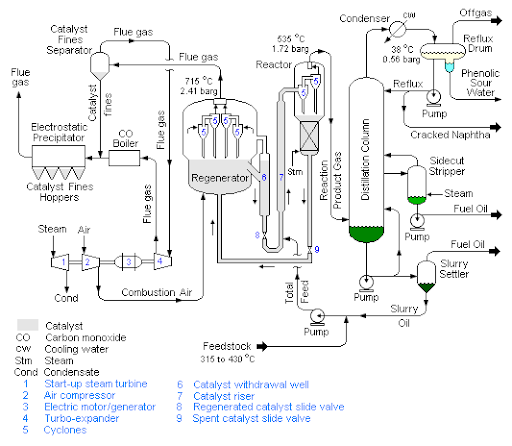

In a modern oil refinery, the fluid catalytic cracking unit (FCCU) serves as the primary engine of production. These units convert heavy crude into high-value products like gasoline and diesel, but they operate under punishing mechanical conditions. With process temperatures frequently reaching 1400∘F (760∘C) and the constant movement of abrasive catalysts, the piping system is under a heavy strain.

The essential components that manage this volatility are high-temperature refractory-lined metal expansion joints. Without these precision-engineered parts, the thermal expansion of massive steel piping would generate forces powerful enough to buckle structural supports, crush turbine nozzles, and trigger catastrophic system breaches.

Engineering for Extreme Heat: Why FCCUs Demand Specialized Joints

Refinery piping is a dynamic system. In an FCCU, the transition from ambient temperature to whole operation can cause a 100-foot-long pipe to expand by nearly 12 inches. If rigid connections constrain this movement, the resulting stress will concentrate at the weakest point—typically a weld or a critical component of rotating equipment.

Refinery piping is a dynamic system. In an FCCU, the transition from ambient temperature to whole operation can cause a 100-foot-long pipe to expand by nearly 12 inches. If rigid connections constrain this movement, the resulting stress will concentrate at the weakest point—typically a weld or a critical component of rotating equipment.

The largest and most critical expansion joints, often refractory-lined, manage significant thermal growth between the massive vessels, between the reactor and the separator/regenerator, and are primarily installed in the overhead line of the FCC Unit.

Expansion joints are also used on the Power Recovery Train (PRT) Connections to handle thermal and dynamic movements, as well as the transfer Lines between equipment and flue gas lines.

The flue gas lines are among the most punishing service environments a component can encounter. These lines transport abrasive catalyst fines and scorching exhaust at high velocities, creating a constant battle against thermal expansion and vibration. Because FCCU flue gas lines operate at extreme temperatures, often exceeding 1200°F, the expansion joints must be engineered with specialized refractory linings and multi-ply bellows to withstand both internal erosion and external stress.

A failure here doesn’t just mean a leak—it can lead to a complete unit shutdown, making the precision of US Bellows engineering and historical design insights essential for maintaining continuous operation in these critical paths.

The Challenge of Catalyst Abrasion

In FCC units, expansion joints must withstand not only heat but also “fluidized” catalysts that act as abrasive media. To combat this internal wear, engineers utilize refractory-lined expansion joints. These “Cold Wall” designs employ internal insulation to keep the outer shell temperature below 650∘F (343∘C). This allows the use of carbon steel for the main piping while isolating the bellows from erosion and extreme thermal degradation.

Managing Pressure Thrust in FCC Units

FCC units undergo cyclic temperature swings, leading to “pipe walking” and intense pressure thrust. Tied Universals, or a hinge/gimbal arrangement, are vital in these configurations. They use constraints to constrain the pressure forces, ensuring that the refinery’s anchors and equipment nozzles are not overloaded by internal system pressure during cycles.

Refinery Engineering Insights: FCCU Expansion Joint FAQ

Q.Why do the FCCU industry (designers/owners) prefer a “Cold Wall” design for both piping and expansion joints?

A. FCCU systems often transport catalysts at temperatures that exceed the allowable stress limits of standard piping materials. A “Cold Wall” design uses an internal refractory lining to lower the shell’s skin temperature, protecting the structural integrity of the pipe. In contrast, the internal flow remains at extreme process temperatures.

FCC units use cold wall designs over hot wall designs primarily for better reliability, easier maintenance, lower metallurgy costs, and reduced thermal stress on components like expansion joints, as cold walls use internal refractory to keep the outer shell cooler (e.g., below 650°F), preventing high-temperature issues like creep and sulfidation seen in hot wall designs where the shell operates near media temperatures. Hot walls are simpler but suffer from significant expansion issues and costly, time-consuming repairs, while cold walls offer better control and a longer lifespan for high-temperature transfer lines.

Q. How does a 2-ply testable bellows prevent refinery downtime?

A. In a 2-ply design, each layer is engineered to handle the full pressure of the system. By installing a pressure gauge or “sniffer” between the plies, operators can detect a leak in the inner layer immediately. This provides a safety buffer, allowing the unit to continue running safely until the next scheduled turnaround.

Q. What materials are best for high-temperature refinery expansion joints?

A. Standard stainless steels often fail due to creep or corrosion at refinery temperatures. We typically use high-nickel alloys such as Inconel 625LCF for its superior fatigue resistance and high-temperature strength, or Incoloy 800/H/HT for its excellent resistance to high temperatures, carburization, and chloride-stress cracking, and 304H/321H stainless steel for applications requiring high-carbon stability.

The US Bellows Advantage: Engineering for 24/7 Refinery Performance

Off-the-shelf components cannot survive the specific “hot wall” or “cold wall” requirements of a modern refinery. At US Bellows, we specialize in custom-engineered solutions that prioritize mechanical safety and long-term cycle life.

Our Value Proposition:

US Bellows delivers refinery-grade expansion joints engineered with advanced alloys (Inconel 625LCF, 304H/321H) and specialized refractory systems that eliminate thermal fatigue and catalyst erosion, backed by 24/7 emergency field services to ensure your FCCU maintains peak uptime.

Key Features of Our Refinery Solutions:

- Multi-Ply Testable Bellows: We offer redundant-ply designs featuring active monitoring ports. If the inner ply reaches its wear limit, the outer ply maintains the pressure boundary, allowing for a planned maintenance window rather than an unscheduled shutdown.

- Custom Refractory Integration: Our designs account for the added stiffness of refractory linings, ensuring accurate stress analysis and predictable movement absorption.

- EJMA-Compliant Design: Every unit is designed according to the Expansion Joint Manufacturers Association (EJMA) standards, ensuring it can handle the specific axial, lateral, and angular movements unique to your facility.

Protect your refinery’s most critical assets by partnering with US Bellows for your next FCCU turnaround. Connect with our engineering team for a custom pipe stress analysis and project quote.