Thermal Expansion in Chilled Water Loops: Why Precision Matters

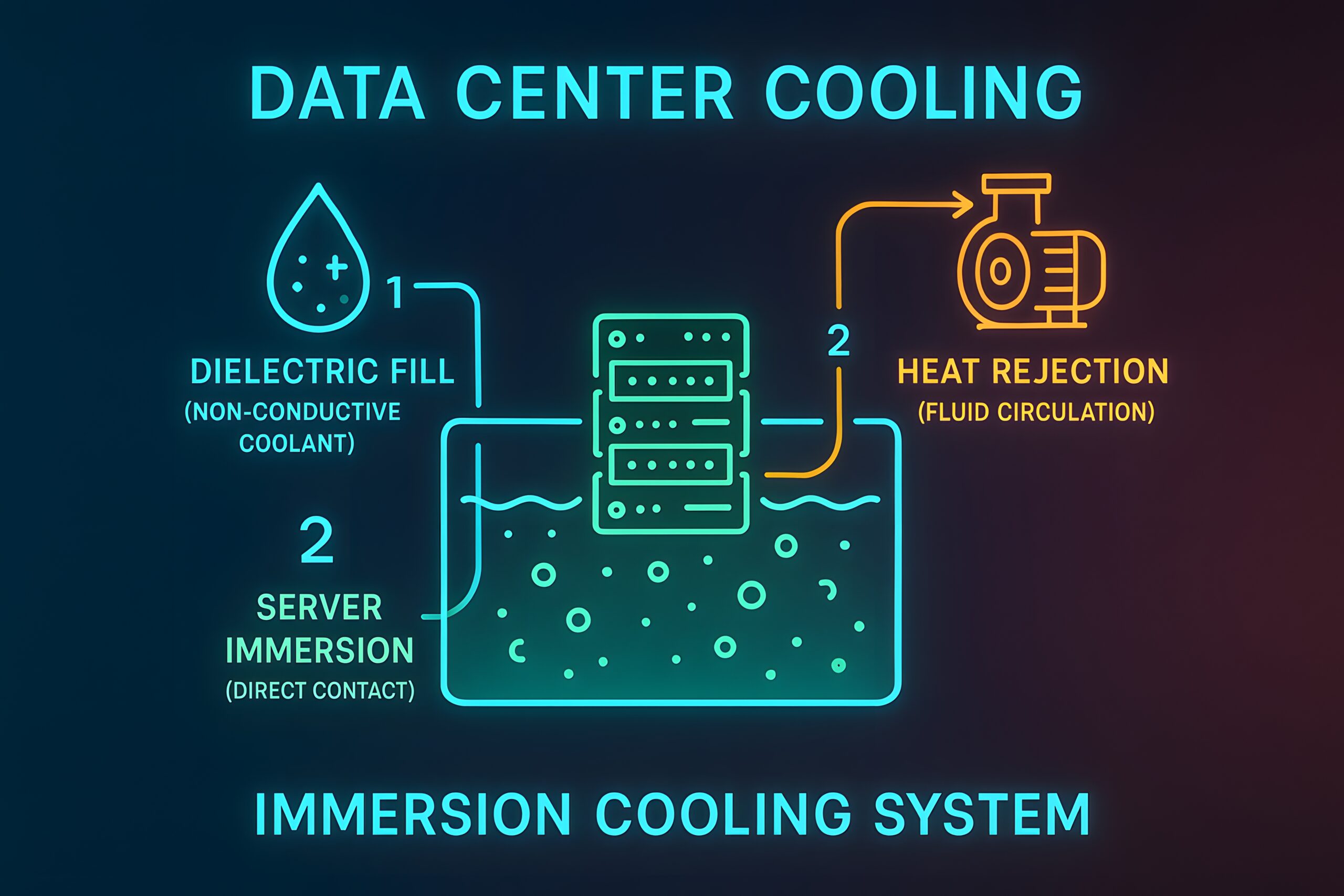

In a data center or industrial facility, chilled water loops serve as the primary cooling infrastructure. These systems are dynamic rather than static. When startup sequences or load-shedding events occur, the resulting temperature shifts cause physical changes within the piping. If these movements are not managed, they can lead to severe structural damage.

The Hook: The Hidden Force of Axial Growth

It is a common misconception that cooling systems face fewer expansion challenges than steam systems. While the temperature delta is smaller, the long pipe runs typical of large facilities amplify physical changes. Any rise in temperature will cause the metal to expand. In a straight run of 100 feet, a modest temperature swing can lead to measurable axial growth. Without a designated place for this energy to go, the pipe will find one, often resulting in buckling or severe lateral deflection.

Compensating for Growth with Metallic Expansion Joints

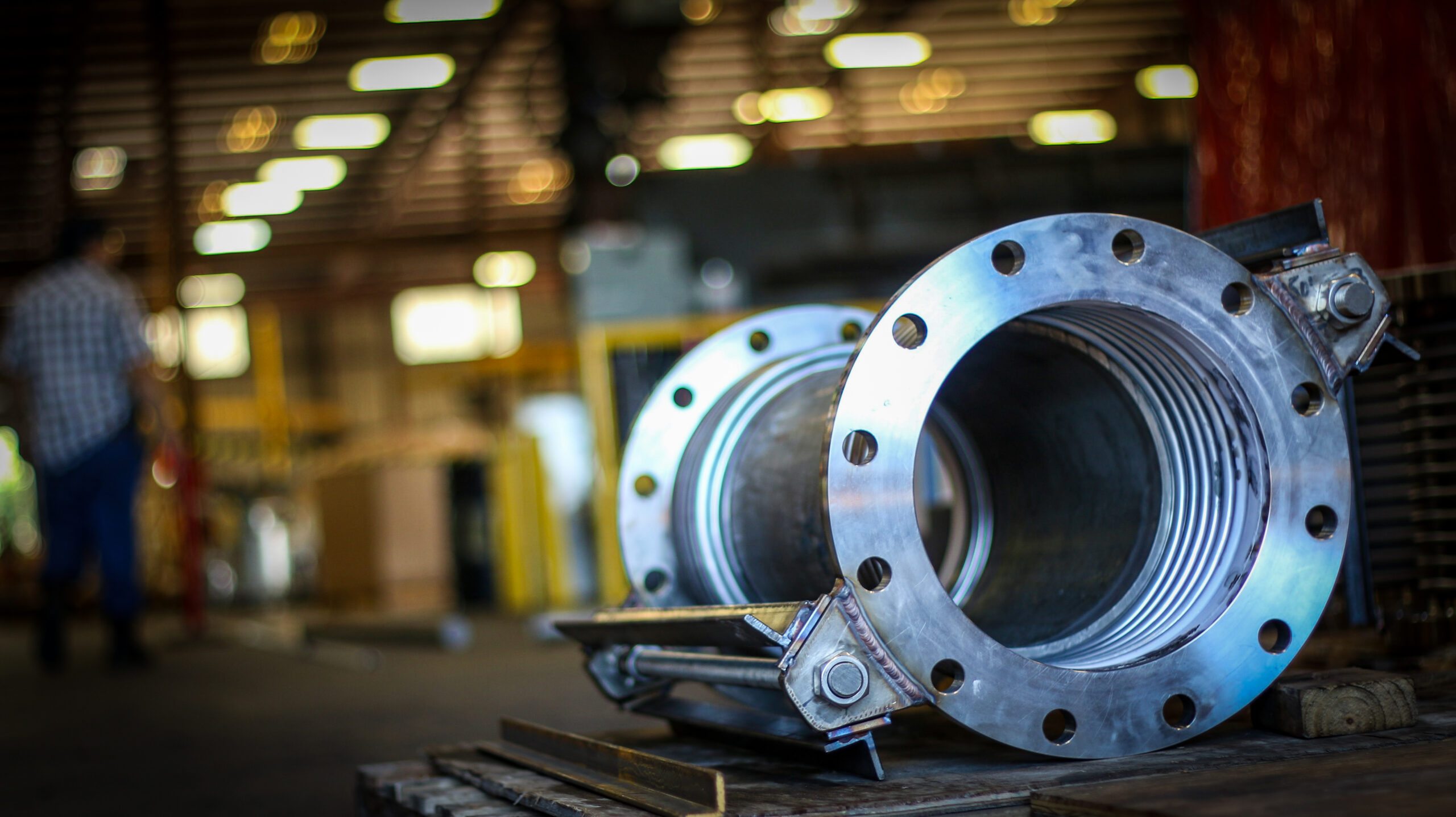

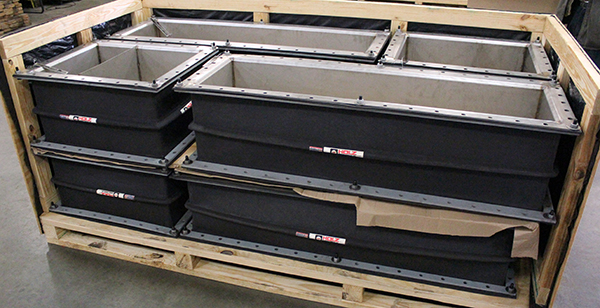

To counteract this movement, engineers integrate metallic expansion joints. Unlike rubber alternatives, metallic bellows offer the longevity and pressure resistance required for high-stakes chilled water environments.

Single bellows expansion joints are the primary solution for absorbing axial movement. As the pipe heats up and grows, the bellows’ thin, convoluted walls compress like an accordion. This prevents the thermal force from transferring further down the line.

In systems with complex routing, universal expansion joints (consisting of two bellows joined by a center pipe) allow for both axial and lateral movement. This is particularly useful when the piping must navigate around structural obstacles while maintaining a constant flow of chilled water.

The Technical Edge: Spring Rate and Flange Protection

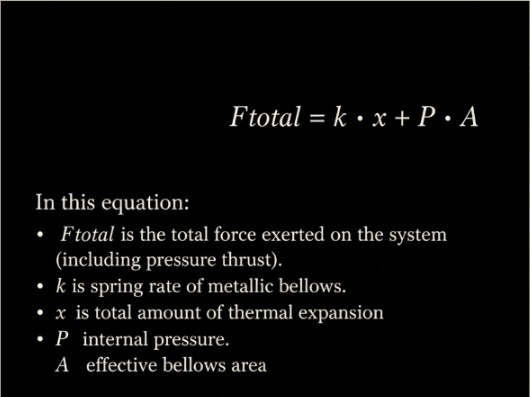

Precision in these systems isn’t just about choosing an expansion joint; it is about the math behind the bellows. Every expansion joint has a spring rate, which is the force required to compress the bellows by a specific distance.

If the spring rate is too high, the bellows acts more like a solid pipe than a flexible cushion. When the pipe expands, it pushes against the CRAC (Computer Room Air Conditioning) unit. The delicate intake valves and flanges on a CRAC unit are not designed to be structural anchors. The design engineer needs to consider all the forces involved: pressure thrust, bellows spring rate force, and any other supports on the piping affecting the CRAC Unit. An overloaded flange can lead to seal failure, leaks, or cracked valve housings. US Bellows engineers calculate these forces to ensure the bellows is flexible enough to protect the equipment while remaining strong enough to contain the system pressure.

Safeguarding Your CRAC Units from Axial Strain with US Bellows

US Bellows provides engineered piping solutions that bridge the gap between theoretical physics and mechanical reliability. By specializing in custom metallic expansion joints, we ensure your mission-critical cooling infrastructure remains stable under shifting thermal loads, preventing costly downtime and equipment failure.

FAQ: Essential Insights on Chilled Water Expansion Joints

How does temperature change affect chilled water piping?

Even in cooling applications, any increase in water temperature causes the metal piping to expand. Because chilled water loops often span long distances, this expansion accumulates into a force that can bend pipes or snap connections at the cooling unit.

Why use metallic bellows instead of rubber connectors?

Metallic bellows provide superior durability and can be custom-engineered with specific spring rates. They are less prone to degradation over time and can handle the pressure surges often found in large-scale chilled water systems.

What happens if the expansion joint spring rate is calculated incorrectly?

If the spring rate is too high, the expansion joint will be stiff and compress only slowly. The force of the expanding pipe will then pass through the joint and “push” on the CRAC unit flange. This can cause the intake valves to warp or leak, leading to system failure.

Can expansion joints handle lateral as well as axial movement?

Yes. While a standard single bellows handles axial (straight-line) growth, a tied universal expansion joint can accommodate lateral offset. This is vital in chilled water layouts where the pipe changes direction near the connection to the cooling unit.

Protect Your CRAC Units with Precision Engineering from US Bellows

Secure your thermal envelope. Protect your cooling assets from the stress of expansion and contraction. Contact the engineering team at US Bellows to request an expansion joint consultation, including custom spring rate analysis, and ensure your CRAC units are protected by the industry’s most reliable metallic expansion joints.

Read More

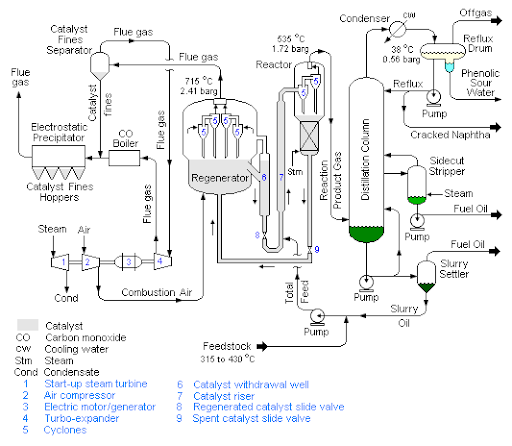

Refinery piping is a dynamic system. In an FCCU, the transition from ambient temperature to whole operation can cause a 100-foot-long pipe to expand by nearly 12 inches. If rigid connections constrain this movement, the resulting stress will concentrate at the weakest point—typically a weld or a critical component of rotating equipment.

Refinery piping is a dynamic system. In an FCCU, the transition from ambient temperature to whole operation can cause a 100-foot-long pipe to expand by nearly 12 inches. If rigid connections constrain this movement, the resulting stress will concentrate at the weakest point—typically a weld or a critical component of rotating equipment.

Rubber expansion joints are the industry standard for liquid handling and vibration control. They are ideal for:

Rubber expansion joints are the industry standard for liquid handling and vibration control. They are ideal for: