penetrant | Air/leak tested |

US Bellows custom-designed these in-line pressure balanced expansion joints for a chemical plant in Texas. They are 38″ face-to-face and 58-1/2″ in diameter. The bellows are fabricated from 304 stainless steel with carbon steel tie rods and flange plates. They are designed for use at 725°F and 14.22 psig, with a spring rate of 422 lb/in. and 1.5″ of axial compression. The expansion joints were 100% dye-penetrant examined and air leak tested prior to shipment.

| Type: |

In-line Pressure Balanced Expansion Joint |

| Size: |

38″ F-F | 58-1/2 Diameter |

| Material: |

304 Stainless Steel | Carbon Steel |

| Design: |

725°F @ 14.22 PSIG | 1-1/2″ Axial Compression | 422 lb./in. Spring Rate |

| Testing: |

100% X-Rayed | Dye-penetrant | Air/leak tested |

US Bellows custom-designed these in-line pressure balanced expansion joints for a chemical plant in Texas. They are 38″ face-to-face and 58-1/2″ in diameter. The bellows are fabricated from 304 stainless steel with carbon steel tie rods and flange plates. They are designed for use at 725°F and 14.22 psig, with a spring rate of 422 lb/in. and 1.5″ of axial compression. The expansion joints were 100% dye-penetrant examined and air leak tested prior to shipment.

Read More

| Type: |

Single Flanged Expansion Joint |

| Size: |

18-1/2″ Long | 8″ Diameter |

| Material: |

304 Stainless Steel | CS |

| Design |

338°F @ 51 PSIG | 1-3/4″ Axial Movement | 225 lb. Spring Rate |

| Testing: |

100% Dye Penetrant | Hydro-tested | X-Rayed |

US Bellows manufactured this single expansion joints for a refinery in Korea. The bellows were fabricated from 304 stainless steel, and the frame from carbon steel. The expansion joint is 8″ in diameter and 18-½” long. It is designed for an operating temperature of 338°F at 51 PSIG, with an axial movement of 1¾”, and a spring rate of 225 lb./in. The bellows were 100% X-rayed, dye-penetrant examined, and hydro-tested prior to shipment.

| Type: |

Single Flanged Expansion Joint |

| Size: |

18-1/2″ Long | 8″ Diameter |

| Material: |

304 Stainless Steel | CS |

| Design |

338°F @ 51 PSIG | 1-3/4″ Axial Movement | 225 lb. Spring Rate |

| Testing: |

100% Dye Penetrant | Hydro-tested | X-Rayed |

US Bellows manufactured this single expansion joints for a refinery in Korea. The bellows were fabricated from 304 stainless steel, and the frame from carbon steel. The expansion joint is 8″ in diameter and 18-½” long. It is designed for an operating temperature of 338°F at 51 PSIG, with an axial movement of 1¾”, and a spring rate of 225 lb./in. The bellows were 100% X-rayed, dye-penetrant examined, and hydro-tested prior to shipment.

Read More

| Type: |

Single Expansion Joints |

| Size: |

24″ F-F | 30″ Diameter |

| Design: |

304 Stainless Steel | Carbon Steel |

| Material: |

800°F @ 275 psig | 1″ Axial Compression |

| Testing: |

Hydro-tested |

These single expansion joints were custom engineered for an oil and gas facility in Texas. The bellows, liner, and cover are fabricated from 304 stainless steel, while the flanges and tie rod assemblies from carbon steel. The units are 30″ in diameter, 24″ face-to-face and include control rods. They are designed for an operating temperature of 800°F at 275 psig and 1″ of axial compression. All expansion joints were hydro-tested prior to shipment.

| Type: |

Single Expansion Joints |

| Size: |

24″ F-F | 30″ Diameter |

| Design: |

304 Stainless Steel | Carbon Steel |

| Material: |

800°F @ 275 psig | 1″ Axial Compression |

| Testing: |

Hydro-tested |

These single expansion joints were custom engineered for an oil and gas facility in Texas. The bellows, liner, and cover are fabricated from 304 stainless steel, while the flanges and tie rod assemblies from carbon steel. The units are 30″ in diameter, 24″ face-to-face and include control rods. They are designed for an operating temperature of 800°F at 275 psig and 1″ of axial compression. All expansion joints were hydro-tested prior to shipment.

Read More

| Type: |

Externally Pressurized Expansion Joints |

| Size: |

36″ I.D. | 56″ OAL | 10″ Face-to-Face |

| Design: |

Hastelloy C-276 Bellows | A36 CS Flanges & Spool |

| Material: |

60 PSIG at 572°F | 9.75″ Axial Compression |

| Testing: |

100% Dye-Penetrant | Hydro-Tested |

U.S. Bellows custom designed externally pressurized expansion joints for a power plant in Venezuela. The units are 56″ in overall length and have a 36″ inside diameter. The bellows are fabricated from Hastelloy C-276 and the flanges and spool are A36 carbon steel. The units are designed for an operating pressure of 60 psig at 572°F and 9.75″ of axial compression. The expansion joints were 100% dye-penetrant tested and hydro-tested prior to shipment.

| Type: |

Externally Pressurized Expansion Joints |

| Size: |

36″ I.D. | 56″ OAL | 10″ Face-to-Face |

| Design: |

Hastelloy C-276 Bellows | A36 CS Flanges & Spool |

| Material: |

60 PSIG at 572°F | 9.75″ Axial Compression |

| Testing: |

100% Dye-Penetrant | Hydro-Tested |

U.S. Bellows custom designed externally pressurized expansion joints for a power plant in Venezuela. The units are 56″ in overall length and have a 36″ inside diameter. The bellows are fabricated from Hastelloy C-276 and the flanges and spool are A36 carbon steel. The units are designed for an operating pressure of 60 psig at 572°F and 9.75″ of axial compression. The expansion joints were 100% dye-penetrant tested and hydro-tested prior to shipment.

Read More

| Type: |

Thick-Wall Flanged & Flued Head Expansion Joints |

| Size: |

52-7/8″ I.D. | 83-5/8″ I.D. | 10″ Face-to-Face |

| Design: |

ASTM A 516-70 Carbon Steel |

| Material: |

250″ Water Column |

| Testing: |

100% Dye-Penetrant | Soap & Air Leak | Hydro-Tested |

U.S. Bellows custom designed thick-wall flanged and flued head expansion joints for a boiler and furnace replacement at a chemical plant in Kentucky. The units were completely fabricated from ASTM A 516-70 carbon steel. The smaller unit’s inside diameter is 52-7/8″ and the larger unit is 83-5/8″. Both units are 10″ face-to-face. They are designed for an operating pressure of 250″ water column. The expansion joints were 100% dye-penetrant tested, soap & air leak tested, and hydro-tested prior shipment.

| Type: |

Thick-Wall Flanged & Flued Head Expansion Joints |

| Size: |

52-7/8″ I.D. | 83-5/8″ I.D. | 10″ Face-to-Face |

| Design: |

ASTM A 516-70 Carbon Steel |

| Material: |

250″ Water Column |

| Testing: |

100% Dye-Penetrant | Soap & Air Leak | Hydro-Tested |

U.S. Bellows custom designed thick-wall flanged and flued head expansion joints for a boiler and furnace replacement at a chemical plant in Kentucky. The units were completely fabricated from ASTM A 516-70 carbon steel. The smaller unit’s inside diameter is 52-7/8″ and the larger unit is 83-5/8″. Both units are 10″ face-to-face. They are designed for an operating pressure of 250″ water column. The expansion joints were 100% dye-penetrant tested, soap & air leak tested, and hydro-tested prior shipment.

Read More

| Type: |

Rectangular Metallic Expansion Joint |

| Size: |

16.5″ x 14.75″ x 12″ F-F |

| Design: |

304 Stainless Steel |

| Material: |

Operating Temp: 800°F @ +/- 20″ WC

1″ Axial Compression | 0.25″ Angular Rotation |

| Testing: |

100% Dye-penetrant tested | Soap & Air Tested |

U.S. Bellows custom designed these rectangular metallic expansion joints for an exhaust duct application in Wisconsin. They are 16.5″ x 14.75″ and 12″ face-to-face. The units are completely fabricated from 304 stainless steel. They are designed for an operating temperature of 800°F at a +/- 20″ water column, with 1″ of axial compression and 0.25 degrees of angular rotation. The expansion joints were 100% dye-penetrant tested and soap & air tested prior to shipment.

| Type: |

Rectangular Metallic Expansion Joint |

| Size: |

16.5″ x 14.75″ x 12″ F-F |

| Design: |

304 Stainless Steel |

| Material: |

Operating Temp: 800°F @ +/- 20″ WC

1″ Axial Compression | 0.25″ Angular Rotation |

| Testing: |

100% Dye-penetrant tested | Soap & Air Tested |

U.S. Bellows custom designed these rectangular metallic expansion joints for an exhaust duct application in Wisconsin. They are 16.5″ x 14.75″ and 12″ face-to-face. The units are completely fabricated from 304 stainless steel. They are designed for an operating temperature of 800°F at a +/- 20″ water column, with 1″ of axial compression and 0.25 degrees of angular rotation. The expansion joints were 100% dye-penetrant tested and soap & air tested prior to shipment.

Read More

| Type: |

Universal Expansion Joint |

| Size: |

24″ Dia. x 48″ F-F | 20″ Dai. x 50″ F-F |

| Material: |

Carbon Steel | 316 Stainless Steel |

| Design: |

Operating Temperature: 180°F

Pressure: 264 PSIG

Movement: 2.75″ Lateral Deflection |

| Testing: |

100% Dye-penetrant tested, X-rayed, Hydro-tested |

These universal expansion joints were designed by U.S. Bellows for a tank farm application in Saudi Arabia. 16 of the units were 24″ dia. x 48″ face-to-face and 8 of the units were 20″ dia. x 50″ face-to-face. The bellows were fabricated from 316 stainless steel with the rest of the components from carbon steel. They are designed for an operating pressure of 264 psig at 180°F with 2.75″ of lateral deflection. The units were 100% dye-penetrant tested, x-rayed and hydro-tested prior to shipment.

| Type: |

Universal Expansion Joint |

| Size: |

24″ Dia. x 48″ F-F | 20″ Dai. x 50″ F-F |

| Material: |

Carbon Steel | 316 Stainless Steel |

| Design: |

Operating Temperature: 180°F

Pressure: 264 PSIG

Movement: 2.75″ Lateral Deflection |

| Testing: |

100% Dye-penetrant tested, X-rayed, Hydro-tested |

These universal expansion joints were designed by U.S. Bellows for a tank farm application in Saudi Arabia. 16 of the units were 24″ dia. x 48″ face-to-face and 8 of the units were 20″ dia. x 50″ face-to-face. The bellows were fabricated from 316 stainless steel with the rest of the components from carbon steel. They are designed for an operating pressure of 264 psig at 180°F with 2.75″ of lateral deflection. The units were 100% dye-penetrant tested, x-rayed and hydro-tested prior to shipment.

Read More

| Type: |

Single Hinged Expansion Joint |

| Size: |

26-3/4″ length x 42-1/2″ diameter |

| Material: |

CS | 304 SS | Inconel 625 LCF | Kaowool |

| Design |

Operating Temperature: 1,100°F

Pressure: 100 PSIG

Movement: 3° of Angular Rotation |

| Testing: |

Hydrotest at 100 PSIG |

U.S. Bellows, Inc. refurbished a 72 year old single hinged expansion joint for a refinery in Louisiana. The expansion joint is 42-1/2″ in diameter and 25-3/4″ in length. The bellows are fabricated from Inconel 625 LCF, the liners are 304H stainless steel, the body is carbon steel and the insulation is Kaowool. The unit is designed for an operating pressure of 100 psig at 1,100°F and 3° angular rotation. A hydro test at 100 psig was conducted prior to shipping the unit after one week.

| Type: |

Single Hinged Expansion Joint |

| Size: |

26-3/4″ length x 42-1/2″ diameter |

| Material: |

CS | 304 SS | Inconel 625 LCF | Kaowool |

| Design |

Operating Temperature: 1,100°F

Pressure: 100 PSIG

Movement: 3° of Angular Rotation |

| Testing: |

Hydrotest at 100 PSIG |

U.S. Bellows, Inc. refurbished a 72 year old single hinged expansion joint for a refinery in Louisiana. The expansion joint is 42-1/2″ in diameter and 25-3/4″ in length. The bellows are fabricated from Inconel 625 LCF, the liners are 304H stainless steel, the body is carbon steel and the insulation is Kaowool. The unit is designed for an operating pressure of 100 psig at 1,100°F and 3° angular rotation. A hydro test at 100 psig was conducted prior to shipping the unit after one week.

Read More