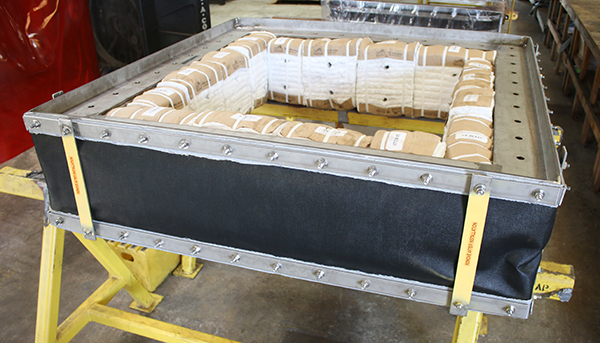

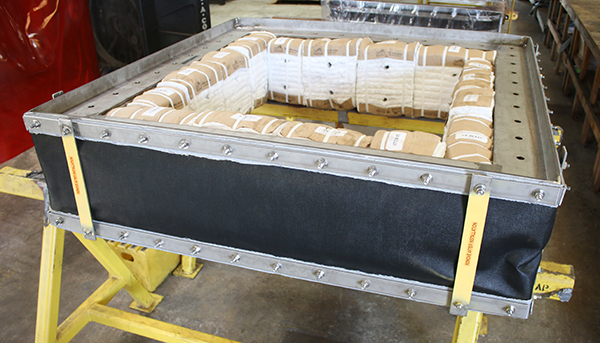

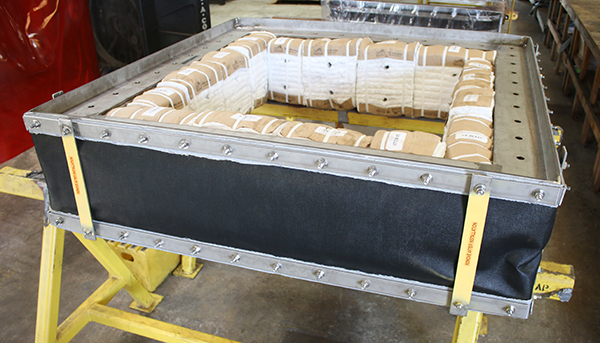

U.S. Bellows, Inc. fabricated rectangular fabric expansion joints for a gas turbine. They are 136″ L x 54″ W 12″ face-to-face. The frame and liner are fabricated from stainless steel and the fabric belt is 1-ply PTFE. The expansion joints are designed for 600°F at +/- 100″ water column.Dye penetrant examination was performed on the welds prior to shipment.

In gas turbine installations, fabric expansion joints are essential for managing the high-temperature exhaust gases that flow from the turbine into downstream components such as heat recovery steam generators (HRSGs), bypass stacks, and emissions control systems. These joints are typically installed in the rectangular ductwork that channels exhaust flow, and they provide the flexibility needed to absorb thermal expansion, vibration, and slight misalignments between components. Because gas turbines operate at extreme temperatures and may cycle frequently, fabric expansion joints are engineered with high-performance materials—such as PTFE, silicone, or high-temp insulation layers—to withstand intense heat, pressure fluctuations, and corrosive gases. Their ability to handle large movements and simplify maintenance access makes them a preferred solution over rigid metal joints in many turbine exhaust applications.

Rectangular fabric expansion joints are a critical component in industrial ducting systems where flexibility, thermal movement, and vibration isolation are essential. These joints are widely used in power plants, refineries, steel mills, cement plants, and other heavy industrial environments—particularly in systems that carry hot gases, air, or exhaust rather than liquids. Their lightweight and flexible design allows them to absorb multi-directional movements and misalignments that occur in large duct systems, especially around boilers, precipitators, scrubbers, and stacks. Fabric joints can be customized with layers of insulation, reinforcement, and protective coatings to handle high temperatures, chemical exposure, and particulate-laden flows—making them a smart, cost-effective solution in challenging service conditions.

PT&P REF. ORIGINAL POST 02162014

U.S. Bellows, Inc. fabricated rectangular fabric expansion joints for a gas turbine. They are 136″ L x 54″ W 12″ face-to-face. The frame and liner are fabricated from stainless steel and the fabric belt is 1-ply PTFE. The expansion joints are designed for 600°F at +/- 100″ water column.Dye penetrant examination was performed on the welds prior to shipment.

In gas turbine installations, fabric expansion joints are essential for managing the high-temperature exhaust gases that flow from the turbine into downstream components such as heat recovery steam generators (HRSGs), bypass stacks, and emissions control systems. These joints are typically installed in the rectangular ductwork that channels exhaust flow, and they provide the flexibility needed to absorb thermal expansion, vibration, and slight misalignments between components. Because gas turbines operate at extreme temperatures and may cycle frequently, fabric expansion joints are engineered with high-performance materials—such as PTFE, silicone, or high-temp insulation layers—to withstand intense heat, pressure fluctuations, and corrosive gases. Their ability to handle large movements and simplify maintenance access makes them a preferred solution over rigid metal joints in many turbine exhaust applications.

Rectangular fabric expansion joints are a critical component in industrial ducting systems where flexibility, thermal movement, and vibration isolation are essential. These joints are widely used in power plants, refineries, steel mills, cement plants, and other heavy industrial environments—particularly in systems that carry hot gases, air, or exhaust rather than liquids. Their lightweight and flexible design allows them to absorb multi-directional movements and misalignments that occur in large duct systems, especially around boilers, precipitators, scrubbers, and stacks. Fabric joints can be customized with layers of insulation, reinforcement, and protective coatings to handle high temperatures, chemical exposure, and particulate-laden flows—making them a smart, cost-effective solution in challenging service conditions.

PT&P REF. ORIGINAL POST 02162014

Read More

| Type: |

Single Flanged Expansion Joint |

| Size: |

6″ to 18″ Dia. Range |

| Material: |

321 Stainless Steel | 304 SS | 316 SS |

| Design |

1055°F | 2 psig | 5/8 ” Axial Travel | 5/8″ Lateral Offse |

| Testing: |

100% Dye-Penetrant | Air, Soap, & Bubble |

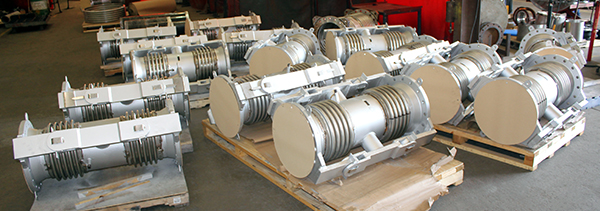

U.S. Bellows provided single expansion joints custom-designed for an oil refinery. The 12″ diameter bellows are fabricated from 321 stainless steel, the liner is 304 stainless and the flanges are fabricated from carbon steel.

Other single type expansion joints for this client’s order varied in diameter from 6″ to 18″, and were constructed using 316 stainless steel for the bellows, liners, and flanges. The design conditions were as follows: a design temperature of 1055°F, an operating pressure of 2 psig, an axial travel of 5/8″, and a lateral offset of 5/8″. Each unit underwent hydrostatic testing before shipment. U.S. Bellows offers expansion joint solutions for a wide range of industries, including biofuels and bioenergy, carbon black, paper mills, sugar mills, and wastewater management.

PT&P REF. ORIGINAL POST 10142020

| Type: |

Single Flanged Expansion Joint |

| Size: |

6″ to 18″ Dia. Range |

| Material: |

321 Stainless Steel | 304 SS | 316 SS |

| Design |

1055°F | 2 psig | 5/8 ” Axial Travel | 5/8″ Lateral Offse |

| Testing: |

100% Dye-Penetrant | Air, Soap, & Bubble |

U.S. Bellows provided single expansion joints custom-designed for an oil refinery. The 12″ diameter bellows are fabricated from 321 stainless steel, the liner is 304 stainless and the flanges are fabricated from carbon steel.

Other single type expansion joints for this client’s order varied in diameter from 6″ to 18″, and were constructed using 316 stainless steel for the bellows, liners, and flanges. The design conditions were as follows: a design temperature of 1055°F, an operating pressure of 2 psig, an axial travel of 5/8″, and a lateral offset of 5/8″. Each unit underwent hydrostatic testing before shipment. U.S. Bellows offers expansion joint solutions for a wide range of industries, including biofuels and bioenergy, carbon black, paper mills, sugar mills, and wastewater management.

PT&P REF. ORIGINAL POST 10142020

Read More

| Type: |

Rectangular Fabric Expansion Joint |

| Size: |

153″ long x 55″ wide x 21″ face-to-face |

| Material: |

PTFE fiber glass reinforced / A572 Gr.50 high strength steel frame & liner |

| Design: |

-20°F to +200°F at +/- 100″ water column |

| Testing: |

100% Dye-Penetrant |

U.S. Bellows designed this rectangular fabric expansion joint for a ventilation air filter system at a gas turbine facility. The dimensions for the expansion joint are 153" long x 55" wide x 21" face-to-face. The fabric belt is made from PTFE fiber glass reinforced, while the frame and liner are fabricated from A572 Gr.50 high strength steel. The expansion joint is designed for -20°F to +200°F at +/- 100" water column. A dye penetrant examination on the welds was performed prior to shipment.

PT&P REF. ORIGINAL POST 10182016

| Type: |

Rectangular Fabric Expansion Joint |

| Size: |

153″ long x 55″ wide x 21″ face-to-face |

| Material: |

PTFE fiber glass reinforced / A572 Gr.50 high strength steel frame & liner |

| Design: |

-20°F to +200°F at +/- 100″ water column |

| Testing: |

100% Dye-Penetrant |

U.S. Bellows designed this rectangular fabric expansion joint for a ventilation air filter system at a gas turbine facility. The dimensions for the expansion joint are 153" long x 55" wide x 21" face-to-face. The fabric belt is made from PTFE fiber glass reinforced, while the frame and liner are fabricated from A572 Gr.50 high strength steel. The expansion joint is designed for -20°F to +200°F at +/- 100" water column. A dye penetrant examination on the welds was performed prior to shipment.

PT&P REF. ORIGINAL POST 10182016

Read More

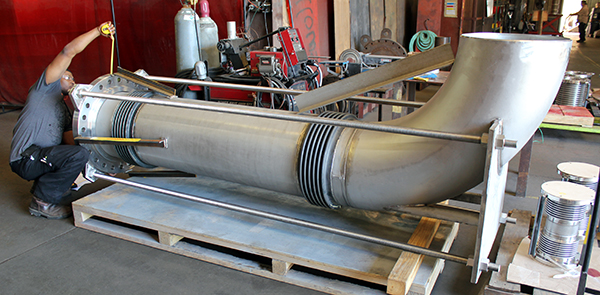

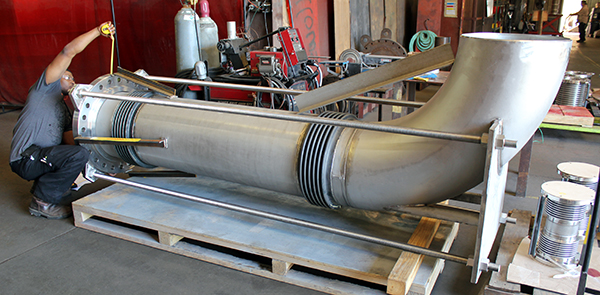

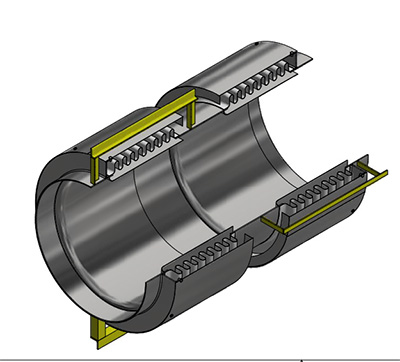

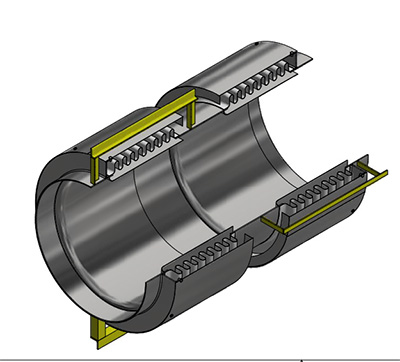

| Type: |

Universal Gimbal Expansion Joint |

| Size: |

102″ – 133″ L | 41.5″ W | 41.75″ H | 32″ diameter |

| Material: |

Carbon Steel | 304 Stainless Steel |

| Design: |

100°F @ 285 psig | 102 lb/in/degree Rotational

Spring Rate | 15.4″ Lateral Deflection |

| Testing: |

Hydrotested @ 428 PSIG |

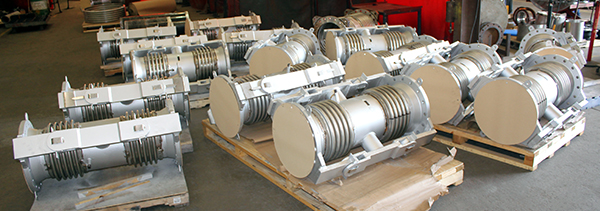

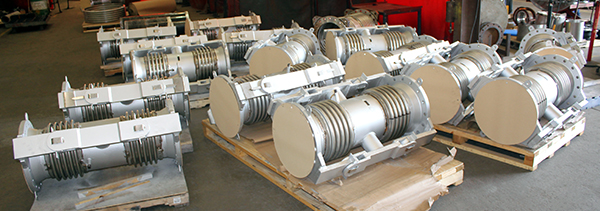

U.S. Bellows custom designed these universal gimbal expansion joints for an oil refinery in Canada. The bellows and liners are fabricated from 304 stainless steel, and the remainder of the components are fabricated from carbon steel. The units range from 102" to 133" long respectively, and sizes supplied are 12"NPS with a gimbal box 27" wide, 27.5" tall and 24"NPS with a gimbal box 41.25" wide, 41.75" tall. They are designed for an operating temperature of 100°F at 285 psig, with a 102 lb/in/degree rotational spring rate and 15.4" of lateral deflection. The expansion joints were 100% dye-penetrant tested and hydro-tested at 428 psig prior to shipment.

Gimbal expansion joints are used in a variety of industrial applications where piping systems experience multidirectional movements due to thermal expansion, vibrations, or other external forces. Here are some common areas where gimbal expansion joints are utilized:

Power Plants: In both fossil fuel and nuclear power plants, gimbal expansion joints are used in the steam, water, and exhaust systems to accommodate thermal expansion and prevent stress on the piping.

Refineries and Petrochemical Plants: These joints are essential in refineries and petrochemical facilities to manage the thermal expansion in pipelines carrying various fluids, including high-temperature hydrocarbons, to ensure safe and efficient operations.

Oil and Gas Industry: Gimbal expansion joints are employed in pipelines that transport oil, gas, and other fluids, especially in offshore drilling platforms, to handle the dynamic movements caused by waves, currents, and thermal effects.

Shipbuilding: In marine applications, gimbal expansion joints are used in the exhaust systems of ships to absorb vibrations and accommodate thermal expansion caused by the operation of engines and other machinery.

Aerospace and Defense: These joints are also found in aerospace applications, such as in rocket propulsion systems, to absorb the significant thermal expansion and mechanical stresses during launch and flight.

PT&P REF. ORIGINAL POST 10012018

| Type: |

Universal Gimbal Expansion Joint |

| Size: |

102″ – 133″ L | 41.5″ W | 41.75″ H | 32″ diameter |

| Material: |

Carbon Steel | 304 Stainless Steel |

| Design: |

100°F @ 285 psig | 102 lb/in/degree Rotational

Spring Rate | 15.4″ Lateral Deflection |

| Testing: |

Hydrotested @ 428 PSIG |

U.S. Bellows custom designed these universal gimbal expansion joints for an oil refinery in Canada. The bellows and liners are fabricated from 304 stainless steel, and the remainder of the components are fabricated from carbon steel. The units range from 102" to 133" long respectively, and sizes supplied are 12"NPS with a gimbal box 27" wide, 27.5" tall and 24"NPS with a gimbal box 41.25" wide, 41.75" tall. They are designed for an operating temperature of 100°F at 285 psig, with a 102 lb/in/degree rotational spring rate and 15.4" of lateral deflection. The expansion joints were 100% dye-penetrant tested and hydro-tested at 428 psig prior to shipment.

Gimbal expansion joints are used in a variety of industrial applications where piping systems experience multidirectional movements due to thermal expansion, vibrations, or other external forces. Here are some common areas where gimbal expansion joints are utilized:

Power Plants: In both fossil fuel and nuclear power plants, gimbal expansion joints are used in the steam, water, and exhaust systems to accommodate thermal expansion and prevent stress on the piping.

Refineries and Petrochemical Plants: These joints are essential in refineries and petrochemical facilities to manage the thermal expansion in pipelines carrying various fluids, including high-temperature hydrocarbons, to ensure safe and efficient operations.

Oil and Gas Industry: Gimbal expansion joints are employed in pipelines that transport oil, gas, and other fluids, especially in offshore drilling platforms, to handle the dynamic movements caused by waves, currents, and thermal effects.

Shipbuilding: In marine applications, gimbal expansion joints are used in the exhaust systems of ships to absorb vibrations and accommodate thermal expansion caused by the operation of engines and other machinery.

Aerospace and Defense: These joints are also found in aerospace applications, such as in rocket propulsion systems, to absorb the significant thermal expansion and mechanical stresses during launch and flight.

PT&P REF. ORIGINAL POST 10012018

Read More

| Type: |

Fabric Expansion Joint |

| Size: |

36″ L | 24-1/2″ W | 24-1/2″ L |

| Material: |

1-Ply ReinForced Silicone Fabric | Carbon Steel |

| Design: |

300°F @ 3 psig | 6″ Lateral Movement |

| Testing: |

100% Dye-Penetrant |

U.S. Bellows designed fabric expansion joint for a textile sheets, polymer, and fiber plant in Virginia. The dimensions for the expansion joints are 36" long, 24-1/2" wide, and 24-1/2" long. These fabric expansion joints are fabricated of carbon steel flanges with 1-ply reinforced silicone fabric. The expansion joints are designed for 300°F with an operating pressure of 3 psig, and movement of 6" lateral. A dye penetrant examination on the welds was performed prior to shipment.

Fabric expansion joints are used in a wide array of applications playing a crucial role in preventing damage to equipment, ensuring system reliability, and maintaining overall safety in industrial processes. Some examples of where they are used are:

- Cement plants for ducts and exhaust systems associated with high temperature operations.

- Mining industry for mineral and material handling including smelting.

- HVAC systems for duct work to address any thermal movements or vibrations.

- Marine and shipbuilding applications where exhaust systems, engine piping and other critical areas movement and vibrations must be managed.

- Renewable energy facilities such a waste to energy or bioenergy plants in which the incineration operations are critical.

- Paper and Pulp mills for ducting systems in drying and paper manufacturing processes.

- Steel Mills for blast furnace systems and exhausting ducts.

- Chemical plants to handle dynamic forces associated with chemical reactions, temperature variations and corrosive environments.

- Power plants Fossil Fuel and Nuclear plants to manage vibrations and thermal axial expansion that could stress components and fixed equipment.

We have a 24/7 field service team that works on fabric expansion joints. One of our loyal customers, a North American-based energy company, reached out to us for warranty work on one of our Fabric Expansion Joints and our fierce Fabric Expansion Joint team lead, stepped in and stepped up! She flew up to West Virginia and completed the work. We are dedicated to the success of our products in the field even after they leave our plant.

PT&P REF. ORIGINAL POST 02052019

| Type: |

Fabric Expansion Joint |

| Size: |

36″ L | 24-1/2″ W | 24-1/2″ L |

| Material: |

1-Ply ReinForced Silicone Fabric | Carbon Steel |

| Design: |

300°F @ 3 psig | 6″ Lateral Movement |

| Testing: |

100% Dye-Penetrant |

U.S. Bellows designed fabric expansion joint for a textile sheets, polymer, and fiber plant in Virginia. The dimensions for the expansion joints are 36" long, 24-1/2" wide, and 24-1/2" long. These fabric expansion joints are fabricated of carbon steel flanges with 1-ply reinforced silicone fabric. The expansion joints are designed for 300°F with an operating pressure of 3 psig, and movement of 6" lateral. A dye penetrant examination on the welds was performed prior to shipment.

Fabric expansion joints are used in a wide array of applications playing a crucial role in preventing damage to equipment, ensuring system reliability, and maintaining overall safety in industrial processes. Some examples of where they are used are:

- Cement plants for ducts and exhaust systems associated with high temperature operations.

- Mining industry for mineral and material handling including smelting.

- HVAC systems for duct work to address any thermal movements or vibrations.

- Marine and shipbuilding applications where exhaust systems, engine piping and other critical areas movement and vibrations must be managed.

- Renewable energy facilities such a waste to energy or bioenergy plants in which the incineration operations are critical.

- Paper and Pulp mills for ducting systems in drying and paper manufacturing processes.

- Steel Mills for blast furnace systems and exhausting ducts.

- Chemical plants to handle dynamic forces associated with chemical reactions, temperature variations and corrosive environments.

- Power plants Fossil Fuel and Nuclear plants to manage vibrations and thermal axial expansion that could stress components and fixed equipment.

We have a 24/7 field service team that works on fabric expansion joints. One of our loyal customers, a North American-based energy company, reached out to us for warranty work on one of our Fabric Expansion Joints and our fierce Fabric Expansion Joint team lead, stepped in and stepped up! She flew up to West Virginia and completed the work. We are dedicated to the success of our products in the field even after they leave our plant.

PT&P REF. ORIGINAL POST 02052019

Read More

U.S. Bellows designed these hinged universal fabric expansion joints for a chemical plant in Delaware. The expansion joints are 84″ in diameter and 60″ OAL. The fabric belt is made with PTFE while the rest of the components are from carbon steel. The expansion joints are designed for an operating temperature of 650°F at 1 psig and 1/2″ of angular movement. The units were 100% dye-penetrate examined was performed prior to shipment.

PT&P REF. ORIGINAL POST 02292016

U.S. Bellows designed these hinged universal fabric expansion joints for a chemical plant in Delaware. The expansion joints are 84″ in diameter and 60″ OAL. The fabric belt is made with PTFE while the rest of the components are from carbon steel. The expansion joints are designed for an operating temperature of 650°F at 1 psig and 1/2″ of angular movement. The units were 100% dye-penetrate examined was performed prior to shipment.

PT&P REF. ORIGINAL POST 02292016

Read More

| Type: |

Externally Pressurized Expansion Joint |

| Size: |

133 11/16″ and 120.5″ Long | Both Have 42″ Pipe Dia. |

| Design: |

Inconel 625 | Carbon Steel |

| Material: |

450°F at 108 psig & 31″ and 25″ Axial Compression |

| Testing: |

Hydro-tested at 167, PMI, 100% X-Ray, and Dye-Penetrant |

U.S. Bellows custom designed these externally pressurized expansion joints for a flare header application at a refinery in Mississippi. One unit measures 133-11/16" long and the other measures 120-1/2" long and both are manufactured for a 42" pipe diameter. The bellows were fabricated from Inconel 625 and used in conjunction with a carbon steel pipe per A671-CC-60 CL.22. The carbon steel pipe is finished with a 2-coat paint system for corrosion protection. They are manufactured for a design pressure of 108 psig at 450°F with 31" and 25" of axial compression. All alloy material was PMI inspected. The units were hydro tested at 167 psig, 100% dye-penetrant tested, and the bellows and pipe weld seams were 100% X-ray tested prior to shipment.

Expansion joint applications are varied depending on the type of plant. Some applications include:

- Exhaust systems for Aerospace, Trucks, Marine Piping

- Solid waste incineration for Renewables and Biofuel plants

- Waste Water Treatment plants for Municipal water districts as well as manufacturing plants

- Kilns in Mining, Food, and Plastics plants

- Geothermal Plants

- Gas Turbines

- FCC units

- Heat exchangers

- Steam distribution in Geothermal plants

- Water cooling systems for Nuclear power plants such as inlet of condenser cooling water from lakes or large bodies of water

- Thermal Oxidizer systems in polymer processing

- Boller Duct Expansions

- Vacuum Jacketed piping systems in LNG

We have built, supplied, installed, replaced, audited, repaired, and tested expansion joints for most piping systems applications. Our in-house expertise in handling different types of materials needed for expansion joints made of carbon steel, stainless, alloy steel, high nickel alloys, and aluminum spans over our 48 years of work. Welding specialties include TIG, pulse-arc MIG, SMAW, SUB-ARC, and Aluminium. Our qualifications for expansion joints are ASME Section IX, AWS D1.1, NS, and MIL-STD-248. Testing can specified to include any or all of the following depending on project and application requirements:

- magnetic particle-dry method

- Liquid penetrant-visible and fluorescent

- Ultrasonic and radiography

- Hydrostatic and Pneumatic testing

US Bellows, a subsidiary of Piping Technology and Products, is a member of the EJMA association which maintains a set of standards for quality expansion joint design and manufacturing. The standards are used as a worldwide reference for the proper selection and application of expansion joints.

PT&P REF. ORIGINAL POST 02202018

| Type: |

Externally Pressurized Expansion Joint |

| Size: |

133 11/16″ and 120.5″ Long | Both Have 42″ Pipe Dia. |

| Design: |

Inconel 625 | Carbon Steel |

| Material: |

450°F at 108 psig & 31″ and 25″ Axial Compression |

| Testing: |

Hydro-tested at 167, PMI, 100% X-Ray, and Dye-Penetrant |

U.S. Bellows custom designed these externally pressurized expansion joints for a flare header application at a refinery in Mississippi. One unit measures 133-11/16" long and the other measures 120-1/2" long and both are manufactured for a 42" pipe diameter. The bellows were fabricated from Inconel 625 and used in conjunction with a carbon steel pipe per A671-CC-60 CL.22. The carbon steel pipe is finished with a 2-coat paint system for corrosion protection. They are manufactured for a design pressure of 108 psig at 450°F with 31" and 25" of axial compression. All alloy material was PMI inspected. The units were hydro tested at 167 psig, 100% dye-penetrant tested, and the bellows and pipe weld seams were 100% X-ray tested prior to shipment.

Expansion joint applications are varied depending on the type of plant. Some applications include:

- Exhaust systems for Aerospace, Trucks, Marine Piping

- Solid waste incineration for Renewables and Biofuel plants

- Waste Water Treatment plants for Municipal water districts as well as manufacturing plants

- Kilns in Mining, Food, and Plastics plants

- Geothermal Plants

- Gas Turbines

- FCC units

- Heat exchangers

- Steam distribution in Geothermal plants

- Water cooling systems for Nuclear power plants such as inlet of condenser cooling water from lakes or large bodies of water

- Thermal Oxidizer systems in polymer processing

- Boller Duct Expansions

- Vacuum Jacketed piping systems in LNG

We have built, supplied, installed, replaced, audited, repaired, and tested expansion joints for most piping systems applications. Our in-house expertise in handling different types of materials needed for expansion joints made of carbon steel, stainless, alloy steel, high nickel alloys, and aluminum spans over our 48 years of work. Welding specialties include TIG, pulse-arc MIG, SMAW, SUB-ARC, and Aluminium. Our qualifications for expansion joints are ASME Section IX, AWS D1.1, NS, and MIL-STD-248. Testing can specified to include any or all of the following depending on project and application requirements:

- magnetic particle-dry method

- Liquid penetrant-visible and fluorescent

- Ultrasonic and radiography

- Hydrostatic and Pneumatic testing

US Bellows, a subsidiary of Piping Technology and Products, is a member of the EJMA association which maintains a set of standards for quality expansion joint design and manufacturing. The standards are used as a worldwide reference for the proper selection and application of expansion joints.

PT&P REF. ORIGINAL POST 02202018

Read More

| Type: |

Fabric Expansion Joint |

| Size: |

143″ long x 61″ wide x 12″ face-to-face |

| Material: |

PTFE Fiberglass Reinforced Fabric Belt & 304 Stainless Steel |

| Design: |

-20°F to 600°F , +/- 100″ water column, 0.5″ Axial & 1″ Lateral |

| Testing: |

Dye-Penetrant |

U.S. Bellows fabricated this rectangular fabric expansion joint for an inlet duct application at a gas turbine facility. The unit is 143″ long x 61″ wide x 12″ face-to-face. The fabric belt is made from reinforced PTFE fiberglass and the frame and liner from 304 stainless steel. It is designed for an operating temperature ranging from -20°F to 600°F with a pressure of +/- 100″ water column, with 0.5″ of axial compression and 1″ of lateral deflection. A dye-penetrant examination was performed on all the structural frame welds prior to shipment.

Fabric expansion joints are used in a wide array of applications playing a crucial role in preventing damage to equipment, ensuring system reliability, and maintaining overall safety in industrial processes. Some examples of where they are used are:

-

- Cement plants for ducts and exhaust systems associated with high temperature operations.

-

- Mining industry for mineral and material handling including smelting.

-

- HVAC systems for duct work to address any thermal movements or vibrations.

-

- Marine and shipbuilding applications where exhaust systems, engine piping and other critical areas movement and vibrations must be managed.

-

- Renewable energy facilities such a waste to energy or bioenergy plants in which the incineration operations are critical.

-

- Paper and Pulp mills for ducting systems in drying and paper manufacturing processes.

-

- Steel Mills for blast furnace systems and exhausting ducts

-

- Chemical plants to handle dynamic forces associated with chemical reactions, temperature variations and corrosive environments.

- Power plants: Fossil Fuel and Nuclear plants to manage vibrations and thermal axial expansion that could stress components and fixed equipment.

PT&P REF. ORIGINAL POST 06252018

| Type: |

Fabric Expansion Joint |

| Size: |

143″ long x 61″ wide x 12″ face-to-face |

| Material: |

PTFE Fiberglass Reinforced Fabric Belt & 304 Stainless Steel |

| Design: |

-20°F to 600°F , +/- 100″ water column, 0.5″ Axial & 1″ Lateral |

| Testing: |

Dye-Penetrant |

U.S. Bellows fabricated this rectangular fabric expansion joint for an inlet duct application at a gas turbine facility. The unit is 143″ long x 61″ wide x 12″ face-to-face. The fabric belt is made from reinforced PTFE fiberglass and the frame and liner from 304 stainless steel. It is designed for an operating temperature ranging from -20°F to 600°F with a pressure of +/- 100″ water column, with 0.5″ of axial compression and 1″ of lateral deflection. A dye-penetrant examination was performed on all the structural frame welds prior to shipment.

Fabric expansion joints are used in a wide array of applications playing a crucial role in preventing damage to equipment, ensuring system reliability, and maintaining overall safety in industrial processes. Some examples of where they are used are:

-

- Cement plants for ducts and exhaust systems associated with high temperature operations.

-

- Mining industry for mineral and material handling including smelting.

-

- HVAC systems for duct work to address any thermal movements or vibrations.

-

- Marine and shipbuilding applications where exhaust systems, engine piping and other critical areas movement and vibrations must be managed.

-

- Renewable energy facilities such a waste to energy or bioenergy plants in which the incineration operations are critical.

-

- Paper and Pulp mills for ducting systems in drying and paper manufacturing processes.

-

- Steel Mills for blast furnace systems and exhausting ducts

-

- Chemical plants to handle dynamic forces associated with chemical reactions, temperature variations and corrosive environments.

- Power plants: Fossil Fuel and Nuclear plants to manage vibrations and thermal axial expansion that could stress components and fixed equipment.

PT&P REF. ORIGINAL POST 06252018

Read More

| Type: |

Fabric Expansion Joint |

| Size: |

20″ Diameter & 18″ Length |

| Material: |

1-Ply PTFE Fabric Belt/Carbon Steel Framework |

| Design: |

-20°F/+600°F with a +/- 20″ Water Column, and +/- 1″ of Axial Compression & Lateral Offset |

| Testing: |

100% Dye-Penetrant |

U.S Bellows fabricated these fabric expansion joints for a carbon gas application at an oil and gas facility in Louisiana. These units are 20″ in diameter and 18" in length. The 1-ply fabric belt is made from PTFE, and the framework is carbon steel. They are designed for an operating temperature of -20°F/+600°F with a +/- 20" water column and +/- 1" of axial compression and lateral offset. The welds of the units were dye penetrant tested prior to shipment.

US Bellows and its subsidiaries have served as leading global suppliers of carbon black worldwide. Material from these plants is made to exacting standards for tires, coatings, ink, batteries, plastics, and numerous other specialty high-performance applications. Carbon black is produced from the thermal decomposition of heavy petroleum raw materials, such as coal tar, ethylene cracking tar, or FCC tar. It is widely utilized owing to its various beneficial characteristics, including surging tire tread wear and rolling resistance, effectively absorbing ultraviolet (UV) light and converting it into heat, improved thermal conductivity, and superior UV protection. Several processes, such as oil furnaces and thermal, are mainly used to manufacture carbon black. In addition to providing expansion joints, we have provided the following products from our portfolio of manufactured in our facility in Houston, Texas:

- Constant Spring Hangers

- Metallic Expansion Joints

- Pipe Shoes, Guides, and Anchors

- Insulated Supports

- Paddle Blinds and Spacers

- Pipe Hangers Hardware

- Slide Bearing Plates

- Instrument Supports

- Variable Spring Hangers

PT&P REF. ORIGINAL POST 08122017

| Type: |

Fabric Expansion Joint |

| Size: |

20″ Diameter & 18″ Length |

| Material: |

1-Ply PTFE Fabric Belt/Carbon Steel Framework |

| Design: |

-20°F/+600°F with a +/- 20″ Water Column, and +/- 1″ of Axial Compression & Lateral Offset |

| Testing: |

100% Dye-Penetrant |

U.S Bellows fabricated these fabric expansion joints for a carbon gas application at an oil and gas facility in Louisiana. These units are 20″ in diameter and 18" in length. The 1-ply fabric belt is made from PTFE, and the framework is carbon steel. They are designed for an operating temperature of -20°F/+600°F with a +/- 20" water column and +/- 1" of axial compression and lateral offset. The welds of the units were dye penetrant tested prior to shipment.

US Bellows and its subsidiaries have served as leading global suppliers of carbon black worldwide. Material from these plants is made to exacting standards for tires, coatings, ink, batteries, plastics, and numerous other specialty high-performance applications. Carbon black is produced from the thermal decomposition of heavy petroleum raw materials, such as coal tar, ethylene cracking tar, or FCC tar. It is widely utilized owing to its various beneficial characteristics, including surging tire tread wear and rolling resistance, effectively absorbing ultraviolet (UV) light and converting it into heat, improved thermal conductivity, and superior UV protection. Several processes, such as oil furnaces and thermal, are mainly used to manufacture carbon black. In addition to providing expansion joints, we have provided the following products from our portfolio of manufactured in our facility in Houston, Texas:

- Constant Spring Hangers

- Metallic Expansion Joints

- Pipe Shoes, Guides, and Anchors

- Insulated Supports

- Paddle Blinds and Spacers

- Pipe Hangers Hardware

- Slide Bearing Plates

- Instrument Supports

- Variable Spring Hangers

PT&P REF. ORIGINAL POST 08122017

Read More

| Type: |

Fabric Expansion Joints |

| Size: |

67″ Long x 67″ Wide x 14″ Tall |

| Material: |

3-Layer Fabric Belt with Kaowool Insulation

304 Stainless Steel Angle Flanges |

| Design |

Operating Temp: 2012°F at +/- 100″ Water Column

1″ of Lateral Deflection |

| Testing: |

100% Dye Penetrant Testing & Q.C. Inspection |

Fabric pipe expansion joints are often used in ducts that carry hot gasses at low pressures. The major design parameters are the temperatures and flow rates of the gasses and the amount and abrasiveness of solids suspended in the gasses. This fabric expansion joint utilizes a bulky flexible material, also called an Insulation Pillow, to shield against high temperatures protecting the belting material. Refractory is also used in the construction of this joint but is designed so that it does not interfere with movement. Our experienced engineers know that every element of this expansion joint plays a role in its rating for certain temperatures and the number of hours of operation. View Fabric Expansion Joints Product Section.

Fabric expansion joints are key in the systems supporting power and refining plants focused around renewable carbon-neutral product offerings. We have worked with the new entrants in the marketplace but also helped our long-term clients transition their older fossil fuel-based assets to green technology. These plants include biochar from biomass processing, carbon black, clean hydrogen, styrene, and cement.

PT&P REF. ORIGINAL POST 03182020

| Type: |

Fabric Expansion Joints |

| Size: |

67″ Long x 67″ Wide x 14″ Tall |

| Material: |

3-Layer Fabric Belt with Kaowool Insulation

304 Stainless Steel Angle Flanges |

| Design |

Operating Temp: 2012°F at +/- 100″ Water Column

1″ of Lateral Deflection |

| Testing: |

100% Dye Penetrant Testing & Q.C. Inspection |

Fabric pipe expansion joints are often used in ducts that carry hot gasses at low pressures. The major design parameters are the temperatures and flow rates of the gasses and the amount and abrasiveness of solids suspended in the gasses. This fabric expansion joint utilizes a bulky flexible material, also called an Insulation Pillow, to shield against high temperatures protecting the belting material. Refractory is also used in the construction of this joint but is designed so that it does not interfere with movement. Our experienced engineers know that every element of this expansion joint plays a role in its rating for certain temperatures and the number of hours of operation. View Fabric Expansion Joints Product Section.

Fabric expansion joints are key in the systems supporting power and refining plants focused around renewable carbon-neutral product offerings. We have worked with the new entrants in the marketplace but also helped our long-term clients transition their older fossil fuel-based assets to green technology. These plants include biochar from biomass processing, carbon black, clean hydrogen, styrene, and cement.

PT&P REF. ORIGINAL POST 03182020

Read More

| Type: |

Neoprene Expansion Joint |

| Size: |

3×10, 6×10, 8×12, 10×14 |

| Material: |

Neoprene Twin Sphere Rubber Tubing with 304 SS Flanges & Covers |

| Design |

Operating Temp: 225°F at 225 psig | 1-3/8″ – 1-3/4″ of Lateral Offset |

| Testing: |

Hydro-Tested | PMI on all Rubber Joint Root-Rings |

These neoprene expansion joints were custom-designed for water cooling loops at a chemical plant in Louisiana. They have a neoprene twin sphere rubber tubing with 304 stainless steel flanges and covers. U.S. Bellows fabricated five of each of the following dimensions: 3×10, 6×10, 8×12, and 10×14. They are designed for an operating temperature of 225°F at 225 psig and 1-3/8″ – 1-3/4″ of lateral offset. The units were hydro-tested and PMI on all rubber joint root-rings prior to shipment.

Besides chemical plants, other plants that utilize rubber expansion joints are air scrubber systems, sewage treatment, wastewater treatment, and water treatment plants. Combined cycle power plants also often utilize rubber spool-type expansion joints. No matter the application, our team of experienced engineers and designers can help to resolve your expansion joint needs. Please contact us via our 24×7 emergency service or send an email to info@pipingtech.com.

PT&P REF. ORIGINAL POST 06242020

| Type: |

Neoprene Expansion Joint |

| Size: |

3×10, 6×10, 8×12, 10×14 |

| Material: |

Neoprene Twin Sphere Rubber Tubing with 304 SS Flanges & Covers |

| Design |

Operating Temp: 225°F at 225 psig | 1-3/8″ – 1-3/4″ of Lateral Offset |

| Testing: |

Hydro-Tested | PMI on all Rubber Joint Root-Rings |

These neoprene expansion joints were custom-designed for water cooling loops at a chemical plant in Louisiana. They have a neoprene twin sphere rubber tubing with 304 stainless steel flanges and covers. U.S. Bellows fabricated five of each of the following dimensions: 3×10, 6×10, 8×12, and 10×14. They are designed for an operating temperature of 225°F at 225 psig and 1-3/8″ – 1-3/4″ of lateral offset. The units were hydro-tested and PMI on all rubber joint root-rings prior to shipment.

Besides chemical plants, other plants that utilize rubber expansion joints are air scrubber systems, sewage treatment, wastewater treatment, and water treatment plants. Combined cycle power plants also often utilize rubber spool-type expansion joints. No matter the application, our team of experienced engineers and designers can help to resolve your expansion joint needs. Please contact us via our 24×7 emergency service or send an email to info@pipingtech.com.

PT&P REF. ORIGINAL POST 06242020

Read More

| Type: |

Pressure Balanced Tee Expansion Joints |

| Size: |

352″ OAL | 81″ Dia. | 90″ Centerline to Bevel End |

| Material: |

304 Stainless Steel | CS |

| Design |

392°F at 15 psig | 6″ Axial Compression |

| Testing: |

100% Dye Penetrant | Air Soap and Bubble test |

U.S. Bellows custom designed pressure balanced tee expansion joints for a chemical plant in Texas. The units are 352″ overall length, 81″ diameter, and 90″ center line to the bevel-end of the tee. All assemblies were completely fabricated from 304 stainless steel. They are designed for an operating temperature of 392°F at 15 psig, with 6″ of axial compression and 1.25″ of lateral deflection. The expansion joints were 100% dye penetrate tested and air soap and bubble tested prior to shipment.

We can also design and manufacture refractory lined expansion joints for these types that are able to expand and contract as conditions move from hot to cold. These units can be installed in refineries, power plants, and various green energy facilities where no other option is practical. Our team of engineers and manufacturing staff are ready and willing to assist in helping solve any design and/or manufacturing challenges. We can also refurbish existing units to help decrease the time operations are shut down. We assure you that our 24×7 web-based emergency and quick-turn-around service can help when you need it most.

View Expansion Joint Product Section.

PT&P REF. ORIGINAL POST 04192019

| Type: |

Pressure Balanced Tee Expansion Joints |

| Size: |

352″ OAL | 81″ Dia. | 90″ Centerline to Bevel End |

| Material: |

304 Stainless Steel | CS |

| Design |

392°F at 15 psig | 6″ Axial Compression |

| Testing: |

100% Dye Penetrant | Air Soap and Bubble test |

U.S. Bellows custom designed pressure balanced tee expansion joints for a chemical plant in Texas. The units are 352″ overall length, 81″ diameter, and 90″ center line to the bevel-end of the tee. All assemblies were completely fabricated from 304 stainless steel. They are designed for an operating temperature of 392°F at 15 psig, with 6″ of axial compression and 1.25″ of lateral deflection. The expansion joints were 100% dye penetrate tested and air soap and bubble tested prior to shipment.

We can also design and manufacture refractory lined expansion joints for these types that are able to expand and contract as conditions move from hot to cold. These units can be installed in refineries, power plants, and various green energy facilities where no other option is practical. Our team of engineers and manufacturing staff are ready and willing to assist in helping solve any design and/or manufacturing challenges. We can also refurbish existing units to help decrease the time operations are shut down. We assure you that our 24×7 web-based emergency and quick-turn-around service can help when you need it most.

View Expansion Joint Product Section.

PT&P REF. ORIGINAL POST 04192019

Read More

| Type: |

Hinged Expansion Joints |

| Size: |

42″ Long | 16″ Nominal Pipe Size |

| Material: |

316L Stainless Steel | Carbon Steel |

| Design |

400°F at 150 psig | 4.25″ Lateral | 1° Angular |

| Testing: |

100% Dye Pen. | Bellows Longitudinal Seams

100% X-rayed | Hydro-Tested at 250 psig |

U.S. Bellows custom-designed hinged universal expansion joint for a steam exhaust application at a chemical plant in Texas for one of the largest cracker installations in the USA to support the manufacture of mainly olefins and polypropylene. The units are 42″ long and have a nominal pipe size of 16″. The bellows are fabricated from 316L stainless steel. The flanges, pipe spool, and hardware are carbon steel. They are designed for an operating temperature of 400°F at 150 psig. They are capable of 4.25″ lateral deflection and 1° of angular movement. The expansion joints were 100% dye penetrant tested, the bellows longitudinal seams were 100% X-rayed, and a hydro-test at 250 psig was performed prior to shipment.

PT&P REF. ORIGINAL POST 02112020

| Type: |

Hinged Expansion Joints |

| Size: |

42″ Long | 16″ Nominal Pipe Size |

| Material: |

316L Stainless Steel | Carbon Steel |

| Design |

400°F at 150 psig | 4.25″ Lateral | 1° Angular |

| Testing: |

100% Dye Pen. | Bellows Longitudinal Seams

100% X-rayed | Hydro-Tested at 250 psig |

U.S. Bellows custom-designed hinged universal expansion joint for a steam exhaust application at a chemical plant in Texas for one of the largest cracker installations in the USA to support the manufacture of mainly olefins and polypropylene. The units are 42″ long and have a nominal pipe size of 16″. The bellows are fabricated from 316L stainless steel. The flanges, pipe spool, and hardware are carbon steel. They are designed for an operating temperature of 400°F at 150 psig. They are capable of 4.25″ lateral deflection and 1° of angular movement. The expansion joints were 100% dye penetrant tested, the bellows longitudinal seams were 100% X-rayed, and a hydro-test at 250 psig was performed prior to shipment.

PT&P REF. ORIGINAL POST 02112020

Read More

| Type: |

Single Flanged Expansion Joint |

| Size: |

5″ Length | 6″ ID | 11″ O.D. |

| Material: |

ASTM A240-316 Stainless Steel |

| Design |

200°F | 150 psig | 7,942 lb/in. Lateral Spring Rate

0.625 ” Axial Travel | 803 lb/in. Axial Spring Rate

0.125″ Lateral Offset | 225 psig Test Pressure |

| Testing: |

100% Dye-Penetrant | Air, Soap, & Bubble |

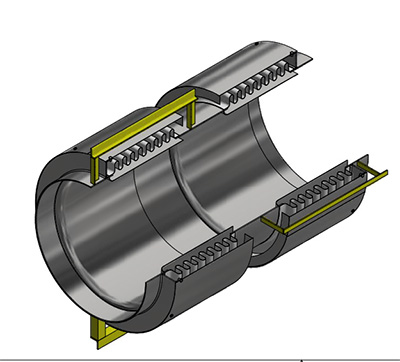

These units were sold to a company that manufactures customized power conversion solutions used in power supplies, transformers, inductors and capacitors for industrial and military applications. Expansion joints are used in a wide range of industries from automotive, food processing, biofuels, and wastewater treatment plants. This expansion joint is simply a bellows element with flanged end connections. Regardless of accessories, such as liners and covers, it will deflect in any direction or plane. It is the least expensive type of metal expansion joint but requires that the piping be controlled or guided as to the specified direction of the movements required. This type of expansion joint should not be expected to control the movement of the pipe. If the piping analysis shows that the expansion joint must accept axial compression, then the piping must be guided and constrained so that only that movement will occur. This expansion joint will not resist any deflection other than the resistance of the bellows, which is a function of the spring rate times the deflection amount. It is incapable of resisting the pressure thrust along its axis, which is the product of the pressure times the effective, or cross-sectional, area of the bellows. Large diameter units, even with low pressures, can generate very large axial pressure thrust forces, which must be contained by main and directional anchors. Otherwise, the expansion joint will exceed its designed function.

Piping Technology and its subsidiaries, in this case, US Bellows, prides itself on its long-standing relationships with ALL its customers. We have worked with this client for over 10 years with our first project in the early 2000s. We have been their vendor of choice for almost every expansion joint since then. We believe we must be strategic partners with our clients to understand their technical, delivery, and commercial needs to best move forward. This is where we are different than other key players as we have “in-house” technical and manufacturing expertise in our plant located in Houston, Texas to address customer queries or updates in real-time. An example of what our customers say:

“Thank you very much for the excellent work you and your associates at USB provided on my expansion joint order. Although we agreed to 10-day rush delivery, your shop responded to my project schedule and delivered 14 bellows assemblies in only 7 days from my order. This quick delivery helped us avert a scheduling conflict on a very critical project. I would be glad to recommend U.S. Bellows to anyone in need of a quality product with on-time or better delivery. 2022”

*Designed in accordance with the Standards of the Expansion Joint Manufacturers Association, 10th E, and welding per ASME Boiler and Pressure Vessel Code Section IX.

PT&P REF. ORIGINAL POST 08252020

| Type: |

Single Flanged Expansion Joint |

| Size: |

5″ Length | 6″ ID | 11″ O.D. |

| Material: |

ASTM A240-316 Stainless Steel |

| Design |

200°F | 150 psig | 7,942 lb/in. Lateral Spring Rate

0.625 ” Axial Travel | 803 lb/in. Axial Spring Rate

0.125″ Lateral Offset | 225 psig Test Pressure |

| Testing: |

100% Dye-Penetrant | Air, Soap, & Bubble |

These units were sold to a company that manufactures customized power conversion solutions used in power supplies, transformers, inductors and capacitors for industrial and military applications. Expansion joints are used in a wide range of industries from automotive, food processing, biofuels, and wastewater treatment plants. This expansion joint is simply a bellows element with flanged end connections. Regardless of accessories, such as liners and covers, it will deflect in any direction or plane. It is the least expensive type of metal expansion joint but requires that the piping be controlled or guided as to the specified direction of the movements required. This type of expansion joint should not be expected to control the movement of the pipe. If the piping analysis shows that the expansion joint must accept axial compression, then the piping must be guided and constrained so that only that movement will occur. This expansion joint will not resist any deflection other than the resistance of the bellows, which is a function of the spring rate times the deflection amount. It is incapable of resisting the pressure thrust along its axis, which is the product of the pressure times the effective, or cross-sectional, area of the bellows. Large diameter units, even with low pressures, can generate very large axial pressure thrust forces, which must be contained by main and directional anchors. Otherwise, the expansion joint will exceed its designed function.

Piping Technology and its subsidiaries, in this case, US Bellows, prides itself on its long-standing relationships with ALL its customers. We have worked with this client for over 10 years with our first project in the early 2000s. We have been their vendor of choice for almost every expansion joint since then. We believe we must be strategic partners with our clients to understand their technical, delivery, and commercial needs to best move forward. This is where we are different than other key players as we have “in-house” technical and manufacturing expertise in our plant located in Houston, Texas to address customer queries or updates in real-time. An example of what our customers say:

“Thank you very much for the excellent work you and your associates at USB provided on my expansion joint order. Although we agreed to 10-day rush delivery, your shop responded to my project schedule and delivered 14 bellows assemblies in only 7 days from my order. This quick delivery helped us avert a scheduling conflict on a very critical project. I would be glad to recommend U.S. Bellows to anyone in need of a quality product with on-time or better delivery. 2022”

*Designed in accordance with the Standards of the Expansion Joint Manufacturers Association, 10th E, and welding per ASME Boiler and Pressure Vessel Code Section IX.

PT&P REF. ORIGINAL POST 08252020

Read More

| Type: |

Hinged Expansion Joint |

| Size: |

66″ in diameter and 39-3/8″ OAL |

| Material: |

Incoloy 825 / 321 stainless steel |

| Design |

73 psig at 986°F with 4.25 degrees of angular rotation |

| Testing: |

Dye Penetrant, X-Ray, PMI, Hydrotest |

These single hinged expansion joints were custom designed by U.S. Bellows for a chemical plant in Saudi Arabia. The units are 66″ in diameter and 39-3/8″ OAL. The bellows are fabricated from Incoloy 825 with the weld ends, hinges, liner, and cover from 321 stainless steel. The expansion joints are designed for an operating pressure of 73 psig at 986°F with 4.25 degrees of angular rotation. All units were dye-penetrant tested, X-ray tested on all bellows and pipe longitudinal weld seams, PMI tested on all alloy components, and the alloy steel plate for the pipe was ultrasonic tested prior to shipment. Hinged Pipe Expansion Joints also contain hinges or pivots which allow the unit to bend in a single plane. We’ve supplied this type of expansion joint for both methanol and ammonia plants. They are also used in piping systems for Air, Steam, Gas Turbines, Reformer Ducts, and Burners. These units are designed to restrict axial deflection in extension or compression. The hinge mechanism is typically designed to accept full-pressure thrust. Also, because of the hinge mechanism’s design, shear loads, such as from the weight of adjacent piping, can be accepted by this pipe expansion joint, relieving the piping designer of having to provide additional supports and anchors required by the Single type.

PT&P REF. ORIGINAL POST 06182019

| Type: |

Hinged Expansion Joint |

| Size: |

66″ in diameter and 39-3/8″ OAL |

| Material: |

Incoloy 825 / 321 stainless steel |

| Design |

73 psig at 986°F with 4.25 degrees of angular rotation |

| Testing: |

Dye Penetrant, X-Ray, PMI, Hydrotest |

These single hinged expansion joints were custom designed by U.S. Bellows for a chemical plant in Saudi Arabia. The units are 66″ in diameter and 39-3/8″ OAL. The bellows are fabricated from Incoloy 825 with the weld ends, hinges, liner, and cover from 321 stainless steel. The expansion joints are designed for an operating pressure of 73 psig at 986°F with 4.25 degrees of angular rotation. All units were dye-penetrant tested, X-ray tested on all bellows and pipe longitudinal weld seams, PMI tested on all alloy components, and the alloy steel plate for the pipe was ultrasonic tested prior to shipment. Hinged Pipe Expansion Joints also contain hinges or pivots which allow the unit to bend in a single plane. We’ve supplied this type of expansion joint for both methanol and ammonia plants. They are also used in piping systems for Air, Steam, Gas Turbines, Reformer Ducts, and Burners. These units are designed to restrict axial deflection in extension or compression. The hinge mechanism is typically designed to accept full-pressure thrust. Also, because of the hinge mechanism’s design, shear loads, such as from the weight of adjacent piping, can be accepted by this pipe expansion joint, relieving the piping designer of having to provide additional supports and anchors required by the Single type.

PT&P REF. ORIGINAL POST 06182019

Read More

| Type: |

Tied Universal Elbow Expansion Joint |

| Size: |

20″ Dia. | 112″ Face-of-Flange to Center Line of Elbow OAL |

| Material: |

Inconel® 625 Bellows | 304 H Stainless Steel |

| Design |

Operating Temp: 1,150°F at 140 psig | 4″ Lateral Deflection |

| Testing: |

Dye Penetrant Examined | 100% X-Rayed Bellows | Hydro-tested |

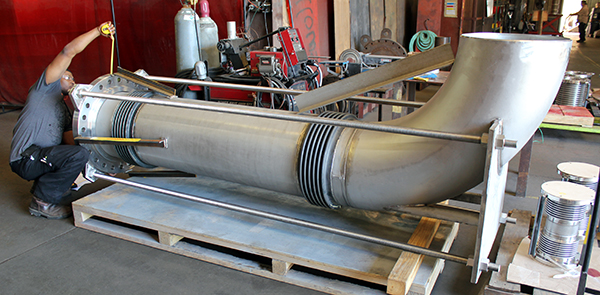

U.S. Bellows, Inc. custom-designed a tied universal elbow expansion joint for ammonia and waste processing for a nitrogen fertilizer plant. The bellows and liner are fabricated from Inconel® 625. The pipe, tie rods, and flanges are fabricated from 304 H stainless steel. It is designed for an operating temperature of 1,150°F at 140 psig and 4″ of lateral deflection. The assembly is 20″ in diameter and 112″ face-of-flange to the centerline of elbow OAL. The unit was 100% x-rayed, dye-penetrate examined, and hydro-tested before shipment.

| Type: |

Tied Universal Elbow Expansion Joint |

| Size: |

20″ Dia. | 112″ Face-of-Flange to Center Line of Elbow OAL |

| Material: |

Inconel® 625 Bellows | 304 H Stainless Steel |

| Design |

Operating Temp: 1,150°F at 140 psig | 4″ Lateral Deflection |

| Testing: |

Dye Penetrant Examined | 100% X-Rayed Bellows | Hydro-tested |

U.S. Bellows, Inc. custom-designed a tied universal elbow expansion joint for ammonia and waste processing for a nitrogen fertilizer plant. The bellows and liner are fabricated from Inconel® 625. The pipe, tie rods, and flanges are fabricated from 304 H stainless steel. It is designed for an operating temperature of 1,150°F at 140 psig and 4″ of lateral deflection. The assembly is 20″ in diameter and 112″ face-of-flange to the centerline of elbow OAL. The unit was 100% x-rayed, dye-penetrate examined, and hydro-tested before shipment.

Read More

U.S. Bellows designed universal expansion joints for a wastewater treatment plant in Florida. This was done for a longtime client and market leader in wastewater management, energy services, water, and wastewater treatment. The units are 60″ tall and have a 26.75″ inside diameter. The bellows, cover, liner, and weld-ends are fabricated from 304 stainless steel. They are designed for an operating temperature of 1000°F at 11 psig, with 2″ axial compression and lateral deflection. The units were pneumatically tested at 12 psig prior to shipment. The on-site inspection was done by the client and the EPC firm at our manufacturing facility with our Engineers present to provide any additional clarity that was needed.

U.S. Bellows, EJMA member, is a leader in bellows design and manufacturing. With our manufacturing and engineering both in Houston, we have over 45 years of experience and have deployed over 250k expansion joints which does not include maintenance and repairs services conducted by our highly qualified field service team.

Custom expansion joint design and manufacturing is a complex process and we execute it effectively by focusing on the approval drawings from the customer side, training on customer support with all functional teams (production, engineering, shipping, and sales), and inter-team communication. We developed and deployed digital work instructions for all key production steps and added detailing and reviewing checklists of all of the expansion joint drawings before releasing them to fabrication. These improvements have reduced considerably the number of revisions and reworks. Some insight into jobs we have conducted successfully include:

- Refurbished 6 48″-64″ Refractory-lined Expansion Joints for a Large Houston Refinery during a 45-day turnaround

- Completed a large ducting project for a Major Chemical facility in Texas with on-time delivery

- In the last 6 months, 40% of our expansion joint jobs have shipped in 2 weeks

PT&P REF. ORIGINAL POST 11122018

U.S. Bellows designed universal expansion joints for a wastewater treatment plant in Florida. This was done for a longtime client and market leader in wastewater management, energy services, water, and wastewater treatment. The units are 60″ tall and have a 26.75″ inside diameter. The bellows, cover, liner, and weld-ends are fabricated from 304 stainless steel. They are designed for an operating temperature of 1000°F at 11 psig, with 2″ axial compression and lateral deflection. The units were pneumatically tested at 12 psig prior to shipment. The on-site inspection was done by the client and the EPC firm at our manufacturing facility with our Engineers present to provide any additional clarity that was needed.

U.S. Bellows, EJMA member, is a leader in bellows design and manufacturing. With our manufacturing and engineering both in Houston, we have over 45 years of experience and have deployed over 250k expansion joints which does not include maintenance and repairs services conducted by our highly qualified field service team.

Custom expansion joint design and manufacturing is a complex process and we execute it effectively by focusing on the approval drawings from the customer side, training on customer support with all functional teams (production, engineering, shipping, and sales), and inter-team communication. We developed and deployed digital work instructions for all key production steps and added detailing and reviewing checklists of all of the expansion joint drawings before releasing them to fabrication. These improvements have reduced considerably the number of revisions and reworks. Some insight into jobs we have conducted successfully include:

- Refurbished 6 48″-64″ Refractory-lined Expansion Joints for a Large Houston Refinery during a 45-day turnaround

- Completed a large ducting project for a Major Chemical facility in Texas with on-time delivery

- In the last 6 months, 40% of our expansion joint jobs have shipped in 2 weeks

PT&P REF. ORIGINAL POST 11122018

Read More

U.S. Bellows, Inc. provided rubber expansion joints for an 8″ pipeline. This single open arch rubber expansion joint is fabricated from EPDM rubber and the retaining rings are galvanized A36 carbon steel and powder coated orange. The expansion joints were designed for an operating pressure of 250 psig with a 30″ vacuum, 1.75″ compression, 0.88″ extension, and 1″ lateral offset. Rubber pipe expansion joints are often used to compensate for minor misalignment and offset. Each unit was hydro-tested at 250°F at 75 psig. An advantage of a rubber expansion joint (also called an elastomer joint) over the metallic is the ability to prevent the transmission of vibration and to do this without significant harm to the joint. They can be utilized for pump inlets and discharges solely to stop vibration and noise from the pump. They have an integrally flanged design where no gaskets are required. Metal reinforcing rings can also be added to help resist pressure and flexing during operation. Fabric reinforcement within the rubber can also be added for applications to take the load of fluid pressure. At U.S. Bellows, our engineers are professionally trained and qualified to both design and manufacture units specifically for your application per expansion joint manufacturing association (EJMA).

U.S. Bellows, Inc. provided rubber expansion joints for an 8″ pipeline. This single open arch rubber expansion joint is fabricated from EPDM rubber and the retaining rings are galvanized A36 carbon steel and powder coated orange. The expansion joints were designed for an operating pressure of 250 psig with a 30″ vacuum, 1.75″ compression, 0.88″ extension, and 1″ lateral offset. Rubber pipe expansion joints are often used to compensate for minor misalignment and offset. Each unit was hydro-tested at 250°F at 75 psig. An advantage of a rubber expansion joint (also called an elastomer joint) over the metallic is the ability to prevent the transmission of vibration and to do this without significant harm to the joint. They can be utilized for pump inlets and discharges solely to stop vibration and noise from the pump. They have an integrally flanged design where no gaskets are required. Metal reinforcing rings can also be added to help resist pressure and flexing during operation. Fabric reinforcement within the rubber can also be added for applications to take the load of fluid pressure. At U.S. Bellows, our engineers are professionally trained and qualified to both design and manufacture units specifically for your application per expansion joint manufacturing association (EJMA).

Read More

U.S. Bellows designed this thick wall flanged and flued head expansion joint at a sulfuric acid plant in Louisiana. Sulfuric acid plants are located throughout the industrialized world and we have worked with most of them including market leaders. Most are located near their product acid’s point of use, i.e., near fertilizer plants, copper ore leach plants, and petroleum refineries. This is because elemental sulfur is cheaper to transport than sulfuric acid. By far the largest amount of sulfuric acid is used to make phosphoric acid, used, in turn, to make the phosphate fertilizers, calcium dihydrogenphosphate, and ammonium phosphates. It is also used to make ammonium sulfate, which is a particularly important fertilizer in sulfur-deficient. In various concentrations, the acid is used in the manufacture of fertilizers, pigments, dyes, drugs, explosives, detergents, and inorganic salts and acids, as well as in petroleum refining and metallurgical processes.

The expansion joint was fabricated from A516-70 carbon steel and painted with a special epoxy coat for protection from corrosion. The unit is 96″ x 124-1/4″ O.D. All of the butt welds for this expansion joint were 100% liquid penetrant, 100% radiographic, and soap and air bubble tested prior to shipment. This type of joint can be used as a “clamshell” joint used in conjunction with shell and tube heat exchangers, steam exhaust, hot water return lines, or chilled water lines.

U.S. Bellows designed this thick wall flanged and flued head expansion joint at a sulfuric acid plant in Louisiana. Sulfuric acid plants are located throughout the industrialized world and we have worked with most of them including market leaders. Most are located near their product acid’s point of use, i.e., near fertilizer plants, copper ore leach plants, and petroleum refineries. This is because elemental sulfur is cheaper to transport than sulfuric acid. By far the largest amount of sulfuric acid is used to make phosphoric acid, used, in turn, to make the phosphate fertilizers, calcium dihydrogenphosphate, and ammonium phosphates. It is also used to make ammonium sulfate, which is a particularly important fertilizer in sulfur-deficient. In various concentrations, the acid is used in the manufacture of fertilizers, pigments, dyes, drugs, explosives, detergents, and inorganic salts and acids, as well as in petroleum refining and metallurgical processes.

The expansion joint was fabricated from A516-70 carbon steel and painted with a special epoxy coat for protection from corrosion. The unit is 96″ x 124-1/4″ O.D. All of the butt welds for this expansion joint were 100% liquid penetrant, 100% radiographic, and soap and air bubble tested prior to shipment. This type of joint can be used as a “clamshell” joint used in conjunction with shell and tube heat exchangers, steam exhaust, hot water return lines, or chilled water lines.

Read More

U.S. Bellows, Inc. designed and fabricated this rectangular fabric expansion joint for a heat recovery system at a cement plant in Indiana. The unit was fabricated with a high-temperature PTFE fabric belt and carbon steel frame. The dimensions are 197″ in length, 118″ in width, and 18″ face-to-face. The expansion joint is designed for an operating temperature of -20°-400°F at +/- 60″ water column and 1″ of axial compression and lateral offset. A dye-penetrant exam was performed on all welds before shipment.

Fabric expansion joints are often used in ducts that carry hot gases at low pressures. The major design parameters are the temperatures and flow rates of the gases and the amount and abrasiveness of solids suspended in the gases. Rectangular fabric expansion joints are also used in power plant ducting that requires joints from the boiler or economizer outlet to the chimney.

Also, they can be used on ducting to the coal pulverizers and the furnace-air inlets. Combustion turbines will also use these types of joints in exhaust and heat-recovery ducts. The primary duct movement this type of joint absorbs is axial expansion and contraction due to temperature changes. The expansion joint designer can also design for lateral and angular movements. Elastomers and Plastomers are the basic flexible materials used to construct the belting material for these joints. These sheets can be used in combination with woven glass, metal wire, fluoroelastomers, insulation, and other materials for use in applications where there may be abrasive material, condensate, acids, and other particles that could reduce the expected life of the joint. Our experienced engineers are also skilled in the various methods and fasteners to connect the belting material to the metal frames of the expansion joint.

This expansion joint was designed for a cement plant for one of the largest building material manufacturers worldwide. Such facilities make products ranging from fly ash, slag, masonry, white, specialty and oil well cements for use in commercial construction, residential construction, and industrial applications.

USB REF. ORIGINAL POST 03132017

U.S. Bellows, Inc. designed and fabricated this rectangular fabric expansion joint for a heat recovery system at a cement plant in Indiana. The unit was fabricated with a high-temperature PTFE fabric belt and carbon steel frame. The dimensions are 197″ in length, 118″ in width, and 18″ face-to-face. The expansion joint is designed for an operating temperature of -20°-400°F at +/- 60″ water column and 1″ of axial compression and lateral offset. A dye-penetrant exam was performed on all welds before shipment.

Fabric expansion joints are often used in ducts that carry hot gases at low pressures. The major design parameters are the temperatures and flow rates of the gases and the amount and abrasiveness of solids suspended in the gases. Rectangular fabric expansion joints are also used in power plant ducting that requires joints from the boiler or economizer outlet to the chimney.

Also, they can be used on ducting to the coal pulverizers and the furnace-air inlets. Combustion turbines will also use these types of joints in exhaust and heat-recovery ducts. The primary duct movement this type of joint absorbs is axial expansion and contraction due to temperature changes. The expansion joint designer can also design for lateral and angular movements. Elastomers and Plastomers are the basic flexible materials used to construct the belting material for these joints. These sheets can be used in combination with woven glass, metal wire, fluoroelastomers, insulation, and other materials for use in applications where there may be abrasive material, condensate, acids, and other particles that could reduce the expected life of the joint. Our experienced engineers are also skilled in the various methods and fasteners to connect the belting material to the metal frames of the expansion joint.

This expansion joint was designed for a cement plant for one of the largest building material manufacturers worldwide. Such facilities make products ranging from fly ash, slag, masonry, white, specialty and oil well cements for use in commercial construction, residential construction, and industrial applications.

USB REF. ORIGINAL POST 03132017

Read More