US Bellows custom designed and manufactured a 5″ nominal diameter and 60″ long universal expansion joint for an oil piping system application in Nevada. This expansion joint consists of high-strength Inconel® 625LCF bellows and A105 flanges. The expansion joint is designed for 1400 PSIG and 120°F per B 31.3, and the latest revision of EJMA standards. It is also designed to allow 4 1/2″ of lateral movement during operation. A 100% dye-penetrant and hydro-test at 2100 PSIG was performed prior to shipment to ensure quality.

Read MoreTag: Tied Universal Expansion Joint

6″ Diameter Tied Universal Expansion Joints for a Steam Reformer

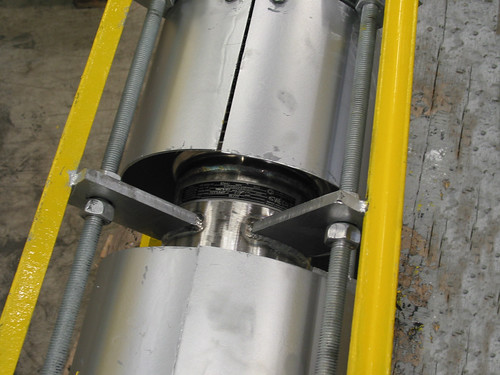

U.S. Bellows, Inc. recently designed and manufactured eight 6″ diameter tied universal expansion joints with 24” F-F. These expansion joints are made from two-Ply Inconel® 625 bellows, A312 TP 304 spool, and A105 flange. They are designed for FV/50 PSIG and 300°F with axial and lateral movements of +/- 0.25″ and 0.70″, respectively. The joints were 100% X-Rayed, 100% Dye-Penetrant, and hydro-yested at 75 PSIG. Flanges, tie rod, and spherical nuts are hot dip galvanized per customer specification.

Read MoreTied Universal Expansion Joints for Chemical Plant in Africa

These expansion joints were designed at 170 PSIG and 450 degrees F. to absorb lateral movements and tested per B31.3. They were made with Inconel® 625LCF bellows and A105 300 lb. RFSO flanges. The entire assembly was hydro-tested at 255 PSIG and held under pressure for four hours. In order to detect any leaks, each expansion joint and its welds were subjected to the dye penetrant-test and the X-ray test, each of which were 100%, prior to and following forming.

Read More14″ Diameter, Tied Universal Expansion Joints for a Power Plant in Illinois

These expansion joints were designed at 170 PSIG and 450 degrees F. to absorb lateral movements and tested per B31.3. They were made with Inconel® 625LCF bellows and A105 300 lb. RFSO flanges. The entire assembly was hydro-tested at 255 PSIG and held under pressure for four hours. In order to detect any leaks, each expansion joint and its welds were subjected to the dye penetrant-test and the X-ray test, each of which were 100%, prior to and following forming.

Read More14″ Diameter, Tied Universal Expansion Joints for a Power Plant in Illinois

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., designed and fabricated 14″ diameter, tied universal expansion joints for a steam application at a power plant in Illinois. The expansion joints were designed at 350 psig, 780° F and constructed from Inconel® 625 bellows, A105 300# RFSO flanges, A106 GR. B spool, and SA193 B7 tie rods. The expansion joints were hydro-tested at 525 PSIG

Read More