| Type: |

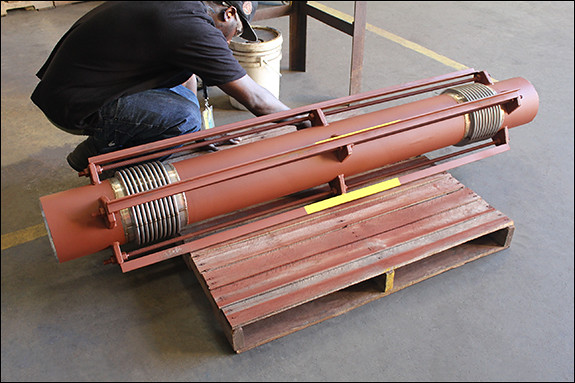

Universal Expansion Joints |

| Size: |

9′ 2″ diameter and 22′ 10″ OAL |

| Material: |

321 Stainless Steel and Carbon Steel |

| Design: |

250°F at 7.25 psig/FV and 1.5° angulation |

| Testing: |

Dye-penetrant, high vacuum (70 mbar), and hydrotested |

U.S. Bellows custom-designed 23 of these tied universal expansion joints for a combined cycle power plant in Texas. This expansion joint is one of 23 units constructed and has a nominal diameter of 9′ 2″ with an overall length of 22′ 10″. The bellows are fabricated from 321 stainless steel with a carbon steel shell and tie rods. This tied joint is part of a condenser duct complex that is designed to operate at 250° F at 7.25 psig/FV, with compression of 3/16″, lateral deflection of 5 7/8″, and +/- 1.5° angulation. All expansion joints were 100% dye-penetrant tested, hydro-tested, and high vacuum (70 mbar) tested prior to shipment.

This expansion joint was featured in our lastest Technical Bulletin:

Click here to learn more about air-cooled condenser expansion joints

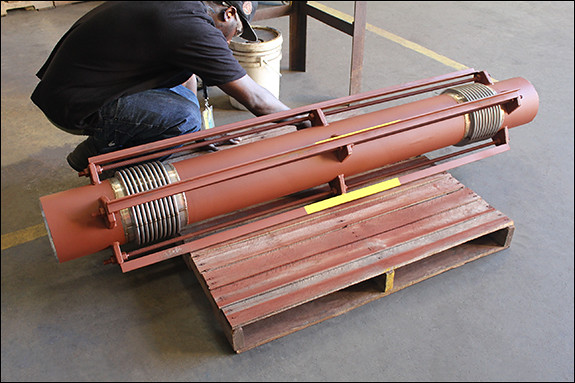

| Type: |

Universal Expansion Joints |

| Size: |

9′ 2″ diameter and 22′ 10″ OAL |

| Material: |

321 Stainless Steel and Carbon Steel |

| Design: |

250°F at 7.25 psig/FV and 1.5° angulation |

| Testing: |

Dye-penetrant, high vacuum (70 mbar), and hydrotested |

U.S. Bellows custom-designed 23 of these tied universal expansion joints for a combined cycle power plant in Texas. This expansion joint is one of 23 units constructed and has a nominal diameter of 9′ 2″ with an overall length of 22′ 10″. The bellows are fabricated from 321 stainless steel with a carbon steel shell and tie rods. This tied joint is part of a condenser duct complex that is designed to operate at 250° F at 7.25 psig/FV, with compression of 3/16″, lateral deflection of 5 7/8″, and +/- 1.5° angulation. All expansion joints were 100% dye-penetrant tested, hydro-tested, and high vacuum (70 mbar) tested prior to shipment.

This expansion joint was featured in our lastest Technical Bulletin:

Click here to learn more about air-cooled condenser expansion joints

Read More

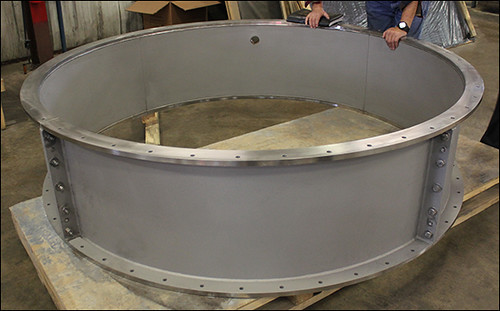

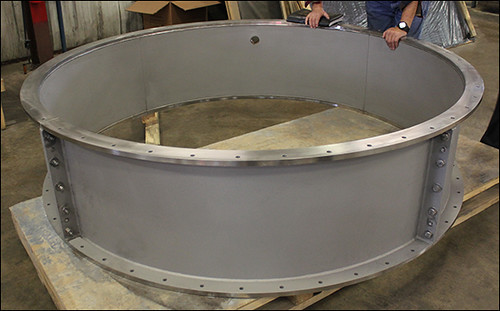

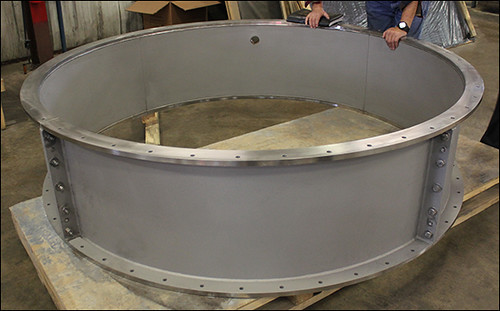

| Type: |

Hinged Expansion Joints |

| Size: |

110″ diameter and 39 3/8″ OAL |

| Material: |

321 Stainless Steel and Carbon Steel |

| Design |

250°F at 7.25 psig/FV and +/- 3° angulation |

| Testing: |

Dye-penetrant and high vacuum (70 mbar) tested |

U.S. Bellows custom-designed this hinged expansion joint for a combined cycle power plant in Texas. This expansion joint is one of 11 units constructed and has a nominal diameter of 110″ with an overall length of 39 3/8″. The bellows are fabricated from 321 stainless steel with a carbon steel weld ends, cover, and hinges. This hinged joint is part of a condenser duct complex that is designed to operate at 250°F at 7.25 psig/FV, with +/- 3° angulation. All expansion joint welds were 100% dye-penetrant tested and high vacuum (70 mbar) tested prior to shipment.

| Type: |

Hinged Expansion Joints |

| Size: |

110″ diameter and 39 3/8″ OAL |

| Material: |

321 Stainless Steel and Carbon Steel |

| Design |

250°F at 7.25 psig/FV and +/- 3° angulation |

| Testing: |

Dye-penetrant and high vacuum (70 mbar) tested |

U.S. Bellows custom-designed this hinged expansion joint for a combined cycle power plant in Texas. This expansion joint is one of 11 units constructed and has a nominal diameter of 110″ with an overall length of 39 3/8″. The bellows are fabricated from 321 stainless steel with a carbon steel weld ends, cover, and hinges. This hinged joint is part of a condenser duct complex that is designed to operate at 250°F at 7.25 psig/FV, with +/- 3° angulation. All expansion joint welds were 100% dye-penetrant tested and high vacuum (70 mbar) tested prior to shipment.

Read More

| Type: |

Clamshell Pipe Spool |

| Size: |

85.45″ in diameter and 21.5″ face-to-face |

| Material: |

321H Stainless Steel |

| Design |

950°F |

| Testing: |

Dye-Penetrant |

U.S. Bellows custom designed this clamshell pipe spool for an exhaust duct application at a gas turbine facility in Texas. The units were completely fabricated from 321H stainless steel. It is 85.45″ in diameter and 21.5″ face-to-face. The clamshell was designed for an operating temperature of 950°F. A dye-penetrate test was performed prior to shipment.

| Type: |

Clamshell Pipe Spool |

| Size: |

85.45″ in diameter and 21.5″ face-to-face |

| Material: |

321H Stainless Steel |

| Design |

950°F |

| Testing: |

Dye-Penetrant |

U.S. Bellows custom designed this clamshell pipe spool for an exhaust duct application at a gas turbine facility in Texas. The units were completely fabricated from 321H stainless steel. It is 85.45″ in diameter and 21.5″ face-to-face. The clamshell was designed for an operating temperature of 950°F. A dye-penetrate test was performed prior to shipment.

Read More

| Type: |

Tied Universal Expansion Joint |

| Size: |

178″ in diameter and 276″ in length |

| Material: |

321 Stainless Steel and Carbon Steel |

| Design: |

248°F at 22.5 psig, operating load of 1256 lb/in, and 6.25″ lateral deflection |

| Testing: |

Dye-Penetrant and Soap & Air |

U.S. Bellows custom designed five of these 178″ tied universal expansion joints for an exhaust duct application in a power plant in Virginia. The expansion joints are 178″ in diameter and 276″ in length. The bellows were fabricated from 321 stainless steel and the rest of the assembly from carbon steel. They are designed for an operating temperature of 248°F at 22.5 psig, an operating load of 1256 lb/in, and 6.25″ of lateral deflection. All units were 100% dye-penetrant and soap and air tested prior to shipment. Because of the sheer size of the units, all of the tie rod supports were FEA analyzed.

This expansion joint was featured in our lastest Technical Bulletin:

Click here to learn more about air-cooled condenser expansion joints

| Type: |

Tied Universal Expansion Joint |

| Size: |

178″ in diameter and 276″ in length |

| Material: |

321 Stainless Steel and Carbon Steel |

| Design: |

248°F at 22.5 psig, operating load of 1256 lb/in, and 6.25″ lateral deflection |

| Testing: |

Dye-Penetrant and Soap & Air |

U.S. Bellows custom designed five of these 178″ tied universal expansion joints for an exhaust duct application in a power plant in Virginia. The expansion joints are 178″ in diameter and 276″ in length. The bellows were fabricated from 321 stainless steel and the rest of the assembly from carbon steel. They are designed for an operating temperature of 248°F at 22.5 psig, an operating load of 1256 lb/in, and 6.25″ of lateral deflection. All units were 100% dye-penetrant and soap and air tested prior to shipment. Because of the sheer size of the units, all of the tie rod supports were FEA analyzed.

This expansion joint was featured in our lastest Technical Bulletin:

Click here to learn more about air-cooled condenser expansion joints

Read More

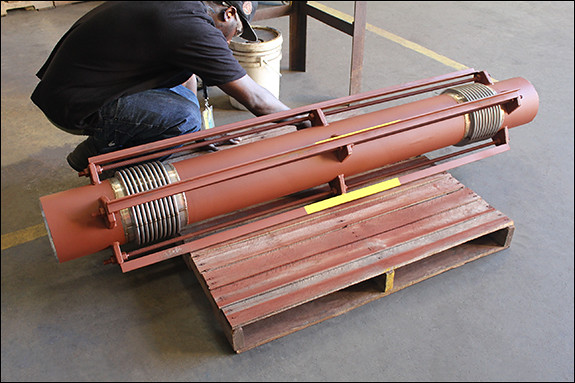

| Type: |

Elbow Pressure Balanced Expansion Joint |

| Size: |

30″ in diameter and 118″ in length |

| Material: |

321 Stainless Steel and Carbon Steel |

| Design: |

400°F at 50 psig, an operating load of 959 lb/in, and 1 3/8″ in axial compression |

| Testing: |

Hydrotested |

This custom tied elbow pressure balanced expansion joint was designed for an acetic acid producing application at a chemical plant in Texas. It is 30″ in diameter and 118″ in length. The bellows are fabricated from 321 stainless steel and all the other components are from carbon steel. It is designed for 400°F at 50 psig, an operating load of 959 lb/in, and 1 3/8″ in axial compression. The expansion joint hydrotested prior to shipment.

| Type: |

Elbow Pressure Balanced Expansion Joint |

| Size: |

30″ in diameter and 118″ in length |

| Material: |

321 Stainless Steel and Carbon Steel |

| Design: |

400°F at 50 psig, an operating load of 959 lb/in, and 1 3/8″ in axial compression |

| Testing: |

Hydrotested |

This custom tied elbow pressure balanced expansion joint was designed for an acetic acid producing application at a chemical plant in Texas. It is 30″ in diameter and 118″ in length. The bellows are fabricated from 321 stainless steel and all the other components are from carbon steel. It is designed for 400°F at 50 psig, an operating load of 959 lb/in, and 1 3/8″ in axial compression. The expansion joint hydrotested prior to shipment.

Read More

| Type: |

Gimbal Expansion Joint |

| Size: |

8″ x 22.5″ and 10″ x 23.5″ |

| Material: |

321 & 316 Stainless Steel/Carbon Steel |

| Design: |

370°F at 160 psig, 10° angular rotation |

| Testing: |

Dye Penetrant and Hydro tested |

These gimbal expansion joints were custom designed by U.S. Bellows for a pipeline in Texas. Units are an 8″ gimbal that is 22.5″ OAL and 10″ gimbal that is 23.5″ OAL. Each unit incorporated square gimbal design for the gimbal structure. The bellows and flanges were fabricated from 321 stainless steel, the liners from 316 stainless steel, and cover and hinge parts from carbon steel. They were designed for an operating temperature of 370°F at 160 psig with 10° of angular rotation. All unites were dye penetant and hydotested prior to shipment.

| Type: |

Gimbal Expansion Joint |

| Size: |

8″ x 22.5″ and 10″ x 23.5″ |

| Material: |

321 & 316 Stainless Steel/Carbon Steel |

| Design: |

370°F at 160 psig, 10° angular rotation |

| Testing: |

Dye Penetrant and Hydro tested |

These gimbal expansion joints were custom designed by U.S. Bellows for a pipeline in Texas. Units are an 8″ gimbal that is 22.5″ OAL and 10″ gimbal that is 23.5″ OAL. Each unit incorporated square gimbal design for the gimbal structure. The bellows and flanges were fabricated from 321 stainless steel, the liners from 316 stainless steel, and cover and hinge parts from carbon steel. They were designed for an operating temperature of 370°F at 160 psig with 10° of angular rotation. All unites were dye penetant and hydotested prior to shipment.

Read More

| Type: |

Single Expansion Joint |

| Size: |

2″ Diameter/18″ long & 4″ Diameter/18″ long |

| Material: |

304 Stainless Steel | CS |

| Design |

400°F at 150 psig |

| Testing: |

100% Hydro-tested |

U.S. Bellows custom designed these single expansion joints for an oil pipeline application. 30 of the units are 2″ in diameter and 18″ OAL and 10 of the units are 4″ in diameter and 18″ OAL. The bellows were fabricated from 304 stainless steel with the pipe spool and flanges from carbon steel. They are designed for an operating pressure of 150 psig and an operating temperature of 400°F. All units were hydro-tested prior to shipment.

| Type: |

Single Expansion Joint |

| Size: |

2″ Diameter/18″ long & 4″ Diameter/18″ long |

| Material: |

304 Stainless Steel | CS |

| Design |

400°F at 150 psig |

| Testing: |

100% Hydro-tested |

U.S. Bellows custom designed these single expansion joints for an oil pipeline application. 30 of the units are 2″ in diameter and 18″ OAL and 10 of the units are 4″ in diameter and 18″ OAL. The bellows were fabricated from 304 stainless steel with the pipe spool and flanges from carbon steel. They are designed for an operating pressure of 150 psig and an operating temperature of 400°F. All units were hydro-tested prior to shipment.

Read More

| Type: |

Thick-Wall Expansion Joints |

| Size: |

36″-84″ in diameter |

| Design: |

A516-70 Carbon Steel/304 Stainless Steel |

| Material: |

250″ water column |

| Testing: |

100% dye-penetrant and air, soap and bubble tested |

U.S. Bellows designed this thick wall flange and flued expansion joint for a sulphuric acid plant in Kentucky. Units were designed with various dimensions from 36″-84″ in diameter. They were all fabricated from A516-70 carbon steel and 304 stainless steel. The expansion joint is designed for a 250″ water column. All units were dye-penetrant, soap and air bubble, and hydro tested prior to shipment.

| Type: |

Thick-Wall Expansion Joints |

| Size: |

36″-84″ in diameter |

| Design: |

A516-70 Carbon Steel/304 Stainless Steel |

| Material: |

250″ water column |

| Testing: |

100% dye-penetrant and air, soap and bubble tested |

U.S. Bellows designed this thick wall flange and flued expansion joint for a sulphuric acid plant in Kentucky. Units were designed with various dimensions from 36″-84″ in diameter. They were all fabricated from A516-70 carbon steel and 304 stainless steel. The expansion joint is designed for a 250″ water column. All units were dye-penetrant, soap and air bubble, and hydro tested prior to shipment.

Read More

| Type: |

In-line Pressure Balanced Expansion Joint |

| Size: |

12″ in diameter and 32″ in overall length |

| Design: |

304 Stainless Steel |

| Material: |

200°F at 55 PSIG, with 7/8″ of axil compression and .07″ of lateral movement |

| Testing: |

100% dye-penetrant, PMI, X-Ray, and hydro tested |

These inline pressure balanced expansion joints were custom-designed by US Bellows for a wastewater treatment plant in California. The units are 12″ in diameter and 32″ in overall length. All components of the expansion joints (bellows, covers, liners, rings, and flanges) were completely fabricated from 304 stainless steel. They are designed for an operating temperature 200°F at 55 PSIG, with 7/8″ of axial compression and .07″ of lateral movement. All units were 100% dye-penetrant, PMI, X-Ray, and hydro-tested prior to shipment.

| Type: |

In-line Pressure Balanced Expansion Joint |

| Size: |

12″ in diameter and 32″ in overall length |

| Design: |

304 Stainless Steel |

| Material: |

200°F at 55 PSIG, with 7/8″ of axil compression and .07″ of lateral movement |

| Testing: |

100% dye-penetrant, PMI, X-Ray, and hydro tested |

These inline pressure balanced expansion joints were custom-designed by US Bellows for a wastewater treatment plant in California. The units are 12″ in diameter and 32″ in overall length. All components of the expansion joints (bellows, covers, liners, rings, and flanges) were completely fabricated from 304 stainless steel. They are designed for an operating temperature 200°F at 55 PSIG, with 7/8″ of axial compression and .07″ of lateral movement. All units were 100% dye-penetrant, PMI, X-Ray, and hydro-tested prior to shipment.

Read More

| Type: |

Fabric Expansion Joint |

| Size: |

83″ diameter / 20″ face-to-face |

| Material: |

PTFE Fabric Belt / 304 Stainless Steel |

| Design: |

500°-1500°F at +/-2″ water column & 1 1/2″-6 1/2″ axial compression |

| Testing: |

100% Dye-Penetrant |

U.S. Bellows custom engineered this fabric expansion joint for a gas and water vapor application at a rotating dryer facility. It is fabricated from a 3-layer PTFE belt with a 304 stainless steel frame and 2205 duplex framing. The unit is 83″ in diameter and 20″ face-to-face. The expansion joint is designed for an operating temperature ranging from 500°-1500°F at a +/- 2″ water column pressure and 1 1/2″-6 1/2″ of axial compression. A 100% dye-penetrant examination was conducted on the unit prior to shipment.

| Type: |

Fabric Expansion Joint |

| Size: |

83″ diameter / 20″ face-to-face |

| Material: |

PTFE Fabric Belt / 304 Stainless Steel |

| Design: |

500°-1500°F at +/-2″ water column & 1 1/2″-6 1/2″ axial compression |

| Testing: |

100% Dye-Penetrant |

U.S. Bellows custom engineered this fabric expansion joint for a gas and water vapor application at a rotating dryer facility. It is fabricated from a 3-layer PTFE belt with a 304 stainless steel frame and 2205 duplex framing. The unit is 83″ in diameter and 20″ face-to-face. The expansion joint is designed for an operating temperature ranging from 500°-1500°F at a +/- 2″ water column pressure and 1 1/2″-6 1/2″ of axial compression. A 100% dye-penetrant examination was conducted on the unit prior to shipment.

Read More

| Type: |

Elbow Pressure Balanced Expansion Joint |

| Size: |

111″ x 115″ x 60″ |

| Material: |

Incoloy 625 / Carbon Steel |

| Design: |

350°F at 15 psig with 1/2″ of axial compression and 1/4″ of lateral deflection |

| Testing: |

Hydrotest |

This 60″ elbow pressure balanced expansion joint was custom designed by U.S. Bellows for a power plant in California. The bellows are fabricated from Inconel 625 LCF while the remainder of the expansion joint from carbon steel. It is designed for an operating temperature of 350°F at 15 psig with 1/2″ of axial compression and 1/4″ of lateral deflection. The unit was hydrotested prior to shipment.

| Type: |

Elbow Pressure Balanced Expansion Joint |

| Size: |

111″ x 115″ x 60″ |

| Material: |

Incoloy 625 / Carbon Steel |

| Design: |

350°F at 15 psig with 1/2″ of axial compression and 1/4″ of lateral deflection |

| Testing: |

Hydrotest |

This 60″ elbow pressure balanced expansion joint was custom designed by U.S. Bellows for a power plant in California. The bellows are fabricated from Inconel 625 LCF while the remainder of the expansion joint from carbon steel. It is designed for an operating temperature of 350°F at 15 psig with 1/2″ of axial compression and 1/4″ of lateral deflection. The unit was hydrotested prior to shipment.

Read More

| Type: |

Rectangular Fabric Expansion Joint |

| Size: |

136″ x 45″ x 12″ |

| Material: |

PTFE Fiberglass Reinforced Fabric Belt / 304 Stainless Steel |

| Design |

-20°F to 650°F at a +/- 100″ water column |

| Testing: |

100% Dye-Penetrant |

U.S. Bellows fabricated this rectangular fabric expansion joint for a natural gas application at a gas turbine facility. The fabric belt is made from PTFE fiberglass reinforced and the frame and liner from 304 stainless steel. The unit is 136″ long x 45″ wide x 12″ face-to-face. It is designed for an operating temperature ranging from -20°F to 650°F with a pressure of +/- 100″ water column. A dye penetrant examination was performed on all welds prior to shipment.

| Type: |

Rectangular Fabric Expansion Joint |

| Size: |

136″ x 45″ x 12″ |

| Material: |

PTFE Fiberglass Reinforced Fabric Belt / 304 Stainless Steel |

| Design |

-20°F to 650°F at a +/- 100″ water column |

| Testing: |

100% Dye-Penetrant |

U.S. Bellows fabricated this rectangular fabric expansion joint for a natural gas application at a gas turbine facility. The fabric belt is made from PTFE fiberglass reinforced and the frame and liner from 304 stainless steel. The unit is 136″ long x 45″ wide x 12″ face-to-face. It is designed for an operating temperature ranging from -20°F to 650°F with a pressure of +/- 100″ water column. A dye penetrant examination was performed on all welds prior to shipment.

Read More

| Type: |

Rectangular Expansion Joint |

| Size: |

106″ x 72″ x 15″ |

| Design: |

310 Stainless Steel Bellows / Carbon Steel |

| Material: |

-20 – 1000°F / +/- 5″ water column |

| Testing: |

100% dye-penetrant tested |

US Bellows designed this rectangular expansion joint for a gas turbine facility in California. It was custom-designed with one 6″ x 6″ square convolution. The dimensions of this unit were 106″ x 72″ x 15″. The bellows were fabricated from 310 stainless steel, and the frame from carbon steel. It is designed for an operating temperature from -20°F to +1,000°F at +/- 5″ water column. The unit was 100% dye-penetrant tested prior to shipment.

| Type: |

Rectangular Expansion Joint |

| Size: |

106″ x 72″ x 15″ |

| Design: |

310 Stainless Steel Bellows / Carbon Steel |

| Material: |

-20 – 1000°F / +/- 5″ water column |

| Testing: |

100% dye-penetrant tested |

US Bellows designed this rectangular expansion joint for a gas turbine facility in California. It was custom-designed with one 6″ x 6″ square convolution. The dimensions of this unit were 106″ x 72″ x 15″. The bellows were fabricated from 310 stainless steel, and the frame from carbon steel. It is designed for an operating temperature from -20°F to +1,000°F at +/- 5″ water column. The unit was 100% dye-penetrant tested prior to shipment.

Read More

| Type: |

Externally Pressurized Expansion Joints |

| Size: |

4″ Diameter / Single: 50″ and double: 87″ Face-to-Face |

| Design: |

Inconel 625 Bellows / Carbon Steel |

| Material: |

400°F / 400 psig |

| Testing: |

Hydro-tested at 600 psig |

These single externally pressurized expansion joints were custom designed by U.S. Bellows for a hot water piping system at an Air Force facility in California. All units are 4″ in diameter, with the single units having a length of 50″ face-to-face and double units having a length of 87″ face-to-face. The expansion joint’s bellows were fabricated from Inconel 625 and all other components from carbon steel. They are designed for a temperature of 400°F at 400 psig with 4″ and 8″ of axial compression. All units were hydro-tested at 600 psig prior to shipment.

| Type: |

Externally Pressurized Expansion Joints |

| Size: |

4″ Diameter / Single: 50″ and double: 87″ Face-to-Face |

| Design: |

Inconel 625 Bellows / Carbon Steel |

| Material: |

400°F / 400 psig |

| Testing: |

Hydro-tested at 600 psig |

These single externally pressurized expansion joints were custom designed by U.S. Bellows for a hot water piping system at an Air Force facility in California. All units are 4″ in diameter, with the single units having a length of 50″ face-to-face and double units having a length of 87″ face-to-face. The expansion joint’s bellows were fabricated from Inconel 625 and all other components from carbon steel. They are designed for a temperature of 400°F at 400 psig with 4″ and 8″ of axial compression. All units were hydro-tested at 600 psig prior to shipment.

Read More

|

US Bellows custom designed and fabricated thick-wall flanged and flued head expansion joints for a sulfuric acid plant in Chicago, IL. The units will be used for a chemical furnace and converter project. The expansion joints vary in size from 36″ to 70″ in diameter. The units were fabricated from 304 stainless steel in 1022° F temperatures, with an operating pressure of 93° H2O water column. All welds were dye penetrant, and soap and air tested prior to shipment.

US Bellows custom designed and fabricated thick-wall flanged and flued head expansion joints for a sulfuric acid plant in Chicago, IL. The units will be used for a chemical furnace and converter project. The expansion joints vary in size from 36″ to 70″ in diameter. The units were fabricated from 304 stainless steel in 1022° F temperatures, with an operating pressure of 93° H2O water column. All welds were dye penetrant, and soap and air tested prior to shipment.

Read More

U.S. Bellows designed single hinged expansion joints for a pipeline in Mexico. They are 12″ in diameter and 12″ in length. The bellows were fabricated from 304 stainless steel, and the flanges and hinge hardware from carbon steel. The expansion joints are designed for an operating pressure of 150 psig at 150°F, and rated for 5° of angular movement. All units were 100% dye-penetrant and hydro-tested per ASME B31-3 prior to shipment.

U.S. Bellows designed single hinged expansion joints for a pipeline in Mexico. They are 12″ in diameter and 12″ in length. The bellows were fabricated from 304 stainless steel, and the flanges and hinge hardware from carbon steel. The expansion joints are designed for an operating pressure of 150 psig at 150°F, and rated for 5° of angular movement. All units were 100% dye-penetrant and hydro-tested per ASME B31-3 prior to shipment.

Read More

U.S. Bellows custom designed this universal expansion joint for a steam line extraction application at a power plant in Chile. The unit is 8″ in diameter with an overall length of 82″. The bellows were fabricated from 321 stainless steel with the weld ends and tie rods from carbon steel. The expansion joint is designed for an operating pressure of 145 psig at 678°F with 1.25″ of lateral deflection. All welds were 100% dye-penetrant examined and hydrotested prior to shipment.

U.S. Bellows custom designed this universal expansion joint for a steam line extraction application at a power plant in Chile. The unit is 8″ in diameter with an overall length of 82″. The bellows were fabricated from 321 stainless steel with the weld ends and tie rods from carbon steel. The expansion joint is designed for an operating pressure of 145 psig at 678°F with 1.25″ of lateral deflection. All welds were 100% dye-penetrant examined and hydrotested prior to shipment.

Read More

| Type: |

Single Expansion Joint |

| Size: |

8″ Diameter and 7 1/8″ overall length |

| Material: |

304 Stainless Steel |

| Design |

160°F at 55 psig with 1/2″ of axil movement |

| Testing: |

100% Dye Penetrant | Hydro-tested |

U.S. Bellows custom designed these single expansion joint for a power plant in Mississippi. They are 8″ in diameter and 7 1/8″ overall length. The bellows were fabricated from 304 stainless steel and the flanges from carbon steel. The interior surface of the units were coated with PTFE. The expansion joints were designed for an operating temperature of 160°F at 55 psig with 1/2″ of axial movement. All unites were 100% dye-penetrant and hydro-tested prior to shipment.

| Type: |

Single Expansion Joint |

| Size: |

8″ Diameter and 7 1/8″ overall length |

| Material: |

304 Stainless Steel |

| Design |

160°F at 55 psig with 1/2″ of axil movement |

| Testing: |

100% Dye Penetrant | Hydro-tested |

U.S. Bellows custom designed these single expansion joint for a power plant in Mississippi. They are 8″ in diameter and 7 1/8″ overall length. The bellows were fabricated from 304 stainless steel and the flanges from carbon steel. The interior surface of the units were coated with PTFE. The expansion joints were designed for an operating temperature of 160°F at 55 psig with 1/2″ of axial movement. All unites were 100% dye-penetrant and hydro-tested prior to shipment.

Read More

U.S. Bellows custom designed this tied universal expansion joint with floating flanges for a sulphur line application at a chemical facility in British Columbia, Canada. The expansion joint is 48″ in diameter and 72-1/2″ in length. The bellows is fabricated from 304 wetted stainless steel and the flanges and hardware from carbon steel. It is designed for an operating pressure of 10 pisg at 600°F with 1.8″ of axial compression. The unit was 100% dye- penetrant and pressure tested prior to shipment.

U.S. Bellows custom designed this tied universal expansion joint with floating flanges for a sulphur line application at a chemical facility in British Columbia, Canada. The expansion joint is 48″ in diameter and 72-1/2″ in length. The bellows is fabricated from 304 wetted stainless steel and the flanges and hardware from carbon steel. It is designed for an operating pressure of 10 pisg at 600°F with 1.8″ of axial compression. The unit was 100% dye- penetrant and pressure tested prior to shipment.

Read More

US Bellows custom-designed these externally pressurized expansion joints for a pipeline in Kentucky. The bellows are fabricated from Inconel 625 LCF and all other components from carbon steel. The expansion joints are 4″ in diameter and 32″ OAL. They are designed for an operating pressure of 135 PSIG at 358°F with 3″ of compression. All expansion joints were hydro-tested prior to shipment. Externally pressurized expansion joints are suited for piping systems that require large amounts of axial compression or extension. In externally pressurized expansion joints, the bellows elements are arranged so that the media flow is on the external surface of the bellows. Externally pressurizing the bellows eliminates pressure instability as a limitation to the design and permits the absorption of large amounts of axial expansion.

US Bellows custom-designed these externally pressurized expansion joints for a pipeline in Kentucky. The bellows are fabricated from Inconel 625 LCF and all other components from carbon steel. The expansion joints are 4″ in diameter and 32″ OAL. They are designed for an operating pressure of 135 PSIG at 358°F with 3″ of compression. All expansion joints were hydro-tested prior to shipment. Externally pressurized expansion joints are suited for piping systems that require large amounts of axial compression or extension. In externally pressurized expansion joints, the bellows elements are arranged so that the media flow is on the external surface of the bellows. Externally pressurizing the bellows eliminates pressure instability as a limitation to the design and permits the absorption of large amounts of axial expansion.

Read More