U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., specially designed and manufactured fabric expansion joints reaching sizes up to 32′ x 12′ for a power station in New York. The largest of the expansion joints that are to support the air ducts of the power station, was designed at 32′ x 12′, while the others measured at 10′ x 12′. The expansion joints were fabricated with high-temperature fabric belts and 4″ thick insulation pillows. The designing conditions were at 30″ WC and 950°F.

Tag: Blog

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., specially designed and manufactured fabric expansion joints reaching sizes up to 32′ x 12′ for a power station in New York. The largest of the expansion joints that are to support the air ducts of the power station, was designed at 32′ x 12′, while the others measured at 10′ x 12′. The expansion joints were fabricated with high-temperature fabric belts and 4″ thick insulation pillows. The designing conditions were at 30″ WC and 950°F.

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., specially designed and fabricated a 12′ x 30′ x 12″ face to face, high temperature, fabric expansion joint. The expansion joint was fabricated with a 3-layered fabric belt, A516 Gr. 70 telescoping liners / frame, and insulation pillows. It was designed at 650°F and 30″ WC for 1/2″ compression and 1/4″ lateral. This expansion joint will be installed in an exhaust system at a power plant in New York. EJMA standards, Fluid Sealing Association standards, and B31.3 code were used in the design and fabrication of these joints.

12′ x 30′ x 12″ Face to Face, High Temperature, Fabric Expansion Joint for a Power Plant in New York

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., specially designed and fabricated a 12′ x 30′ x 12″ face to face, high temperature, fabric expansion joint. The expansion joint was fabricated with a 3-layered fabric belt, A516 Gr. 70 telescoping liners / frame, and insulation pillows. It was designed at 650°F and 30″ WC for 1/2″ compression and 1/4″ lateral. This expansion joint will be installed in an exhaust system at a power plant in New York. EJMA standards, Fluid Sealing Association standards, and B31.3 code were used in the design and fabrication of these joints.

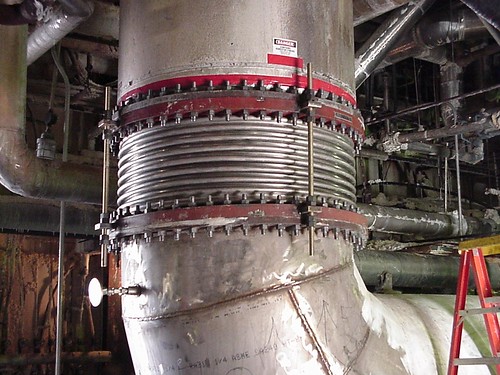

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., specially designed and fabricated a 54″ diameter tied, universal expansion joint for NASA Space Center. The expansion joints were designed at full vacuum and 450° F and constructed with 304 SS bellows, liner and A516 Gr. 70 spool, weld ends and carbon steel tie rods. The bellows’ attachment welds were 100% dye-penetrant tested.

54″ Diameter Tied Universal Expansion Joint for NASA Space Center

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., specially designed and fabricated a 54″ diameter tied, universal expansion joint for NASA Space Center. The expansion joints were designed at full vacuum and 450° F and constructed with 304 SS bellows, liner and A516 Gr. 70 spool, weld ends and carbon steel tie rods. The bellows’ attachment welds were 100% dye-penetrant tested.

Read MoreThree-day Emergency Fabrication of a 40″ I.D., Clamshell Expansion Joint for a Chemical Plant in Texas

Within a three day span, U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., fabricated a 40 I.D., single coded, clamshell expansion joint for a chemical plant in Beaumont, Texas. The chemical company utilized U.S. Bellows’ 24 x 7 Quick Turn/Emergency service.

After the representative from the chemical plant completed the online form, the U.S Bellows’ on-call team was immediately paged. Three days later the bellow had been successfully fabricated, welded to an A516-70 heat exchanger shell and shipped to the chemical plant to resume operation. The bellow was fabricated from A240 tp 321SS and designed at 50 PSIG and 750oF. In order to detect any leaks in the weld, the bellow’s long seam weld was 100% x-rayed and its attachment weld was 100% dye-penetrant.

Three-day Emergency Fabrication of a 40″ I.D., Clamshell Expansion Joint for a Chemical Plant in Texas

Three-day Emergency Fabrication of a 40″ I.D., Clamshell Expansion Joint for a Chemical Plant in Texas

Within a three day span, U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., fabricated a 40 I.D., single coded, clamshell expansion joint for a chemical plant in Beaumont, Texas. The chemical company utilized U.S. Bellows’ 24 x 7 Quick Turn/Emergency service.

After the representative from the chemical plant completed the online form, the U.S Bellows’ on-call team was immediately paged. Three days later the bellow had been successfully fabricated, welded to an A516-70 heat exchanger shell and shipped to the chemical plant to resume operation. The bellow was fabricated from A240 tp 321SS and designed at 50 PSIG and 750oF. In order to detect any leaks in the weld, the bellow’s long seam weld was 100% x-rayed and its attachment weld was 100% dye-penetrant.

Read MoreU.S. Bellows/PT&P specially designed and fabricated 40 externally pressurized expansion joints for the piping system of a steam plant in Kent, Ohio. The sizes of the expansion joints ranged from 10 to 24. The expansion joints were designed at 150 psig and 350 °F for a maximum of 4 compressions and fabricated with 304 SS bellows and carbon steel shell and flanges. The joints were leak tested before shipment.

Externally pressurized expansion joints for steam plant in Kent, Ohio

U.S. Bellows/PT&P specially designed and fabricated 40 externally pressurized expansion joints for the piping system of a steam plant in Kent, Ohio. The sizes of the expansion joints ranged from 10 to 24. The expansion joints were designed at 150 psig and 350 °F for a maximum of 4 compressions and fabricated with 304 SS bellows and carbon steel shell and flanges. The joints were leak tested before shipment.

Read MoreUS Bellows, the expansion joint division of Piping Technology & Products, designed and fabricated a 71″ x 143″ rectangular expansion joint for an oil refinery in India. The expansion joint was fabricated from SS 316 L, designed at 18 PSIG at 417°F. It is equipped with a liner and a rounded corner bellows design. EJMA Standards and B31.3 code were used in the design and fabrication of this joint.

71″x143″ Rectangular Expansion Joint for an Oil Refinery in India

US Bellows, the expansion joint division of Piping Technology & Products, designed and fabricated a 71″ x 143″ rectangular expansion joint for an oil refinery in India. The expansion joint was fabricated from SS 316 L, designed at 18 PSIG at 417°F. It is equipped with a liner and a rounded corner bellows design. EJMA Standards and B31.3 code were used in the design and fabrication of this joint.

Read MoreU.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., fabricated 28-inch and 32-inch O.D Tied universal expansion joints for an oil refinery in China. The expansion joints were fabricated from 321 SS bellows, A105, 150#, RFSO. EJMA Standards and B31.3 code were used in the design and fabrication of these joints.

28″ and 32″ Tied Universal Expansion Joints for an Oil Refinery in China

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., fabricated 28-inch and 32-inch O.D Tied universal expansion joints for an oil refinery in China. The expansion joints were fabricated from 321 SS bellows, A105, 150#, RFSO. EJMA Standards and B31.3 code were used in the design and fabrication of these joints.

Read MoreU.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., specially designed and fabricated a 44-inch, O.D Universal, refractory lined expansion joint for a chemical plant in Venezuela.>The expansion joint was designed for 100 psig at 1,000° F and fabricated with 321 SS two-ply tested bellows, A-387 GR11 weld ends, 14 Ga. 304 SS, Hexmesh anchoring system and Resco 17 EMC refractory. The expansion joint was also designed and fabricated per B31.3 and EJMA Standards.

44″ Universal Refractory Lined Expansion Joint For A Chemical Plant In Venezuela

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., specially designed and fabricated a 44-inch, O.D Universal, refractory lined expansion joint for a chemical plant in Venezuela.>The expansion joint was designed for 100 psig at 1,000° F and fabricated with 321 SS two-ply tested bellows, A-387 GR11 weld ends, 14 Ga. 304 SS, Hexmesh anchoring system and Resco 17 EMC refractory. The expansion joint was also designed and fabricated per B31.3 and EJMA Standards.

Read More

The photograph above shows rectangular expansion joints being prepared for shipment to Russia. These were fabricated to replace units in a methanol plant duct system. The fabric belt is constructed of layers of material selected to handle the hot gases at low pressures. The frames can be fabricated from a variety of metals in a variety of shapes depending on the particular application.

Replacement Fabric Expansion Joint for Methanol Plant in Russia

The photograph above shows rectangular expansion joints being prepared for shipment to Russia. These were fabricated to replace units in a methanol plant duct system. The fabric belt is constructed of layers of material selected to handle the hot gases at low pressures. The frames can be fabricated from a variety of metals in a variety of shapes depending on the particular application.

U.S. Bellows, Inc. manufactures a stainless steel rectangular expansion joint, 28” x 66”, for an exhaust system at a chemical plant in South Carolina. This joint is equipped with a liner, tie rods system and mitered corner bellows design. The expansion joint was designed for 15 psig at 600°F and leak tested. A 100% dye-penetrant test was also performed on all the welds.

28″x 66″ Rectangular Expansion Joint For Chemical Plant In South Carolina

U.S. Bellows, Inc. manufactures a stainless steel rectangular expansion joint, 28” x 66”, for an exhaust system at a chemical plant in South Carolina. This joint is equipped with a liner, tie rods system and mitered corner bellows design. The expansion joint was designed for 15 psig at 600°F and leak tested. A 100% dye-penetrant test was also performed on all the welds.

Read More

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., designed and fabricated two 48-inch, triple-layered fabric expansion joints for a power plant in Columbia to be used in its exhaust system. The expansion joints were fabricated with three layers: outer, center and inner. The outer layers consisted of PTFE, 25% glass filled, coated fiberglass, center layers of ceramic fiberglass and the inner layers of aluminum-coated fiberglass. These expansion joints were designed at a pressure of 27” of WC and a temperature of 700°F.

48″ Triple Layered Fabric Expansion Joints

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., designed and fabricated two 48-inch, triple-layered fabric expansion joints for a power plant in Columbia to be used in its exhaust system. The expansion joints were fabricated with three layers: outer, center and inner. The outer layers consisted of PTFE, 25% glass filled, coated fiberglass, center layers of ceramic fiberglass and the inner layers of aluminum-coated fiberglass. These expansion joints were designed at a pressure of 27” of WC and a temperature of 700°F.

The photograph above shows a 72-inch universal pressure balanced expansion joint designed for a chemical plant in Pasadena, Texas. The expansion joint is designed for 30 psig at 200°F and full vacuum. All materials in the “wetted surface” are TP-316/316L stainless steel. Design movements are 3-inch axial compression and 5 ¾ -inch lateral offset. The assembly is approximately 24-feet long and 14,150 lbs.

72″ Universal Pressure Balanced Expansion Joint

The photograph above shows a 72-inch universal pressure balanced expansion joint designed for a chemical plant in Pasadena, Texas. The expansion joint is designed for 30 psig at 200°F and full vacuum. All materials in the “wetted surface” are TP-316/316L stainless steel. Design movements are 3-inch axial compression and 5 ¾ -inch lateral offset. The assembly is approximately 24-feet long and 14,150 lbs.

Read MoreU.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., designed and manufactured 16-inch and 30-inch elbow tied universal expansion joints, for a power station in Florida. These expansion joints, which are used to transport hot steam, are designed at 150 psig and 350° F. The bellows material is fabricated from Inco 625 and elbows and spool from carbon steel.

Elbow Tied Universal Expansion Joints for a Power Station in Florida

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., designed and manufactured 16-inch and 30-inch elbow tied universal expansion joints, for a power station in Florida. These expansion joints, which are used to transport hot steam, are designed at 150 psig and 350° F. The bellows material is fabricated from Inco 625 and elbows and spool from carbon steel.

Read MoreSweco Fab, a division of Piping Technology & Products, Inc., fabricated a 48-inch diameter thick-wall expansion joint for a refinery in Louisiana. The joint was fabricated from carbon steel with a 1/8″ minimum thickness. It is designed for an axial force of 2,500 lbs/in with a 1.15-inch axial deflection and a lateral force of 30,000 lbs./in. with a 0.002-inch lateral deflection.

48″ Diameter, Thick-Wall Expansion Joint for a refinery in Louisiana

Sweco Fab, a division of Piping Technology & Products, Inc., fabricated a 48-inch diameter thick-wall expansion joint for a refinery in Louisiana. The joint was fabricated from carbon steel with a 1/8″ minimum thickness. It is designed for an axial force of 2,500 lbs/in with a 1.15-inch axial deflection and a lateral force of 30,000 lbs./in. with a 0.002-inch lateral deflection.

Read More47 ¼” I.D. Universal Expansion Joint With SB-443 Round Corners Bellows

This picture shows a 47.25″ I.D. Universal Expansion Joint with SB-443 (Inco. 625) round corners bellows, and SA516-70 flanges for ethylene plant in Saudi Arabia. This expansion joint was custom designed and fabricated by U.S Bellows, Inc for an ethylene plant in Saudi Arabia.

47 1/4″ I.D. Universal Expansion Joint With SB-443 Round Corners Bellows

47 ¼” I.D. Universal Expansion Joint With SB-443 Round Corners Bellows

This picture shows a 47.25″ I.D. Universal Expansion Joint with SB-443 (Inco. 625) round corners bellows, and SA516-70 flanges for ethylene plant in Saudi Arabia. This expansion joint was custom designed and fabricated by U.S Bellows, Inc for an ethylene plant in Saudi Arabia.

Read MoreThe toroidal shape gives the bellow the unique ability to carry high pressures; conversely, it also permits modest deflection ability. The expansion joint was designed for 400 PSIG at 500° F and an extension stroke of 5/16″ and the bellow’s element was fabricated from .060″ Inconel® 600 with A-516 gr 70 weld ends. The 92-inch toroidal expansion joint was also designed per ASME Sec. VIII rules as well as the Expansion Joint Manufacturer EJMA Standards. Upon fabrication completion, a hydro test was conducted at 600 PSIG to detect leaks.

92″ I.D. Toroidal Bellow Expansion Joint for an ASME “U” Stamp Heat Exchanger Shell

The toroidal shape gives the bellow the unique ability to carry high pressures; conversely, it also permits modest deflection ability. The expansion joint was designed for 400 PSIG at 500° F and an extension stroke of 5/16″ and the bellow’s element was fabricated from .060″ Inconel® 600 with A-516 gr 70 weld ends. The 92-inch toroidal expansion joint was also designed per ASME Sec. VIII rules as well as the Expansion Joint Manufacturer EJMA Standards. Upon fabrication completion, a hydro test was conducted at 600 PSIG to detect leaks.

Read MoreU.S Bellows, Inc. manufactures 96, 3″ NPS tied universal bellows for a power plant located in Saudi Arabia. The bellows’ element is a unique design containing integral equalizing rings between the corrugations that provide excellent pressure resistance, as well as, anti-squirm resistance. The tear drop shape of the rings add little resistance to movement and cycle life is not compromised. Pressure design is based on 252 psi at 689° F with a lateral movement of 1.0″.

3″ NPS Tied Universal Bellows For A Power Plant in Saudi Arabia

U.S Bellows, Inc. manufactures 96, 3″ NPS tied universal bellows for a power plant located in Saudi Arabia. The bellows’ element is a unique design containing integral equalizing rings between the corrugations that provide excellent pressure resistance, as well as, anti-squirm resistance. The tear drop shape of the rings add little resistance to movement and cycle life is not compromised. Pressure design is based on 252 psi at 689° F with a lateral movement of 1.0″.

Read MoreU.S Bellows, Inc. manufactured 10″ single tied titanium expansion joints to be utilized in a chemical plant in Kingsport, Tennessee. These single expansion joints are bellows elements with end connections that allow movement in any direction or plane. However, the piping must also be guided in the same direction of the movement. The tie rods restrain the full pressure thrust. These expansion joints were 100% dye-penetrant examined before being shipped to the customer

10″ Single Tied Titanium Expansion Joints

U.S Bellows, Inc. manufactured 10″ single tied titanium expansion joints to be utilized in a chemical plant in Kingsport, Tennessee. These single expansion joints are bellows elements with end connections that allow movement in any direction or plane. However, the piping must also be guided in the same direction of the movement. The tie rods restrain the full pressure thrust. These expansion joints were 100% dye-penetrant examined before being shipped to the customer

Read More

The photograph above shows a rectangular fabric expansion joint in the final stages of assembly. The fabric “belt” is being attached to the metal frames. These expansion joints are inserted in metal ducts that carry hot gases at low pressures. Layers of different materials are selected to make a “belt” which will function at the high temperatures required.

Rectangular Fabric Expansion Joint

The photograph above shows a rectangular fabric expansion joint in the final stages of assembly. The fabric “belt” is being attached to the metal frames. These expansion joints are inserted in metal ducts that carry hot gases at low pressures. Layers of different materials are selected to make a “belt” which will function at the high temperatures required.

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc. rushed to an emergency call of an Alaskan petroleum firm. The firm called upon U.S. Bellows’ 24 x 7 Quick-Turn/Emergency service to aid them in the immediate replacement of a defective, 48″ diameter expansion joint when their G417 Pump failed suddenly during the plant startup.

The timeline of events demonstrates the quick engineering and manufacturing response from U.S Bellows:

07/21/00 (Friday) 5:30 p.m., U.S. Bellows receives an emergency call.

07/22/00 (Saturday) U.S. Bellows/ PT&P builds the 48″ diameter expansion joint and ships it to a location on the same day.

07/23/00 (Sunday) The 48″ diameter expansion joint designed and built by U.S. Bellows/PT&P was installed at a customer’s location.

The customer expressed great appreciation for the extraordinary efforts put forth by the individuals at U.S. Bellows. The on-call engineering and manufacturing team demonstrated its ability and commitment to servicing customers on an emergency basis.

U.S. Bellows is available on a 24 x 7 basis to fulfill any emergency requirements that might arise in the course of plant shut-downs or start-ups. The company has a system of stock bellows which can be used to assemble and ship different types of expansion joints including universal, elbow pressure balanced, and in-line pressure balanced expansion joints. The U.S. Bellows’ “on-call” engineering and manufacturing team is specifically equipped to handle rush and emergency orders. Using the unique web and Internet-based technology, the company is able to respond to any emergency requirements within 30 minutes of notification.

U.S. Bellows Responds to Emergency Order for a 48″ Diameter Expansion Joint

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc. rushed to an emergency call of an Alaskan petroleum firm. The firm called upon U.S. Bellows’ 24 x 7 Quick-Turn/Emergency service to aid them in the immediate replacement of a defective, 48″ diameter expansion joint when their G417 Pump failed suddenly during the plant startup.

The timeline of events demonstrates the quick engineering and manufacturing response from U.S Bellows:

07/21/00 (Friday) 5:30 p.m., U.S. Bellows receives an emergency call.

07/22/00 (Saturday) U.S. Bellows/ PT&P builds the 48″ diameter expansion joint and ships it to a location on the same day.

07/23/00 (Sunday) The 48″ diameter expansion joint designed and built by U.S. Bellows/PT&P was installed at a customer’s location.

The customer expressed great appreciation for the extraordinary efforts put forth by the individuals at U.S. Bellows. The on-call engineering and manufacturing team demonstrated its ability and commitment to servicing customers on an emergency basis.

U.S. Bellows is available on a 24 x 7 basis to fulfill any emergency requirements that might arise in the course of plant shut-downs or start-ups. The company has a system of stock bellows which can be used to assemble and ship different types of expansion joints including universal, elbow pressure balanced, and in-line pressure balanced expansion joints. The U.S. Bellows’ “on-call” engineering and manufacturing team is specifically equipped to handle rush and emergency orders. Using the unique web and Internet-based technology, the company is able to respond to any emergency requirements within 30 minutes of notification.

Read More