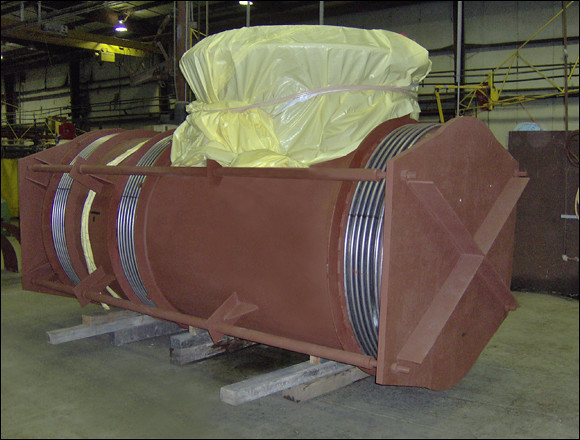

This refractory lined expansion joint is composed of 321 stainless steel bellows and A588-A Corten angle flanges. It is lined with a 4″ thick refractory lining and measures 7″-2″ x 4″-6″ x 134″ F-F. The expansion joint was dye penetrant tested and will be utilized in flue gas service associated with a clean fuels project at an oil refinery.

Tag: Blog

2″-18″ Dia. Custom Tied Universal Expansion Joints Designed for a Chemical Plant

U.S. Bellows custom designed tied universal expansion joints with 304 stainless steel bellows from 2″ to 18″ diameter for a chemical plant in Texas. The expansion joints are designed for 3″ lateral movement at 122°F and 100 psig. The expansion joints were hydro-tested at 150 psig and delivered in six weeks.

Read More54″ Dia. Refurbished Custom Crossover Expansion Joint

US Bellows refurbished a 54″ dia. custom crossover expansion joint for a power plant in Kansas. The flow end and balancing end bellows were replaced. The pressure balanced expansion joint was designed for 1″ axial movement at 700°F and 150 PSIG. The bellows longitudinal weld seams were 100% x-rayed and the assembly was hydro-tested at 180 psig prior to shipment. The refurbishment was completed in three weeks to meet the customer’s outage requirements.

Read MoreUniversal Expansion Joints Custom Designed for a Bioenergy Plant

These universal metallic expansion joints were custom designed for a pipe line in a bioengergy plant. They range from 20″ to 30″ in diameter, and are designed for 2″ lateral movement with a 1,362 lb/in. spring rate. The expansion joints are fabricated entirely from 304 stainless steel and designed for 250°F and 30 psig. Each unit was 100% dye penetrant examined and air tested prior to shipment.

Read More84″ & 14″ Dia. Single Expansion Joints Custom Designed for a Pipe Line in an Utility Plant

| Type: | Single Expansion Joint |

| Size: | 14″ dia. and 84″ Diameter |

| Material: | 304 stainless steel |

| Design | spring rate of 2,530 lb/in., 1″ axial movement at 300°F and 37 psig |

| Testing: | 100% Dye-penetrant | Hydro-tested |

US Bellows custom-designed 14″ dia. and 84″ dia. single expansion joints for a pipeline in a utility plant in Colorado. The bellows are 304 stainless steel and carbon steel was used for the flanges and tie rods. The assemblies were designed for a spring rate of 2,530 lb/in., 1″ axial movement at 300°F and 37 psig. The assemblies were dye penetrant examined and air tested with a delivery of 12 weeks.

Read MorePressure Balanced Tee Expansion Joint Designed for a Boiler Feed Pump Turbine Exhaust

| Type: | Single Expansion Joint |

| Size: | 96″ Dia. x 288″ OAL |

| Material: | Carbon steel with 304 stainless steel |

| Design: | 2″ axial movement at 315°F and 15 PSIG |

| Testing: | 100% Pneumatic-tested |

This pressure balanced tee expansion joint was custom-designed for a boiler feed pump turbine exhaust in a power plant. It is 96″ Dia. x 288″ OAL and fabricated from carbon steel with 304 stainless steel bellows, turning vanes and liners. It is designed for 2″ axial movement at 315°F and 15 PSIG. The expansion joint was 100% dye-penetrant tested, and a chemical cleaning of the interior surfaces was performed to remove any oil and grease. US Bellows also performed a pneumatic test at 23 PSIG.

Read More36″ Dia. Tied Universal Expansion Joint with Stainless Steel Bellows

This tied universal expansion joint is 36″ Dia. x 47-3/8″ OAL and is fabricated from carbon steel with stainless steel bellows. It is designed for 1/2″ lateral movement, 3,116 lb./in. lateral spring rate at 200°F and 100 psig. The expansion joint was dye penetrant examined and hydrotested prior to shipment.

Universal Expansion Joint with Refractory Lining and Pantographic Linkage

US Bellows fabricated this 28″ dia., 109″ long universal expansion joint with 1″ thick AA-22 abrasion-resistant refractory lining and pantographic linkage for an FCC unit in an oil refinery. The entire assembly is fabricated from 304H stainless steel with carbon steel pantographs. This expansion joint has two-ply testable bellows with wire mesh strip between the plies. It is designed for an axial movement of 5″, a lateral movement of 5-1/2″ at 1425°F and 45 psig. This unit was 100% dye penetrant tested, all pressure retaining welds were 100% radiographed and the unit was pneumatic tested prior to shipping to Oklahoma.

Read More42″ Dia. Single Tied Expansion Joints Designed for a Solar Electric Generation Facility

| Type: | Single Expansion Joint |

| Size: | 40″ and 42″ diameter |

| Material: | 304 Stainless Steel | Carbon Steel |

| Design | lateral movement of 1/2″, and 15 PSIG at 250°F |

| Testing: | 100% Dye-penetrant | Hydro-tested |

These single tied expansion joints are 40″ and 42″ diameter and were designed for a solar electric generation facility. The bellows and flow liner are 304 stainless steel. The stub ends are fabricated from carbon steel. The expansion joints were designed for a lateral movement of 1/2″, and 15 PSIG at 250°F. They were 100% dye penetrant examined and hydro-tested prior to shipping to California.

Read More60″ Dia. Pressure Balanced Elbow Expansion Joint for a Power Generation Plant

60″ Dia. Pressure Balanced Elbow Expansion Joint for a Power Generation Plan

This pressure balanced elbow expansion joint is 60″ diameter and 240″ overall length and was custom designed for a power generation plant in South Carolina. It was fabricated from carbon steel with 304 stainless steel bellows. The expansion joint was designed for an axial compression of 1″, lateral of 1″, and 100 PSIG at 100°F

Fabric Expansion Joints Custom Designed for an Offshore Oil Extraction and Natural Gas Project

These fabric expansion joints were custom designed for offshore oil extraction and natural gas project. They are 105″ dia. x 24″ O.A.L. 309 stainless steel was used for the duct, 310 for the liners, 316 for the covers, 321 for the studs, 309 for the flanges. The fabric belt was a three-layer belt with an inner layer of glass cloth, a layer of Kaowool, and an outside layer of reinforced PTFE. The expansion joints were designed for 1 psig at a temperature of 1100°F. They are designed for 4″ axial compression, a 1″ extension, and a 0.5″ lateral offset. All welds were 100% dye-penetrant examined prior to shipment.

Single Expansion Joint for an Offshore Deep Drilling Platform

| Type: | Single Expansion Joint |

| Size: | 16″ diameter, 21-1/2″ OAL |

| Material: | 321 stainless steel |

| Design | 450°F at 8 psig |

| Testing: | 100% Dye-penetrant | Air and Soap-tested |

These single expansion joint are refurbished with 321 stainless steel bellows for an offshore deepwater drilling platform. They are 16″ diameter, 21-1/2″ OAL, and designed for 450°F at 8 psig. The expansion joints were dye penetrant examined, and an air and soap bubble test was performed prior to shipment.

Read MorePressure Balanced Expansion Joint for a Nuclear Facility

This pressure balanced expansion joint was custom made for a nuclear facility in Texas. It is 66″ID x 169″ OAL. This expansion joint was fabricated with 304 stainless steel bellows and carbon tee, pipe and tie rods. 100% dye-penetrant and soap and air tested, its operating conditions were 15 PSIG at 300°F for 1 1/4″ axial compression.

Read MoreCustom Designed Universal Expansion Joint for Gas Turbine Application

This custom designed universal expansion joint is to be used for a gas turbine application. Dimensions are 30” DIA x 90” OAL and materials used for fabrication were 321 ss bellows, liners, and carbon steel pipes. This expansion joint was 100% x-ray, dye-penetrant, and hydro tested. Operating conditions were 96 PSIG at 550°F for 2″ lateral and 3/8” axial compression.

Read More118″ Universal Expansion Joint for Steam Service

This 118″ diameter tied universal expansion joint was designed for steam service in a power plant in Alaska. The expansion joint duct, tie rods and cover are fabricated from carbon steel with 304 stainless steel bellows and liner. The overall length is 225″. It was designed for 250°F at 7.25 PSIG and 3.52Pquot; of lateral movement. Dye-penetrant testing, spot x-ray and an air and soap test were performed on the universal expansion joint assembly prior to shipping.

Read More31″ I.D. Custom Turbine Expansion Joint

| Type: | Single Expansion Joint |

| Size: | 31″ |

| Material: | 321 stainless steel with Inconel 625 |

| Design: | 36″ long and is designed for 70 PSIG at 450 deg. F and axial travel of 4″ |

| Testing: | 100% Dye-penetrant | Hydro-tested |

Custom fabricated 31″ I.D. turbine expansion joint was designed and fabricated to be placed in service for a company in Texas. The expansion joint unit was reverse engineered, from the previous unit, with improvements to the current design. It is fabricated from 321 stainless steel with Inconel 625 bellows. The turbine expansion joint is 36″ long and is designed for 70 PSIG at 450 deg. F and axial travel of 4″. The expansion joint was 100% dye-penetrant examined and hydro-tested prior to being shipped to the customer.

Read MoreExpansion Joint Components for Nuclear Facility

These expansion joint components were fabricated for a pressure balanced expansion joint in a nuclear power facility in Pennsylvania. They are 46″ square, fabricated from carbon steel duct with Inconel 625 bellows, and 321 stainless steel liner. The design conditions were +/- 0.875″ axial compression, 1,346 lb./in. lateral spring rate and 15 PSIG at 250°F. All welds were 100% dye penetrant examined and a pneumatic pressure test at 15 PSIG was conducted prior to shipping.

Read More

Tied Universal Expansion Joint with Control Rods for an Oil Recovery Project

This tied universal expansion joint with control rods was designed for an oil recovery plant in Canada. It is 48″ in diameter and 68″ in overall length. This expansion joint was designed for 1″ compression, 4″ lateral and 15 psig at 150°F. The pipe was fabricated from A-36 carbon steel material and the bellows were fabricated from 316L stainless steel. A dye penetrant exam, air and soap test, along with a vacuum test was conducted prior to shipping.

Custom Thick Wall Flanged and Flued Head Expansion Joints for Heat Exchangers in California

|

Various sizes of thick wall flanged and flued head expansion joints were custom designed for heat exchangers in California. Two are 30″ in diameter and two are 18″ in diameter. They were designed for 1″ axial extension and 14 psig at 300°F. All four expansion joints were fabricated from ASTM A-516 Gr. 70 carbon steel material. A dye penetrant exam was conducted prior to shipping.

Read MoreNeoprene Fabric Expansion Joints for a Ventilation Fan Intake Duct

Neoprene fabric expansion joints were custom-designed for a ventilation fan intake duct in a power plant. They are 42″ in diameter and are 65″ in overall length. They were designed for 1/4″ axial movement, 1/8″ lateral deflection, and a 100″ water column at 200°F. The expansion joints are fabricated with a neoprene reinforced belt with stainless steel clamps, carbon steel spool pipe, and angle flange end. Each joint was 100% dye-penetrant examined prior to shipping.

- « Previous Page

- 1

- …

- 6

- 7

- 8

- 9

- 10

- …

- 16

- Next Page »