| Type: |

Single Hinged Expansion Joints |

| Size: |

64″ length x 127″ diameter |

| Material: |

Carbon Steel and 304 Stainless Steel |

| Design |

Operating Temperature Range: -10°F to 121°F

Pressure: 15 PSIG

Movement: 0.6° of Angular Rotation |

| Testing: |

100% Dye Penetrant Test | Vaccum tested at 28.5″ of Mercury | 100% X-Rayed. |

U.S. Bellows custom designed Single Hinged Expansion Joints for vacuum service in high-velocity steam and condensate duct for an air-cooled condenser unit in New York. The bellows are fabricated from a 304 stainless steel. The weld-ends and hardware are fabricated from carbon steel. The units are 127″ in diameter and 64″ overall length. They are designed for an operating pressure at full vacuum to 15 psi at -10 to 121°F and 0.6° of angular rotation. The units were vacuum tested at 28.5″ of mercury, 100% dye-penetrant examined, and the bellows longitudinal seams were 100% X-rayed.

| Type: |

Single Hinged Expansion Joints |

| Size: |

64″ length x 127″ diameter |

| Material: |

Carbon Steel and 304 Stainless Steel |

| Design |

Operating Temperature Range: -10°F to 121°F

Pressure: 15 PSIG

Movement: 0.6° of Angular Rotation |

| Testing: |

100% Dye Penetrant Test | Vaccum tested at 28.5″ of Mercury | 100% X-Rayed. |

U.S. Bellows custom designed Single Hinged Expansion Joints for vacuum service in high-velocity steam and condensate duct for an air-cooled condenser unit in New York. The bellows are fabricated from a 304 stainless steel. The weld-ends and hardware are fabricated from carbon steel. The units are 127″ in diameter and 64″ overall length. They are designed for an operating pressure at full vacuum to 15 psi at -10 to 121°F and 0.6° of angular rotation. The units were vacuum tested at 28.5″ of mercury, 100% dye-penetrant examined, and the bellows longitudinal seams were 100% X-rayed.

Read More

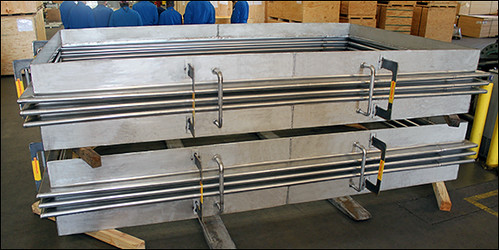

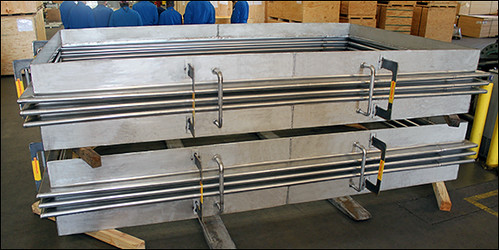

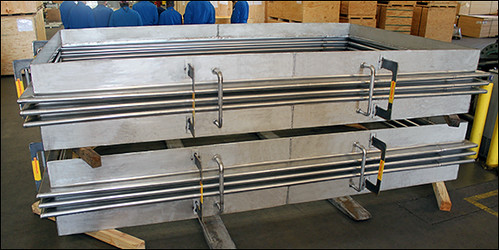

| Type: |

Rectangular metallic Universal Expansion Joint |

| Size: |

291.75″ long x 62″ wide x 76″ high |

| Design: |

Operating Temperature Range: 850°F

Pressure: 1.5 PSIG

Movement: 1.5″ Axial Compression |

| Material: |

A36 Carbon Steel and 304 Stainless Steel |

| Testing: |

100% Dye Penetrant Test and Pneumatic Test |

U.S. Bellows custom designed this universal rectangular expansion joint for a steam turbine facility in Alaska. The bellows and liner were fabricated from 304 stainless steel and the weld ends from A36 carbon steel. The unit is 62″ wide, 291.75″ in length, and 76″ in height. It is designed for an operating temperature up to 850°F at 1.5 psig and 1.5″ of axial compression. The expansion joint was 100% dye-penetrant tested and pneumatic tested prior to shipment.

| Type: |

Rectangular metallic Universal Expansion Joint |

| Size: |

291.75″ long x 62″ wide x 76″ high |

| Design: |

Operating Temperature Range: 850°F

Pressure: 1.5 PSIG

Movement: 1.5″ Axial Compression |

| Material: |

A36 Carbon Steel and 304 Stainless Steel |

| Testing: |

100% Dye Penetrant Test and Pneumatic Test |

U.S. Bellows custom designed this universal rectangular expansion joint for a steam turbine facility in Alaska. The bellows and liner were fabricated from 304 stainless steel and the weld ends from A36 carbon steel. The unit is 62″ wide, 291.75″ in length, and 76″ in height. It is designed for an operating temperature up to 850°F at 1.5 psig and 1.5″ of axial compression. The expansion joint was 100% dye-penetrant tested and pneumatic tested prior to shipment.

Read More

| Type: |

Rubber Expansion Joint |

| Size: |

59.5″ x 20.25″ x 14″ FTF | 29.875″ x 22.75″ x 14″ FTF |

| Design: |

Viton Rubber | 304 Stainless Steel | Carbon Steel |

| Material: |

250°F, 5 psig, & 0.25″ Axial & Lateral |

| Testing: |

Hydro-tested at 5 psig |

These rectangular Viton rubber expansion joints were custom designed for a suction and centrifuge discharge of paraxylene application at a chemical plant in India. The units are 59.5″ x 20.25″ x 14″ face-to-face and 29.875″ x 22.75″ x 14″ face-to-face. The belt material is made from Viton rubber with 304 stainless steel liner and carbon steel retaining bars. They are designed for an operating temperature up to 250°F at 5 psig, with 0.25″ of axial compression and lateral deflection. The units were hydro-tested to 5 psig prior to shipment.

| Type: |

Rubber Expansion Joint |

| Size: |

59.5″ x 20.25″ x 14″ FTF | 29.875″ x 22.75″ x 14″ FTF |

| Design: |

Viton Rubber | 304 Stainless Steel | Carbon Steel |

| Material: |

250°F, 5 psig, & 0.25″ Axial & Lateral |

| Testing: |

Hydro-tested at 5 psig |

These rectangular Viton rubber expansion joints were custom designed for a suction and centrifuge discharge of paraxylene application at a chemical plant in India. The units are 59.5″ x 20.25″ x 14″ face-to-face and 29.875″ x 22.75″ x 14″ face-to-face. The belt material is made from Viton rubber with 304 stainless steel liner and carbon steel retaining bars. They are designed for an operating temperature up to 250°F at 5 psig, with 0.25″ of axial compression and lateral deflection. The units were hydro-tested to 5 psig prior to shipment.

Read More

| Type: |

Single Flanged Expansion Joint |

| Size: |

41 3/8″ Length | 56.3″-76.75″ Diameter |

| Material: |

Incoloy 800 | 304H Stainless Steel |

| Design |

1231°F | 15 psig | 2.624″ Axial & 0.25″ Lateral |

| Testing: |

Radiographic | Dye-penetrant | Hydro-tested at 23 psig |

U.S. Bellows custom designed these single expansion joints for a pipeline in China. All units are 41 3/8″ length and vary in diameter from 56.3″-76.75″. The bellows were fabricated from Incoloy 800 and the weld ends from 304H stainless steel. They are designed for an operating pressure of 15 psig at 1231°F with 2.624″ axial compression and 0.25″ lateral deflection. The bellows and weld ends were 100% radiographic tested, 100% dye-penetrant tested, and hydro-tested at 23 psig prior to shipment

| Type: |

Single Flanged Expansion Joint |

| Size: |

41 3/8″ Length | 56.3″-76.75″ Diameter |

| Material: |

Incoloy 800 | 304H Stainless Steel |

| Design |

1231°F | 15 psig | 2.624″ Axial & 0.25″ Lateral |

| Testing: |

Radiographic | Dye-penetrant | Hydro-tested at 23 psig |

U.S. Bellows custom designed these single expansion joints for a pipeline in China. All units are 41 3/8″ length and vary in diameter from 56.3″-76.75″. The bellows were fabricated from Incoloy 800 and the weld ends from 304H stainless steel. They are designed for an operating pressure of 15 psig at 1231°F with 2.624″ axial compression and 0.25″ lateral deflection. The bellows and weld ends were 100% radiographic tested, 100% dye-penetrant tested, and hydro-tested at 23 psig prior to shipment

Read More

| Type: |

Neoprene Expansion Joint |

| Size: |

153″ x 55″ x 21″ |

| Design: |

EPDM Reinforced Fabric Cloth | Carbon Steel |

| Material: |

200°F, +/- 100″ WC, & 1″ Axial |

| Testing: |

Hydro-tested |

This EPDM neoprene expansion joint was designed for an air recirculation/ventilation application at a gas turbine facility in Hungary by U.S. Bellows. The unit is 153″ in length x 55″ width x 21″ face-to-face. The fabric belt is made from EPDM reinforced fabric cloth and the framework from A572 Gr. 50 carbon steel. It is designed for an operating temperature up to 200°F with a +/- 100″ water column and 1″ of axial compression and lateral deflection. The expansion joint was hydro-tested prior to shipment.

| Type: |

Neoprene Expansion Joint |

| Size: |

153″ x 55″ x 21″ |

| Design: |

EPDM Reinforced Fabric Cloth | Carbon Steel |

| Material: |

200°F, +/- 100″ WC, & 1″ Axial |

| Testing: |

Hydro-tested |

This EPDM neoprene expansion joint was designed for an air recirculation/ventilation application at a gas turbine facility in Hungary by U.S. Bellows. The unit is 153″ in length x 55″ width x 21″ face-to-face. The fabric belt is made from EPDM reinforced fabric cloth and the framework from A572 Gr. 50 carbon steel. It is designed for an operating temperature up to 200°F with a +/- 100″ water column and 1″ of axial compression and lateral deflection. The expansion joint was hydro-tested prior to shipment.

Read More

| Type: |

In-line Pressure Balanced Expansion Joint |

| Size: |

16″ Dia. & 59″ OAL |

| Design: |

304 Stainless Steel | Carbon Steel |

| Material: |

248°F at 86 psig & 2.5″ Axial |

| Testing: |

Hydro-tested & 100% Dye-Penetrant |

U.S. Bellows custom designed this in-line pressure balanced expansion joint for an oil refinery in India. The unit is 16″ in diameter and 59″ overall length. The bellows were fabricated from 304 stainless steel and the remaining parts from carbon steel. It is designed for an operating temperature of 248°F at 86 psig with 2.5″ of axial compression. The expansion joint was 100% dye-penetrant tested and hydro-tested prior to shipment.

| Type: |

In-line Pressure Balanced Expansion Joint |

| Size: |

16″ Dia. & 59″ OAL |

| Design: |

304 Stainless Steel | Carbon Steel |

| Material: |

248°F at 86 psig & 2.5″ Axial |

| Testing: |

Hydro-tested & 100% Dye-Penetrant |

U.S. Bellows custom designed this in-line pressure balanced expansion joint for an oil refinery in India. The unit is 16″ in diameter and 59″ overall length. The bellows were fabricated from 304 stainless steel and the remaining parts from carbon steel. It is designed for an operating temperature of 248°F at 86 psig with 2.5″ of axial compression. The expansion joint was 100% dye-penetrant tested and hydro-tested prior to shipment.

Read More

| Type: |

Universal Expansion Joint |

| Size: |

8″ x 16″ FTF | 24″ OAL |

| Design: |

316 Stainless Steel | Carbon Steel |

| Material: |

185°F at 264 psig & 2.75″ Lateral |

| Testing: |

Hydro-tested at 395 psig & 100% Dye-Penetrant |

These universal expansion joints were designed for fuel tank farm in Saudi Arabia. The units are 8″ x 16″ face-to-face and 24″ OAL. The bellows were fabricated from 316 stainless steel and the rest of the unit from carbon steel, with a custom 3-layer paint coat. They are designed for an operating temperature of 185°F at 264 psig and 2.75″ of lateral deflection. The expansion joints were 100% dye-penetrant tested and hydro-tested at 395 psig prior to shipments.

| Type: |

Universal Expansion Joint |

| Size: |

8″ x 16″ FTF | 24″ OAL |

| Design: |

316 Stainless Steel | Carbon Steel |

| Material: |

185°F at 264 psig & 2.75″ Lateral |

| Testing: |

Hydro-tested at 395 psig & 100% Dye-Penetrant |

These universal expansion joints were designed for fuel tank farm in Saudi Arabia. The units are 8″ x 16″ face-to-face and 24″ OAL. The bellows were fabricated from 316 stainless steel and the rest of the unit from carbon steel, with a custom 3-layer paint coat. They are designed for an operating temperature of 185°F at 264 psig and 2.75″ of lateral deflection. The expansion joints were 100% dye-penetrant tested and hydro-tested at 395 psig prior to shipments.

Read More

| Type: |

Rectangular Expansion Joint |

| Size: |

91″ x 130″ x 24″ |

| Design: |

304 Stainless Steel |

| Material: |

482°F at 14.2 psig & 1″ Axial Compression |

| Testing: |

Soap & Air and 100% Dye-Penetrant |

These rectangular expansion joints was custom designed by U.S. Bellows for a chemical plant in Texas. It has dimensions of 91″ x 130″ x 24″. It was completely fabricated from 304 stainless steel. The units are designed for an operating temperature of 482°F with an operating pressure of 14.2 psig and 1″ of axial compression. The expansion joints were soap & air tested and 100% dye penetrant tested prior to shipment.

| Type: |

Rectangular Expansion Joint |

| Size: |

91″ x 130″ x 24″ |

| Design: |

304 Stainless Steel |

| Material: |

482°F at 14.2 psig & 1″ Axial Compression |

| Testing: |

Soap & Air and 100% Dye-Penetrant |

These rectangular expansion joints was custom designed by U.S. Bellows for a chemical plant in Texas. It has dimensions of 91″ x 130″ x 24″. It was completely fabricated from 304 stainless steel. The units are designed for an operating temperature of 482°F with an operating pressure of 14.2 psig and 1″ of axial compression. The expansion joints were soap & air tested and 100% dye penetrant tested prior to shipment.

Read More

| Type: |

Single Expansion Joint |

| Size: |

39″ Dia. | 24″ OAL |

| Material: |

304 Stainless Steel | CS |

| Design |

400°F at 35 psig & 2″ Axial Compression |

| Testing: |

100% Hydro-tested at 57 psig |

U.S. Bellows designed this single metallic expansion joint for a chemical plant in Texas. The unit has a 39″ diameter and is 24″ overall length. The bellows were fabricated from 304 stainless steel with carbon steel flanges. It is designed for an operating temperature up to 400°F at 35 psig, with 22″ of axial compression. The expansion joint was hydro-tested at 57 psig prior to shipment.

| Type: |

Single Expansion Joint |

| Size: |

39″ Dia. | 24″ OAL |

| Material: |

304 Stainless Steel | CS |

| Design |

400°F at 35 psig & 2″ Axial Compression |

| Testing: |

100% Hydro-tested at 57 psig |

U.S. Bellows designed this single metallic expansion joint for a chemical plant in Texas. The unit has a 39″ diameter and is 24″ overall length. The bellows were fabricated from 304 stainless steel with carbon steel flanges. It is designed for an operating temperature up to 400°F at 35 psig, with 22″ of axial compression. The expansion joint was hydro-tested at 57 psig prior to shipment.

Read More

| Type: |

Universal Expansion Joint |

| Size: |

118″ CL-to-CL, 132 3/8″ FTF, & 24″ OD |

| Material: |

304 Stainless Steel/Carbon Steel |

| Design: |

400°F at 310 PSIG & 1 1/8″ Lateral Movement |

| Testing: |

Dye-Penetrant, PMI, X-Ray, and Hydrotested at 465 PSIG |

US Bellows custom-designed 2 of these tied double elbow universal expansion joints for a liquid hydrocarbon service application at a paraxylene complex in Saudi Arabia. The bellows were fabricated from 304 stainless steel, and the piping and hardware from carbon steel and have a 3-coat paint system. The unit is 118″ CL-to-CL of the elbow, 132 3/8″ face-to-face, and 24″ OD. It was designed for an operating pressure of 310 PSIG at 400°F with 1 1/8″ of lateral deflection. The unit was hydro-tested at 465 psi, x-ray tested the bellows long seam and pipe, PMI all alloys, and 100% dye-penetrant tested on all welds prior to shipment

| Type: |

Universal Expansion Joint |

| Size: |

118″ CL-to-CL, 132 3/8″ FTF, & 24″ OD |

| Material: |

304 Stainless Steel/Carbon Steel |

| Design: |

400°F at 310 PSIG & 1 1/8″ Lateral Movement |

| Testing: |

Dye-Penetrant, PMI, X-Ray, and Hydrotested at 465 PSIG |

US Bellows custom-designed 2 of these tied double elbow universal expansion joints for a liquid hydrocarbon service application at a paraxylene complex in Saudi Arabia. The bellows were fabricated from 304 stainless steel, and the piping and hardware from carbon steel and have a 3-coat paint system. The unit is 118″ CL-to-CL of the elbow, 132 3/8″ face-to-face, and 24″ OD. It was designed for an operating pressure of 310 PSIG at 400°F with 1 1/8″ of lateral deflection. The unit was hydro-tested at 465 psi, x-ray tested the bellows long seam and pipe, PMI all alloys, and 100% dye-penetrant tested on all welds prior to shipment

Read More

| Type: |

Universal Hinged Expansion Joint |

| Size: |

86″ Height, 234″ Long, & 42″ OD |

| Material: |

Inconel 625/Chrome-Moly/Carbon Steel |

| Design |

1025°F at 45 psig, 3/4″ of Axial, & 12.5″ of lateral |

| Testing: |

100% Radiographic Examined, Pneumatic Tested at 61 psi, Leak Tested at 51 psig, & Dye-Penetrant |

U.S. Bellows custom fabricated this universal hinged expansion joint with oversized bellows, movement indicators, and test ports, in less than 12 weeks for a refinery turnaround in Texas. The unit is 86″ in height, 234″ long, and has a 42″ OD. The bellows were fabricated from Inconel 625, the piping from chrome-moly, the hinge hardware from carbon steel, and the covers from 304 stainless steel. It is designed for an operating temperature of 1025°F at 45 psig, with 3/4″ of axial compression and 12.5″ of lateral deflection. The unit was post-weld heat treatment and 100% radiographic examined the circumferential and long seams after the post-weld heat treatment, plus pneumatically tested at 61 psi, the bellows were leak tested to 15 psig between the plies, and dye-penetrant tested prior to shipment.

| Type: |

Universal Hinged Expansion Joint |

| Size: |

86″ Height, 234″ Long, & 42″ OD |

| Material: |

Inconel 625/Chrome-Moly/Carbon Steel |

| Design |

1025°F at 45 psig, 3/4″ of Axial, & 12.5″ of lateral |

| Testing: |

100% Radiographic Examined, Pneumatic Tested at 61 psi, Leak Tested at 51 psig, & Dye-Penetrant |

U.S. Bellows custom fabricated this universal hinged expansion joint with oversized bellows, movement indicators, and test ports, in less than 12 weeks for a refinery turnaround in Texas. The unit is 86″ in height, 234″ long, and has a 42″ OD. The bellows were fabricated from Inconel 625, the piping from chrome-moly, the hinge hardware from carbon steel, and the covers from 304 stainless steel. It is designed for an operating temperature of 1025°F at 45 psig, with 3/4″ of axial compression and 12.5″ of lateral deflection. The unit was post-weld heat treatment and 100% radiographic examined the circumferential and long seams after the post-weld heat treatment, plus pneumatically tested at 61 psi, the bellows were leak tested to 15 psig between the plies, and dye-penetrant tested prior to shipment.

Read More

| Type: |

Single Expansion Joint |

| Size: |

13.5″ Diameter & 6″ OAL |

| Material: |

304 Stainless Steel | CS |

| Design |

300°F at 85 psig 1″ Axil & 0.10″ Lateral |

| Testing: |

100% Hydro-tested |

U.S. Bellows, Inc. designed these single expansion joints for a pipeline in Louisiana. The expansion joints are 13.5″ in diameter and 6″ OAL. The bellows and liner are fabricated from 304L stainless steel and the flanges from carbon steel. The expansion joints were designed for a temperature of 300°F at 85 psig with 1″ of axial compression and 0.10″ of lateral deflection. All expansion joints were hydro-tested prior to shipment.

| Type: |

Single Expansion Joint |

| Size: |

13.5″ Diameter & 6″ OAL |

| Material: |

304 Stainless Steel | CS |

| Design |

300°F at 85 psig 1″ Axil & 0.10″ Lateral |

| Testing: |

100% Hydro-tested |

U.S. Bellows, Inc. designed these single expansion joints for a pipeline in Louisiana. The expansion joints are 13.5″ in diameter and 6″ OAL. The bellows and liner are fabricated from 304L stainless steel and the flanges from carbon steel. The expansion joints were designed for a temperature of 300°F at 85 psig with 1″ of axial compression and 0.10″ of lateral deflection. All expansion joints were hydro-tested prior to shipment.

Read More

| Type: |

Rectangular Expansion Joint |

| Size: |

148″ x 148″ and 17″ FTF |

| Design: |

316 Stainless Steel |

| Material: |

350°F at +50″ water column and 1.5″ Axial |

| Testing: |

100% Dye-Penetrant and Air & Soap |

This rectangular metallic expansion joint was custom engineered for an oil refinery in Texas. The unit’s dimensions are 148″ x 148″ and 17″ face-to-face length. The bellows, flanges, and hardware were completely fabricated from 316 stainless steel. It is designed for an operating temperature of 350°F at +50″ water column and 1.5″ of axial compression. The unit was 100% dye-penetrant and air & soap tested prior to shipment.

| Type: |

Rectangular Expansion Joint |

| Size: |

148″ x 148″ and 17″ FTF |

| Design: |

316 Stainless Steel |

| Material: |

350°F at +50″ water column and 1.5″ Axial |

| Testing: |

100% Dye-Penetrant and Air & Soap |

This rectangular metallic expansion joint was custom engineered for an oil refinery in Texas. The unit’s dimensions are 148″ x 148″ and 17″ face-to-face length. The bellows, flanges, and hardware were completely fabricated from 316 stainless steel. It is designed for an operating temperature of 350°F at +50″ water column and 1.5″ of axial compression. The unit was 100% dye-penetrant and air & soap tested prior to shipment.

Read More

| Type: |

Universal Expansion Joint |

| Size: |

118″ CL-to-CL, 132 3/8″ FTF, & 24″ OD |

| Material: |

304 Stainless Steel/Carbon Steel |

| Design: |

400°F at 310 psig & 1 1/8″ Lateral Movement |

| Testing: |

Dye-Penetrant, PMI, X-Ray, and Hydrotested at 465 psig |

U.S. Bellows custom designed 8 of these 335″ long universal expansion joints for a vacuum ducting service, exposed to high velocity steam and condensate for an ACC unit in New York. The bellows were completely fabricated from 304 stainless steel, with the weld-ends and hardware from carbon steel. The units are 127″ in diameter and 335″ in length. They are designed for an operating pressure at full vacuum to 15 psi at -10 to 250°F and 7.25″ of lateral deflection. The units were vacuum tested at 28.5″ of mercury, 100% dye-penetrant examined, and X-ray long seam bellows.

This expansion joint was featured in our lastest Technical Bulletin:

Click here to learn more about air-cooled condenser expansion joint

| Type: |

Universal Expansion Joint |

| Size: |

118″ CL-to-CL, 132 3/8″ FTF, & 24″ OD |

| Material: |

304 Stainless Steel/Carbon Steel |

| Design: |

400°F at 310 psig & 1 1/8″ Lateral Movement |

| Testing: |

Dye-Penetrant, PMI, X-Ray, and Hydrotested at 465 psig |

U.S. Bellows custom designed 8 of these 335″ long universal expansion joints for a vacuum ducting service, exposed to high velocity steam and condensate for an ACC unit in New York. The bellows were completely fabricated from 304 stainless steel, with the weld-ends and hardware from carbon steel. The units are 127″ in diameter and 335″ in length. They are designed for an operating pressure at full vacuum to 15 psi at -10 to 250°F and 7.25″ of lateral deflection. The units were vacuum tested at 28.5″ of mercury, 100% dye-penetrant examined, and X-ray long seam bellows.

This expansion joint was featured in our lastest Technical Bulletin:

Click here to learn more about air-cooled condenser expansion joint

Read More

| Type: |

Externally Pressurized Expansion Joints |

| Size: |

4″ Diameter & 57″ Length |

| Design: |

304 Stainless Steel |

| Material: |

500°F at 30 psig, 189 lb./in. Spring Rate & 8″ Axial |

| Testing: |

Dye-Penetrant and Air Soap & Bubble |

U.S. Bellows custom designed these externally pressurized expansion joints for pneumatic conveying and filtration at a manufacturing facility in Missouri. The units were completely fabricated for 304 stainless steel. They are 4″ in diameter and 57″ in length. These expansion joints are designed for an operating temperature or 500°F at 30 psig, with a spring rate of 189 lb./in. and can absorb 8″ of axial compression. The units were 100% dye-penetrant and air soap & bubble tested prior to shipment.

| Type: |

Externally Pressurized Expansion Joints |

| Size: |

4″ Diameter & 57″ Length |

| Design: |

304 Stainless Steel |

| Material: |

500°F at 30 psig, 189 lb./in. Spring Rate & 8″ Axial |

| Testing: |

Dye-Penetrant and Air Soap & Bubble |

U.S. Bellows custom designed these externally pressurized expansion joints for pneumatic conveying and filtration at a manufacturing facility in Missouri. The units were completely fabricated for 304 stainless steel. They are 4″ in diameter and 57″ in length. These expansion joints are designed for an operating temperature or 500°F at 30 psig, with a spring rate of 189 lb./in. and can absorb 8″ of axial compression. The units were 100% dye-penetrant and air soap & bubble tested prior to shipment.

Read More

| Type: |

EPDM Rubber Expansion Joints |

| Size: |

9″ Diameter & 10″ Face-To-Face |

| Design: |

EPDM Rubber/Carbon Steel |

| Material: |

250°F at 225 psig, 3.5″ Axial Compression & 1.5″ Lateral Deflection |

| Testing: |

Hydro tested |

U.S. Bellows furnished these EPDM rubber expansion joints for a water cooling loop at a chemical plant in Saudi Arabia. The bellows are twin-open arch EPDM rubber and have a set of galvanized carbon steel retaining rings. The units are 10″ face-to-face and 9″ in diameter. They are designed for an operating temperature of 250°F at 225 psig with 3.5″ of axial compression, 1.5″ of lateral deflection, and 4° of angular rotation. The units were hydro tested at 1.5 times their design pressure prior to shipment.

| Type: |

EPDM Rubber Expansion Joints |

| Size: |

9″ Diameter & 10″ Face-To-Face |

| Design: |

EPDM Rubber/Carbon Steel |

| Material: |

250°F at 225 psig, 3.5″ Axial Compression & 1.5″ Lateral Deflection |

| Testing: |

Hydro tested |

U.S. Bellows furnished these EPDM rubber expansion joints for a water cooling loop at a chemical plant in Saudi Arabia. The bellows are twin-open arch EPDM rubber and have a set of galvanized carbon steel retaining rings. The units are 10″ face-to-face and 9″ in diameter. They are designed for an operating temperature of 250°F at 225 psig with 3.5″ of axial compression, 1.5″ of lateral deflection, and 4° of angular rotation. The units were hydro tested at 1.5 times their design pressure prior to shipment.

Read More

| Type: |

Universal Expansion Joint |

| Size: |

118″ CL-to-CL, 132 3/8″ FTF, & 24″ OD |

| Material: |

304 Stainless Steel/Carbon Steel |

| Design: |

400°F at 310 psig & 1 1/8″ Lateral Movement |

| Testing: |

Dye-Penetrant, PMI, X-Ray, and Hydrotested at 465 psig |

This tied universal expansion joint was designed by U.S. Bellows for a pipeline in the UAE. The unit is 24″ in diameter and 106″ in length. The bellows are fabricated from 304 stainless steel and the rest of the components from carbon steel. It is designed for an operating pressure of 15 psig at 194°F with an operating load of 501 lb/in. and 6″ of lateral deflection. The unit was 100% LP tested, X-ray examined, and hydro tested prior to shipment

| Type: |

Universal Expansion Joint |

| Size: |

118″ CL-to-CL, 132 3/8″ FTF, & 24″ OD |

| Material: |

304 Stainless Steel/Carbon Steel |

| Design: |

400°F at 310 psig & 1 1/8″ Lateral Movement |

| Testing: |

Dye-Penetrant, PMI, X-Ray, and Hydrotested at 465 psig |

This tied universal expansion joint was designed by U.S. Bellows for a pipeline in the UAE. The unit is 24″ in diameter and 106″ in length. The bellows are fabricated from 304 stainless steel and the rest of the components from carbon steel. It is designed for an operating pressure of 15 psig at 194°F with an operating load of 501 lb/in. and 6″ of lateral deflection. The unit was 100% LP tested, X-ray examined, and hydro tested prior to shipment

Read More

| Type: |

Double Gimbal Expansion Joints |

| Size: |

30″ Diameter | 198″ Length |

| Material: |

2-Ply Bellows: Inconel 625 LCF | Pipes: 316 H SS | Covers & Liners: CS |

| Design: |

5° Angular Rotation | 1260°F | 180 psig |

| Testing: |

100% Dye-Penetrant | PMI Examined | Hydro-tested |

U.S. Bellows custom designed and fabricated double gimbal expansion joints for a chemical plant in Arkansas. The assemblies are designed with 2-ply bellows which were fabricated from Inconel 625 LCF. The pipes are 316 H stainless steel and the covers and liners are carbon steel. The units are 30″ in diameter and have an overall length of 198″. The expansion joints were designed for 5° angular rotation at 1260°F and 180 psig. Prior to shipment, the units were 100% dye penetrant tested, PMI examined, and hydro-tested.

| Type: |

Double Gimbal Expansion Joints |

| Size: |

30″ Diameter | 198″ Length |

| Material: |

2-Ply Bellows: Inconel 625 LCF | Pipes: 316 H SS | Covers & Liners: CS |

| Design: |

5° Angular Rotation | 1260°F | 180 psig |

| Testing: |

100% Dye-Penetrant | PMI Examined | Hydro-tested |

U.S. Bellows custom designed and fabricated double gimbal expansion joints for a chemical plant in Arkansas. The assemblies are designed with 2-ply bellows which were fabricated from Inconel 625 LCF. The pipes are 316 H stainless steel and the covers and liners are carbon steel. The units are 30″ in diameter and have an overall length of 198″. The expansion joints were designed for 5° angular rotation at 1260°F and 180 psig. Prior to shipment, the units were 100% dye penetrant tested, PMI examined, and hydro-tested.

Read More

| Type: |

Neoprene & Fabric Expansion Joints |

| Size: |

59″ Dia./7″ face-to-face & 136″ x 54″ x 12″. |

| Material: |

Fabric Reinforced Neoprene/Carbon Steel & PTFE Fabric Belt/304 Stainless Steel |

| Design: |

-20°F-600°F with +/- 100″ water column, 1/2″ of Axial & Lateral |

| Testing: |

100% Dye-Penetrant |

These neoprene and fabric expansion joints were designed by U.S. Bellows for an exhaust duct application at a gas turbine facility in Hungary. The rounds are 59″ in diameter and 7″ face-to-face, and the rectangular is 136″ x 54″ x 12″. The rounds are fabricated from A572 Gr50 carbon steel with fabric reinforced neoprene belts and the rectangular has a PTFE fabric belt with 304 stainless steel framework. They are designed for an operating temperature from -20°F-600°F with +/- 100″ water column and 1/2″ of axial compression and lateral deflection. A dye-penetrant examination was conducted on the unit prior to shipment.

| Type: |

Neoprene & Fabric Expansion Joints |

| Size: |

59″ Dia./7″ face-to-face & 136″ x 54″ x 12″. |

| Material: |

Fabric Reinforced Neoprene/Carbon Steel & PTFE Fabric Belt/304 Stainless Steel |

| Design: |

-20°F-600°F with +/- 100″ water column, 1/2″ of Axial & Lateral |

| Testing: |

100% Dye-Penetrant |

These neoprene and fabric expansion joints were designed by U.S. Bellows for an exhaust duct application at a gas turbine facility in Hungary. The rounds are 59″ in diameter and 7″ face-to-face, and the rectangular is 136″ x 54″ x 12″. The rounds are fabricated from A572 Gr50 carbon steel with fabric reinforced neoprene belts and the rectangular has a PTFE fabric belt with 304 stainless steel framework. They are designed for an operating temperature from -20°F-600°F with +/- 100″ water column and 1/2″ of axial compression and lateral deflection. A dye-penetrant examination was conducted on the unit prior to shipment.

Read More

| Type: |

Rectangular Expansion Joint |

| Size: |

107″ x 71″ x 64″ |

| Design: |

304 Stainless Steel and Carbon Steel |

| Material: |

250°F at 15 PSIG and 0.125″ of lateral deflection |

| Testing: |

Soap & Air, 100% Dye-Penetant, and Pneumatic |

This rectangular expansion joint was custom fabricated by U.S. Bellows for a refinery in Texas. The expansion joint is 107″ in height, 71″ in width, and 64″ in length. The bellows and cover were fabricated from 304 stainless steel and the rest of the components from carbon steel. It is designed for 250°F at 15 PSIG and 0.125″ of lateral deflection. The expansion joint was soap & air, 100% dye-penetrant, and pneumatic tested prior to shipment.

| Type: |

Rectangular Expansion Joint |

| Size: |

107″ x 71″ x 64″ |

| Design: |

304 Stainless Steel and Carbon Steel |

| Material: |

250°F at 15 PSIG and 0.125″ of lateral deflection |

| Testing: |

Soap & Air, 100% Dye-Penetant, and Pneumatic |

This rectangular expansion joint was custom fabricated by U.S. Bellows for a refinery in Texas. The expansion joint is 107″ in height, 71″ in width, and 64″ in length. The bellows and cover were fabricated from 304 stainless steel and the rest of the components from carbon steel. It is designed for 250°F at 15 PSIG and 0.125″ of lateral deflection. The expansion joint was soap & air, 100% dye-penetrant, and pneumatic tested prior to shipment.

Read More