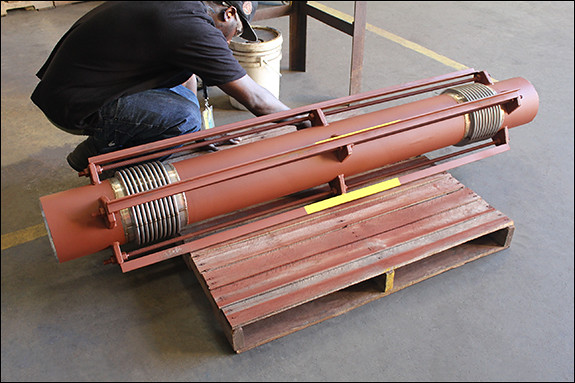

U.S. Bellows custom designed this universal expansion joint for a steam line extraction application at a power plant in Chile. The unit is 8″ in diameter with an overall length of 82″. The bellows were fabricated from 321 stainless steel with the weld ends and tie rods from carbon steel. The expansion joint is designed for an operating pressure of 145 psig at 678°F with 1.25″ of lateral deflection. All welds were 100% dye-penetrant examined and hydrotested prior to shipment.

Read MoreFeatured Product Archives

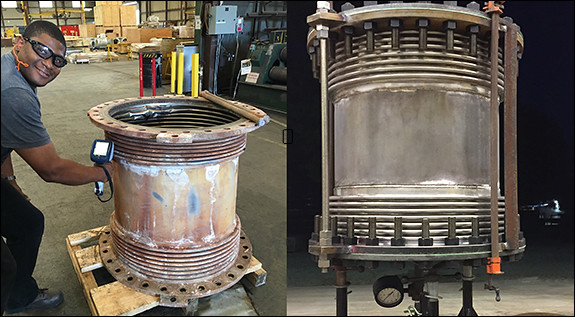

U.S. Bellows Emergency Response Team Refurbishes a Universal Expansion Joint on a Rush Basis for a Chemical Plant in Louisiana

Saturday morning of Memorial Day weekend, the US Bellows team received an emergency request from a large chemical plant who needed to refurbish an expansion joint by replacing both of the bellows. Within 30 minutes, the customer had a response and the project was under way.

US Bellows engineers consulted with the customer and requested the unit be shipped to the facility immediately. After receiving the expansion joint, the team performed a positive material identification (PMI) test. US Bellows assessed the expansion joint and determined the 316 stainless steel bellows could be refurbished. Once the results were concluded, engineering drawings and calculations were finalized.

US Bellows made certain that, despite the Holiday weekend, a skilled team of engineers, fitters, welders and quality control personnel were all involved to ensure the success of the project. The customer service and project success rates are unparalleled because US Bellows has the expertise and the tools we need to get it done right, the first time.

As with any last minute project, there were some unforeseen challenges. However, this didn’t stop the completion of the project, or even slow it down! The 30″ diameter universal expansion joint was refurbished and shipped back to the customer within 24 hours. The unit is back in service at the chemical plant with minimal down time due to the fast-acting U.S. Bellows team.

If you have an emergency request, including field service needs, please call us on our Emergency Hotline at (800) 787-5914 or via our online emergency request form

Read MorePTFE Coated Single Expansion Joints For A Power Plant in Mississippi

| Type: | Single Expansion Joint |

| Size: | 8″ Diameter and 7 1/8″ overall length |

| Material: | 304 Stainless Steel |

| Design | 160°F at 55 psig with 1/2″ of axil movement |

| Testing: | 100% Dye Penetrant | Hydro-tested |

U.S. Bellows custom designed these single expansion joint for a power plant in Mississippi. They are 8″ in diameter and 7 1/8″ overall length. The bellows were fabricated from 304 stainless steel and the flanges from carbon steel. The interior surface of the units were coated with PTFE. The expansion joints were designed for an operating temperature of 160°F at 55 psig with 1/2″ of axial movement. All unites were 100% dye-penetrant and hydro-tested prior to shipment.

Read MoreTied Universal Expansion Joint for a Sulphur Line at a Chemical Plant in Canada

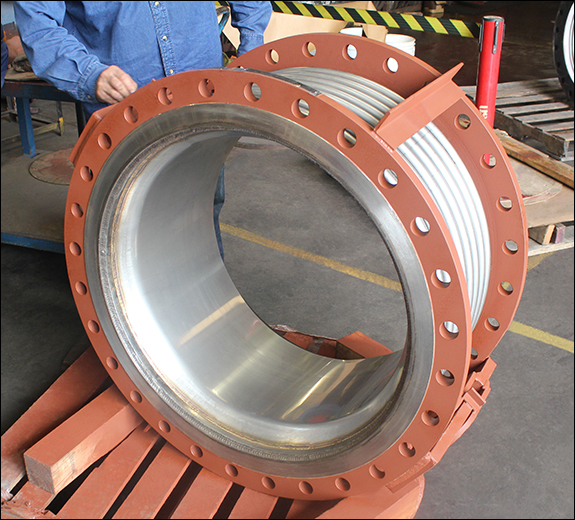

U.S. Bellows custom designed this tied universal expansion joint with floating flanges for a sulphur line application at a chemical facility in British Columbia, Canada. The expansion joint is 48″ in diameter and 72-1/2″ in length. The bellows is fabricated from 304 wetted stainless steel and the flanges and hardware from carbon steel. It is designed for an operating pressure of 10 pisg at 600°F with 1.8″ of axial compression. The unit was 100% dye- penetrant and pressure tested prior to shipment.

Read MoreExternally Pressurized Expansion Joints Designed for a Pipeline in Kentucky

US Bellows custom-designed these externally pressurized expansion joints for a pipeline in Kentucky. The bellows are fabricated from Inconel 625 LCF and all other components from carbon steel. The expansion joints are 4″ in diameter and 32″ OAL. They are designed for an operating pressure of 135 PSIG at 358°F with 3″ of compression. All expansion joints were hydro-tested prior to shipment. Externally pressurized expansion joints are suited for piping systems that require large amounts of axial compression or extension. In externally pressurized expansion joints, the bellows elements are arranged so that the media flow is on the external surface of the bellows. Externally pressurizing the bellows eliminates pressure instability as a limitation to the design and permits the absorption of large amounts of axial expansion.

Read MoreUniversal Gimbal Hinged Expansion Joint for a Methanol and Ammonia Plant in Texas

US Bellows designed this universal gimbal hinged expansion joint for a methanol and ammonia plant in Texas. This expansion joint is 48″ in diameter and 145″ OAL. The bellows were fabricated from Inconel 625 and the assembly is carbon steel. The unit is designed for an operating temperature of 752°F at 50 psig, the angular spring rate is 4,374 lb/in., with 3/4″ of axial movement within the gimbal bars. The unit was 100% x-ray, dye-penetrant, and hydro-tested prior to shipment.

Read More85″ Dia. Clamshell Spools Designed for an Exhaust Wall Protrusion Clamshell at a Gas Turbine Facility

These clamshell pipe spools were fabricated by U.S. Bellows for a section of the duct for a gas turbine installation. The units were constructed from ASTM A.240 type 321 stainless steel. The flanges had a 32 RMS machined faces for bolting up the flanges without gaskets. The spools were designed to be removed in four sections so that the spool could be removed and the turbine pulled back for maintenance. They are 85.5″ in diameter and 21.5″ in overall length. The units were designed for an operating temperature ranging from -40°F to 950°F.

Read MoreSeismic Universal Rectangular Expansion Joints for a clean room in California

U.S. Bellows custom built these seismic universal rectangular expansion joints for a clean room in California. The units were completely fabricated from 304 stainless steel and measure 68″ x 36″ x 51 1/2″. They are designed for an operating temperature of 68°F at +/-2″ water column and 1 1/2″ of movement in all directions. All units were 100% dye penetrant and air jet leak tested prior to shipment.

Read More30″ Dia. Hinged Expansion Joints Designed for a Pipeline in Mexico

Read MoreU.S. Bellows designed this hinged expansion joint for a pipeline in Mexico. It is 30″ in diameter and 18″ in length. The bellows are fabricated from 304 stainless steel, and the remainder of the assembly is carbon steel. The expansion joint is designed for an operating pressure of 25 psig at 986°F, with an angular movement of 4.5°. All units in this project were 100% dye-penetrant and hydro-tested prior to shipment.

Neoprene Expansion Joints Designed for a Generator Fan in a Gas Turbine Facility

US Bellows designed these EPDM neoprene fabric expansion joints for a generator fan application at a gas turbine facility. The expansion joints are 54″ in diameter and 15″ OAL. Each unit was fabricated has an EPDM fabric belt, stainless steel band clamps, and carbon steel angle flanged ends. The expansion joints are designed for -20°F/+200°F at +/- 100″ water column. A 100% dye penetrant examination on all carbon steel welds was conducted on all units prior to shipment.

Read More