| Type: |

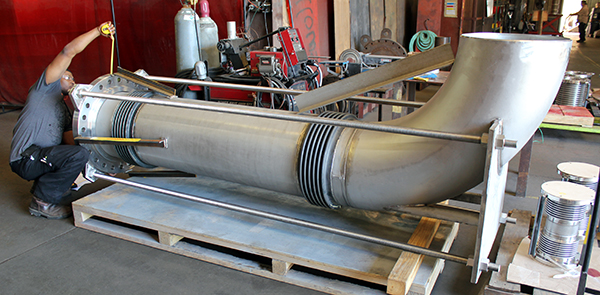

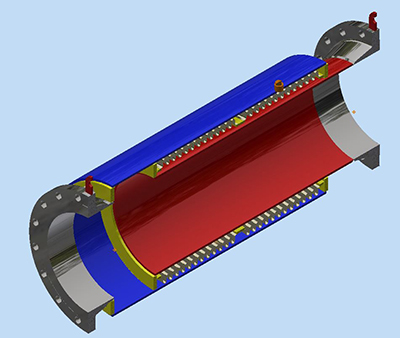

Universal Expansion Joints with Ductwork |

| Size: |

322″ Centerline-to-Centerline | 48″ Diameter |

| Material: |

304 Stainless Steel | Carbon Steel |

| Design |

400°F Operating Temp. @ 91 psig | 3.3″ Lateral |

| Testing: |

100% Dye-Penetrant | PMI | Hydro-tested |

U.S. Bellows custom designed this 26 ft. -10 in. long universal expansion joint with ductwork for a chemical plant. The bellows, ductwork, and flanges were fabricated from 304 stainless steel and the rest of the components from carbon steel. The unit is designed for 48″ diameter piping with an operating temperature of 400°F at 91 psig and 3.3″ of lateral deflection. The expansion joint was completed in 12 weeks and was 100% dye-penetrant, PMI, and hydro-tested before shipment. Chemical plants for which these are typically required process chemicals such as ethylene oxide/glycols, toluene diisocyanate, methylene diphenyl isocyanate, hydrochloric acid, polyether polyols, butanediol, GBL, n-methyl pyrrolidone, tetrahydrofuran, 2-pyrrolidone, PVP/PVPi, specialty amines, aniline, acetylene, surfactants, polytetrahydrofuran, and methylamines. The end products include furniture, automotive antifreeze, foams, carpets, construction, steel pickling, oil well acidizing, biodegradable plastics, lithium-ion battery production, pharmaceuticals, agriculture, gas treatment, water treatment, toothpaste, detergent, spandex fibers, engineered high-performance plastics, and animal feed.

U.S. Bellows has the scale and manufacturing agility to produce expansion joints and ductwork ranging in order size from a small scale of sub-1000 of dollars to upwards of 1M dollar large capital projects. We regularly support overnight lead times and tight project deliverables with evolving project requirements per the client and site needs. Last month, over half of our production capacity, was dedicated to this kind of work. A glimpse into our capabilities is outlined below from some projects we did last year:

– Refurbished 6, 48″-64″ diameter refractory-lined expansion joints for a large Houston refinery during a 45-day turnaround

– Completed a large ducting project for a major chemical facility in Texas with on-time delivery

– In the last 6 months, 40% of our expansion joint jobs have shipped in 2 weeks

We invite you to visit our facility and meet our team to get a first-hand look at our capabilities for your upcoming projects.

US-B REF. ORIGINAL POST 11122019

Read More

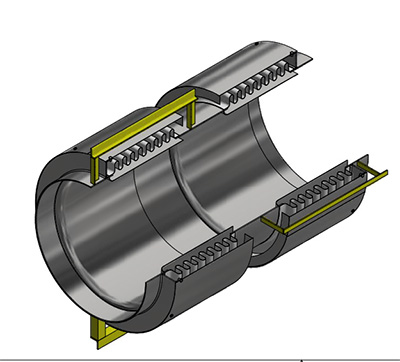

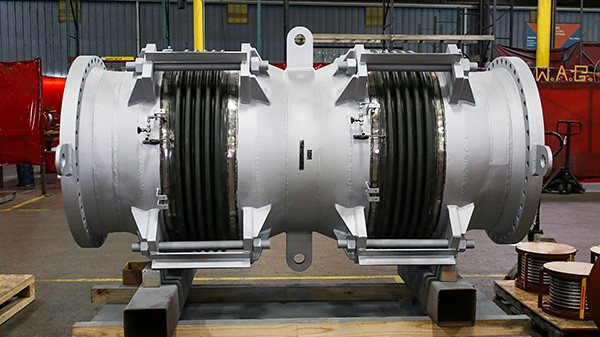

Externally pressurized pipe expansion joints, also known as X-Flex expansion joints, are suited for piping systems that require large amounts of axial compression or extension. In externally pressurized pipe expansion joints, the bellows elements are arranged so that the media flow is on the external surface of the bellows. Externally pressurizing the bellows eliminates pressure instability as a limitation to the design and permits the absorption of large amounts of axial expansion. Our QC department conducted various NDT examinations (X-Rays, PMI, Penetrant Tests, and Hydro Tests). Also provided were “weld maps” and MTR’s for client review and inspection. At U.S. Bellows, we are constantly developing and assisting client engineers in this effort toward decarbonation by designing innovative products to accommodate new and unusual design specifications.

Externally pressurized pipe expansion joints, also known as X-Flex expansion joints, are suited for piping systems that require large amounts of axial compression or extension. In externally pressurized pipe expansion joints, the bellows elements are arranged so that the media flow is on the external surface of the bellows. Externally pressurizing the bellows eliminates pressure instability as a limitation to the design and permits the absorption of large amounts of axial expansion. Our QC department conducted various NDT examinations (X-Rays, PMI, Penetrant Tests, and Hydro Tests). Also provided were “weld maps” and MTR’s for client review and inspection. At U.S. Bellows, we are constantly developing and assisting client engineers in this effort toward decarbonation by designing innovative products to accommodate new and unusual design specifications.