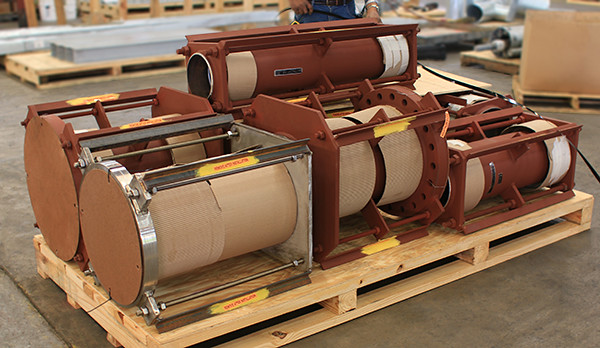

These universal expansion joints were custom-designed with guided tie rods, internal liners, and bellows protection covers for a hot air blower. These expansion joints are used in a plant that manufactures tires for cars and light-duty trucks. High Heat is required in the manufacturing process to vulcanize rubber to components made of steel and polyester and to also cure the rubber. The universal expansion joint can allow for large amounts of lateral deflection that can occur in more than one plane. By increasing or decreasing the distance between the two bellows by varying the length of a section of pipe spool, the designer can accommodate for the given amount of lateral deflection. These expansion joints are designed for an operating pressure of 50 psig at 383 degrees F. A total of 18 were supplied with half of the units measuring 40” dia. x 74-7/8” long x 58-1/2” overall outer dia. The rest measure 36” dia. X 60-1/4” long x 53-3/4” overall outer diameter. The bellows, flange, middle pipe, liner, and lugs are fabricated from 316/316L stainless steel. The rods, nuts, and cover are 316 stainless steel. The 40” dia. unit is designed for 0.394” axial compression and the 36” dia. unit is designed for 0.20” axial compression. Both units are designed for 0.394” lateral movement. Each expansion joint was inspected by quality control and hydraulic pressure tested before shipment. We manufacture expansion joints to relieve stress in piping systems whether the thermal movement is axial, lateral, or angular in plants such as Food Processing, Automotive, Hospital Steam Lines, Semiconductors, and other types of Green Energy plants.

Read MoreFeatured Product Archives

Rubber Expansion Joints for a 24″ Dia. Pipeline at an Offshore Production Facility

U.S. Bellows provided rubber expansion joints for a 24” diameter pipeline at an offshore production facility. Used near rotating equipment such as pumps and compressors, rubber expansion joints provide a viable alternative when metal joints cannot be used. Expansion joints can be used in plants such as biofuels green energy that utilize trash/waste as feedstock help to reduce greenhouse gas emissions. The retaining rings are fabricated from A240-316 stainless steel. The expansion joints are 28-1/8” O.D. x 24” long. Each unit was hydro pressure tested and inspected prior to shipping overseas. U.S. Bellows can provide rubber expansion joints up to 144” in diameter or higher for custom applications. Rubber pipe expansion joints are often used to compensate for minor misalignment and offset. The design is chemical and abrasion resistant while limiting sediment buildup. They have an integrally flanged design where no gaskets are required and are designed to absorb noise, vibration, and shock. This single, wide arch, spool-type rubber expansion joint is used to accommodate thermal growth while relieving piping stress during operation. This is just one of many types of rubber expansion joints we can provide to meet your specifications. If needed, using stress analysis, our experienced expansion joint engineers can assist in the design and development of expansion joints for your application.

Read MoreThick Wall Expansion Joints for Large Diameter Piping in a Heat Exchanger

U.S. Bellows, Inc. custom-designed thick wall flanged and flued head expansion joints for large diameter piping in a heat exchanger application. The expansion joints, including the liners, are fabricated from 316 stainless steel. The first unit is 60″ O.D. x 84″ O.D., the second unit is 36″ O.D. x 60″, and both units have a 1/4″ nominal thickness. They were designed for 4.4 psig at 210°F with a 122″ water column. A dye penetrant exam on the circumferential welds was conducted prior to shipping.

Read MoreU.S. Bellows Designed an Expansion Joint & Duct Work Assembly during a Plant Turnaround

US Bellows designed a universal expansion joint and duct work assembly for a 3rd pass outlet converter to economizer duct work application at a chemical plant in 8 weeks. Expansion joints are used in many economizer ductwork applications near boilers.

Plant turnarounds are a vital part of a plant’s maintenance program. They involve a scheduled stoppage of part or all of a plant’s operations. During this time, existing equipment such as expansion joints are removed and replaced with new or upgraded expansion joints. On-time delivery is critical to the plant turnaround schedule in order to limit the amount of time the plant is in shutdown.

The total assembly included a universal expansion joint, over 125 feet of custom-built 60” diameter duct work, including elbows, tees, saddles, nozzles, and spring supports. The expansion joints were designed for 0.3 degrees angular movement, 2.875″ lateral, and 3.25″ axial extension. The design conditions were 5 PSIG at 890°F. The liner, cover, and ducting are fabricated from 304 stainless steel, and the bellows are 321 SS. A dye-penetrant exam, soap & air test, and spot x-ray on all duct seam welds were performed before shipping. US Bellows has worked extensively on boiler units within the chemical industry and has provided products and designed supports for the unique requirements of economizers, including the use of stainless steel and super alloys to support applications such as this involving highly corrosive media.

Read More78” Dia. Universal Expansion Joint Custom-Designed for One of the Oldest Scientific Innovators in the Engineering Industry

US Bellows custom-designed universal expansion joints for one of the oldest scientific innovators in the engineering industry. Large diameter steam pipelines are a part of almost every plant and are associated with innovations in areas like nanotechnology, fuel cells, biomaterials from renewable resources, materials for personal protections (which have been especially important in the time of COVID), emerging video display technologies, and semiconductors. These plants manufacture polymers such as neoprene, nylon, chlorofluorocarbons, synthetic pigments. In this case, the universal expansion joint bellows and liner are fabricated from A240 Gr. 321, the pipe, tie rods, and flanges are fabricated from A240 Gr. 304 stainless steel. They are designed for low pressure (8 PSI) and range from 36” pipe x 60” long up to 78” pipe x 117” long. Per our QC requirements and/or client specifications, the expansion joints were dye-penetrate examined and soap, air bubble tested prior to shipment.

US Bellows Custom-Designed Tied Universal Expansion Joints for Service at a Chemical Plant

Universal expansion joints such as these are used in chemical plants that manufacture petrochemicals (such as ethylene and styrene monomer), polymers, and building products (PVC profiles for windows, doors, and decking). The units range in length from 26” to 48” and in diameter from 8” to 20”. The bellows were fabricated from 321 stainless steel, the weld ends, pipe spools, and flanges from 304 stainless steel, and the tie rods and hex nuts from carbon steel. They are designed for temperatures ranging from -150°F to 800°F, operating pressures ranging from 50 to 240 PSIG, and 0.25” to 2.25” of lateral deflection. The expansion joints were air, soap, and bubble tested, 100% dye-penetrant tested, and hydro-tested before shipment. The universal pipe expansion joint consists of two bellows separated by a pipe section or spool. The primary purpose of this arrangement is to have a unit that will accept large amounts of lateral deflection. The amount of lateral deflection they can accept is a function of the amount of angulation each bellows can absorb and the distance between the bellows. For a given bellows element, the amount of lateral deflection capability can be increased or decreased by simply changing the length of the center spool.

Read MoreGimbal Expansion Joints for Crude Oil Pipelines in Canada

US Bellows custom-designed and fabricated universal gimbal expansion joints for 24” diameter crude oil pipelines at a power plant in Canada. The bellows are fabricated from A240 316 stainless steel bellows, the flanges are A105N carbon steel, and the plates are A516 70 carbon steel. The expansion joints are designed for a 10 degrees angular rotation at 285 PSIG up to 100 degrees F. They are designed for an angular spring rate of 4900 in-lb/dec and vertical offset of 10-1/4”. The units measure 43” x 43” x 110” and 38” x 38” x 79”.

3D Modeling was done so that our engineers can check the “fit-up” to confirm the design, perform stress analysis, or other modeling benefits prior to fabrication. We performed hydro tests, completed NDE reports, and supplied material test reports per the client requirements.

Read MoreFabric Expansion Joints Custom Designed for an Exhaust Duct at a Gas Turbine in Saudi, Arabia

| Type: | Fabric Expansion Joint |

| Size: | 70″ W x 126″ L x 17.5″ Face-to-Face |

| Material: | PTFE Fabric Belt | Stainless Steel Framework |

| Design | Operating Temp: -20°F to 600°F | Operating Pressure +/- 100″ Water Column Movement +/- 1″ Axial Compression & Lateral Offset Combined |

| Testing: | Dye Penetrant Examined | Anchor Install Test& Q.C. Inspection |

US Bellows custom-designed a rectangular fabric expansion joint with rounded corners for an exhaust duct application at a gas turbine in Saudi, Arabia. The unit is 70″ W x 126″ L x 17.5″ face-to-face; the fabric belt is PTFE and the framework is stainless steel. The expansion joint is designed for an operating temperature range from -20°F to 600°F, an operating pressure of +/- 100″ water column, and a movement of +/- 1″ axial compression and lateral offset combined. A 100% dye-penetrate exam and anchor install test were performed before shipment.

Read MoreExpansion Joint Failures Due to Excessive Stress in the Piping System

US Bellows has spoken to many customers who complain about the premature failure of their expansion joints. In the vast majority of these cases, the issue is not a poorly made expansion joint but another issue in the piping system that places excess stress on the expansion joint.

Expansion joints are placed into piping systems for the following reasons:

- Thermal Growth (Piping Engineer) – The preferred method for absorbing thermal growth is an expansion loop, bend, or z. However, when there is not enough room in the system, an expansion joint can be used to absorb large amounts of thermal growth in a limited space.

- Alignment and Vibration (Rotating Equipment Engineer) – Some rotating equipment engineers will use expansion joints to solve alignment and vibration issues to keep stress off of sensitive rotating equipment.

Thermal growth will move to the path of least resistance. Expansion joints are designed to be the path of least resistance with a spring rate that is much lower than expansion loops and bends. This is also what makes expansion joints the weakest element in the piping system. The issue with expansion joints is that they can be sensitive to excess movement and are very sensitive to torsion. As a result, when the required movements in the piping system or overall process parameters change, it can adversely impact expansion joints. This can be caused by a lack of preventative maintenance, process changes to obtain greater output, poor installation, etc. The following are some of the scenarios PT&P has seen:

- Construction team using expansion joints for alignment – In order to save time, some construction teams will use an expansion joint to solve an alignment issue. This causes the following potential issues:

- Excess movement on expansion joint – If the expansion is compressed to solve an alignment issue, then it will be required to compress further beyond its initial design specification to absorb thermal growth. This can significantly reduce the life of the expansion joint.

- Excess stress in the piping system – If the expansion joint has limit rods, the use of the expansion joint for alignment may leave no room for the expansion joint to absorb thermal growth. In this case, the tremendous force associated with thermal growth will move to another part of the piping system.

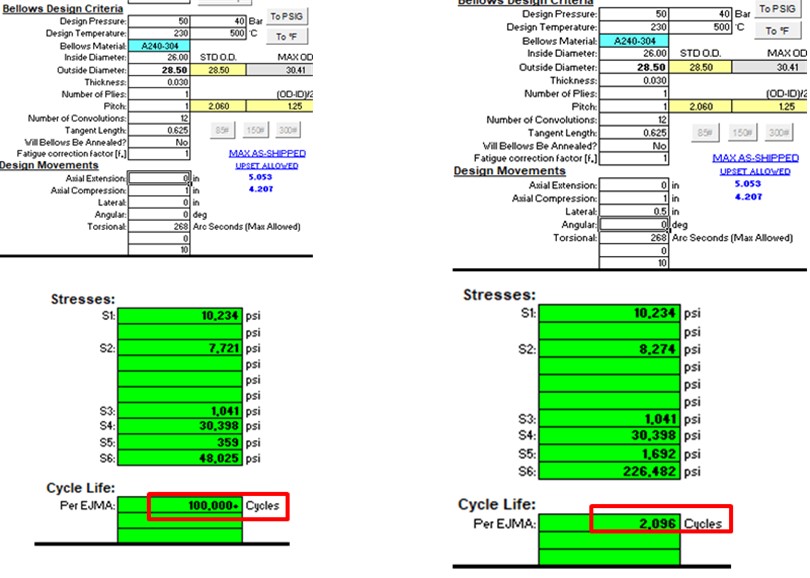

Spring Support Maintenance – When a spring support is not maintained, the stress and movements in the piping system can be altered significantly. For example, PT&P worked with a large chemical plant that was experiencing repeated expansion joint failures on a specific expansion joint. Upon review, the cause of the failure was that a constant spring supporting a long vertical run of piping was not being maintained. This was causing an issue for the expansion joint, which was on a horizontal run of piping that was feeding the vertical piping. The chart below shows an example of the impact of an expansion joint designed for 1” of axial movement when it is required to also support 0.5” of lateral movement. The requirement to support 0.5” of lateral movement reduces rates cycle life from 100,000+ cycles to 2096 cycles!

- Change in Process Parameters – The picture below is from a customer who experienced in-plane squirm because they raised the pressure in the piping system beyond the rated pressure of the expansion joint. Changes in pressure and temperature can move the system beyond the capability of the expansion joint. The picture below shows an in-plane squirm caused by an increase in process pressure in the piping system.

- Issues with Pipe Stress Analysis – One of the challenges with expansion joint design in pipe stress analysis is that pipe stress software does not provide detailed specifications for expansion joints the way it does for spring supports and other components. As a result, a design that places excess stress on an expansion joint can pass pipe stress analysis. For example, Caesar will not keep a designer from placing excess torsional force on an expansion joint (Pipe Stress Case Study).

US Bellows recommends a strong maintenance program to avoid these issues. This includes the following:

- Maintain Records of Expansion Joints – It is critical to know why the expansion joint was placed in the system and its intended movements.

- Regular Inspection of Expansion Joints – Expansion joints should be inspected for cracks, corrosion, and proper movement. Given the design parameters, the expansion joint should be checked for proper positioning in hot and cold positions to ensure it is being used as intended and there are no issues in the system that are going to impact the expansion joint.

- Ensure Installation Dimensions prior to Installation – To ensure that construction teams do not use expansion joints for alignment, measurements of the installation should be taken prior to installation to ensure that proper alignment has been done without the expansion joint.

Read More

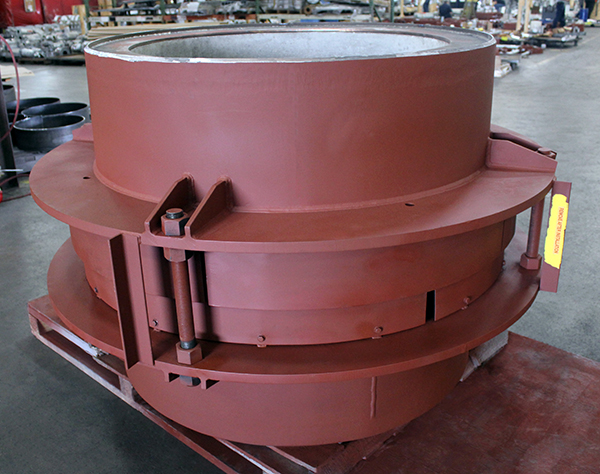

U.S. Bellows, Inc. Custom Designed a Refractory-Lined Expansion Joint for a Regenerator Application in Uruguay

| Type: | Refractory-Lined Expansion Joint |

| Size: | 43″ Tall x 39-1/2″ Dia. |

| Material: | Carbon Steel | INCOLOY® 825 | 3.75″ Thick Refractory |

| Design | Operating Temp: 653°F at 46 PSIG | 0.25″ Axial Compression |

| Testing: | Hydro-tested | Q.C. Inspection |

This refractory-lined expansion joint was custom designed for a regenerator application in Uruguay. The unit is 43″ tall, 39-1/2″ in diameter, fabricated from carbon steel and the bellows are INCOLOY® 825. It is lined with 3.75″ thick insulating and abrasion-resistant refractory. It is designed for an operating temperature of 653°F at 46 PSIG and 0.25” axial compression. The expansion joint was hydro-tested at 68 psig prior to shipment.

Read More