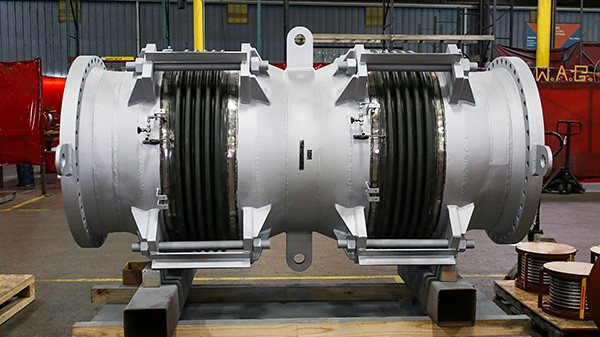

U.S. Bellows, a division of PT&P, custom-designed universal tied expansion joints with oversized, testable bellows for an auxiliary column overhead line in a refinery. This design can also be used in BioFuels plants, Wastewater Treatment Plants, and various Green Energy facilities. The expansion joint pictured is 100″ long and fabricated with carbon steel flanges, liner, cover, and hardware. The bellows are 36″ diameter and formed utilizing Inconel-625 LCF material. The expansion joints are designed for an operating temperature of 650°F at 50 psig with 2.75″ lateral movement. Tests included dye Penetrant examination of all welds, x-ray test of butt-welds, and bellows long seams. We conducted PMI tests on all alloys along with the welds, as well as, a pneumatic test and bellows ply leak test.

The bellows, being two-ply, provide for 100% redundancy; therefore, if a leak occurs in the inner ply (which can be detected by a leak detection system), the outer ply is designed for the full pressure and temperature. Pipe strain, misalignment, and vibration can affect the lifecycle of expansion joints located near pumps, compressors, and other rotating equipment. This design allows for the critical piping system to continue operating while plans for replacement can be formulated. This can prevent unexpected shut-downs saving field maintenance valuable time and money. Two-ply bellows also make it possible to pressure test (using the installed test ports) and inspect for leaks during field inspections and in some cases, if conditions permit, the expansion joint can be tested while in service. Most expansion joints in oil refineries, especially FCC units use two-ply bellows, but they are also ideal for regenerated catalyst standpipe, spent catalyst standpipe, recirculation cooled catalyst flue gas piping, and hot gas expanded piping.