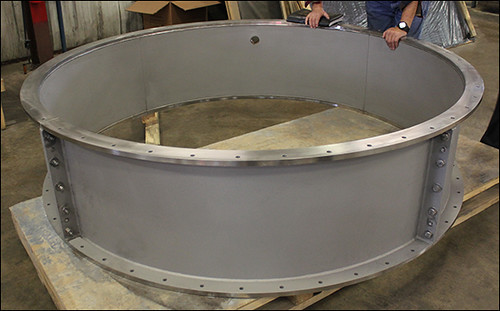

| Type: | Double Gimbal Expansion Joints |

| Size: | 30″ Diameter | 198″ Length |

| Material: | 2-Ply Bellows: Inconel 625 LCF | Pipes: 316 H SS | Covers & Liners: CS |

| Design: | 5° Angular Rotation | 1260°F | 180 psig |

| Testing: | 100% Dye-Penetrant | PMI Examined | Hydro-tested |

U.S. Bellows custom designed and fabricated double gimbal expansion joints for a chemical plant in Arkansas. The assemblies are designed with 2-ply bellows which were fabricated from Inconel 625 LCF. The pipes are 316 H stainless steel and the covers and liners are carbon steel. The units are 30″ in diameter and have an overall length of 198″. The expansion joints were designed for 5° angular rotation at 1260°F and 180 psig. Prior to shipment, the units were 100% dye penetrant tested, PMI examined, and hydro-tested.

Read More