| Type: |

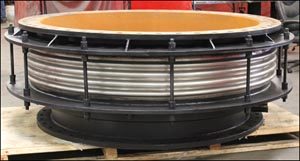

Single Expansion Joint |

| Size: |

59-7/15″ to 78-8/8″ and are 41-5/16″ long Diameter |

| Material: |

800H, A-240 type 304H stainless steel weld ends |

| Design |

lateral movement of 0.25″, axial movement of 2.64″ and 15 psig at 1231°F |

| Testing: |

100% X-Rayed | Dye-penetrant |

These single expansion joints are custom designed for an internal reactor in a propylene process unit. They are fabricated with Incoloy 800H bellows and A-240 type 304H stainless steel weld ends. The expansion joints range in diameter from 59-7/15″ to 78-8/8″ and are 41-5/16″ long. They were designed for a lateral movement of 0.25″, axial movement of 2.64″ and 15 psig at 1231°F. PMI, x-ray and dye penetration tests were performed prior to shipment.

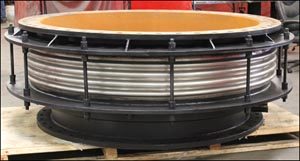

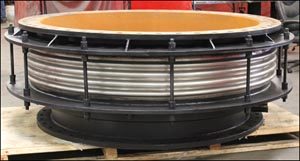

| Type: |

Single Expansion Joint |

| Size: |

59-7/15″ to 78-8/8″ and are 41-5/16″ long Diameter |

| Material: |

800H, A-240 type 304H stainless steel weld ends |

| Design |

lateral movement of 0.25″, axial movement of 2.64″ and 15 psig at 1231°F |

| Testing: |

100% X-Rayed | Dye-penetrant |

These single expansion joints are custom designed for an internal reactor in a propylene process unit. They are fabricated with Incoloy 800H bellows and A-240 type 304H stainless steel weld ends. The expansion joints range in diameter from 59-7/15″ to 78-8/8″ and are 41-5/16″ long. They were designed for a lateral movement of 0.25″, axial movement of 2.64″ and 15 psig at 1231°F. PMI, x-ray and dye penetration tests were performed prior to shipment.

Read More

|

This 42″ dia. x 13-3/4″ OAL single expansion joint was refurbished for a chemical plant. The bellows were replaced with 304 stainless steel and the flanges were sand blasted and painted. The expansion joint was designed for a spring rate of 4,253 lb./in., 5/8″ axial movement at 222°F and 50 psig. A dye penetrant examination and air soap and bubble test was conducted prior to shipping.

|

|

This 42″ dia. x 13-3/4″ OAL single expansion joint was refurbished for a chemical plant. The bellows were replaced with 304 stainless steel and the flanges were sand blasted and painted. The expansion joint was designed for a spring rate of 4,253 lb./in., 5/8″ axial movement at 222°F and 50 psig. A dye penetrant examination and air soap and bubble test was conducted prior to shipping.

|

Read More

| Type: |

Single Expansion Joint |

| Size: |

3″ to 56″Diameter |

| Material: |

321 stainless steel, 316L flanges, carbon steel covers |

| Design |

194°F at 22 PSIG |

| Testing: |

100% Dye-penetrant | Soap, and Air |

These single expansion joints are 20″ in overall length and range in diameter from 3″ to 56″. They are composed of 321 stainless steel bellows, 316L flanges, and angles, and include carbon steel covers. The expansion joints were designed for 194°F at 22 PSIG and were dye penetrant examined and soap and air tested prior to shipping to Peru.

| Type: |

Single Expansion Joint |

| Size: |

3″ to 56″Diameter |

| Material: |

321 stainless steel, 316L flanges, carbon steel covers |

| Design |

194°F at 22 PSIG |

| Testing: |

100% Dye-penetrant | Soap, and Air |

These single expansion joints are 20″ in overall length and range in diameter from 3″ to 56″. They are composed of 321 stainless steel bellows, 316L flanges, and angles, and include carbon steel covers. The expansion joints were designed for 194°F at 22 PSIG and were dye penetrant examined and soap and air tested prior to shipping to Peru.

Read More

| Type: |

Single Expansion Joint |

| Size: |

14″ dia. and 84″ Diameter |

| Material: |

304 stainless steel |

| Design |

spring rate of 2,530 lb/in., 1″ axial movement at 300°F and 37 psig |

| Testing: |

100% Dye-penetrant | Hydro-tested |

U.S. Bellows custom designed 14″ dia. and 84″ dia. single expansion joints for a pipeline in a utility plant in Colorado. The bellows are 304 stainless steel and carbon steel was used for the flanges and tie rods. The assemblies were designed for a spring rate of 2,530 lb/in., 1″ axial movement at 300°F and 37 psig. The assemblies were dye penetrant examined and air tested with a delivery of 12 weeks.

| Type: |

Single Expansion Joint |

| Size: |

14″ dia. and 84″ Diameter |

| Material: |

304 stainless steel |

| Design |

spring rate of 2,530 lb/in., 1″ axial movement at 300°F and 37 psig |

| Testing: |

100% Dye-penetrant | Hydro-tested |

U.S. Bellows custom designed 14″ dia. and 84″ dia. single expansion joints for a pipeline in a utility plant in Colorado. The bellows are 304 stainless steel and carbon steel was used for the flanges and tie rods. The assemblies were designed for a spring rate of 2,530 lb/in., 1″ axial movement at 300°F and 37 psig. The assemblies were dye penetrant examined and air tested with a delivery of 12 weeks.

Read More

| Type: |

Single Expansion Joint |

| Size: |

40″ and 42″ diameter |

| Material: |

304 Stainless Steel | Carbon Steel |

| Design |

lateral movement of 1/2″, and 15 PSIG at 250°F |

| Testing: |

100% Dye-penetrant | Hydro-tested |

These single tied expansion joints are 40″ and 42″ diameter and were designed for a solar electric generation facility. The bellows and flow liner are 304 stainless steel. The stub ends are fabricated from carbon steel. The expansion joints were designed for a lateral movement of 1/2″, and 15 PSIG at 250°F. They were 100% dye penetrant examined and hydro-tested prior to shipping to California.

| Type: |

Single Expansion Joint |

| Size: |

40″ and 42″ diameter |

| Material: |

304 Stainless Steel | Carbon Steel |

| Design |

lateral movement of 1/2″, and 15 PSIG at 250°F |

| Testing: |

100% Dye-penetrant | Hydro-tested |

These single tied expansion joints are 40″ and 42″ diameter and were designed for a solar electric generation facility. The bellows and flow liner are 304 stainless steel. The stub ends are fabricated from carbon steel. The expansion joints were designed for a lateral movement of 1/2″, and 15 PSIG at 250°F. They were 100% dye penetrant examined and hydro-tested prior to shipping to California.

Read More

| Type: |

Single Expansion Joint |

| Size: |

16″ diameter, 21-1/2″ OAL |

| Material: |

321 stainless steel |

| Design |

450°F at 8 psig |

| Testing: |

100% Dye-penetrant | Air and Soap-tested |

These single expansion joint are refurbished with 321 stainless steel bellows for an offshore deepwater drilling platform. They are 16″ diameter, 21-1/2″ OAL, and designed for 450°F at 8 psig. The expansion joints were dye penetrant examined, and an air and soap bubble test was performed prior to shipment.

| Type: |

Single Expansion Joint |

| Size: |

16″ diameter, 21-1/2″ OAL |

| Material: |

321 stainless steel |

| Design |

450°F at 8 psig |

| Testing: |

100% Dye-penetrant | Air and Soap-tested |

These single expansion joint are refurbished with 321 stainless steel bellows for an offshore deepwater drilling platform. They are 16″ diameter, 21-1/2″ OAL, and designed for 450°F at 8 psig. The expansion joints were dye penetrant examined, and an air and soap bubble test was performed prior to shipment.

Read More

| Type: |

Single Expansion Joint |

| Size: |

31″ |

| Material: |

321 stainless steel with Inconel 625 |

| Design: |

36″ long and is designed for 70 PSIG at 450 deg. F and axial travel of 4″ |

| Testing: |

100% Dye-penetrant | Hydro-tested |

Custom fabricated 31″ I.D. turbine expansion joint was designed and fabricated to be placed in service for a company in Texas. The expansion joint unit was reverse engineered, from the previous unit, with improvements to the current design. It is fabricated from 321 stainless steel with Inconel 625 bellows. The turbine expansion joint is 36″ long and is designed for 70 PSIG at 450 deg. F and axial travel of 4″. The expansion joint was 100% dye-penetrant examined and hydro-tested prior to being shipped to the customer.

| Type: |

Single Expansion Joint |

| Size: |

31″ |

| Material: |

321 stainless steel with Inconel 625 |

| Design: |

36″ long and is designed for 70 PSIG at 450 deg. F and axial travel of 4″ |

| Testing: |

100% Dye-penetrant | Hydro-tested |

Custom fabricated 31″ I.D. turbine expansion joint was designed and fabricated to be placed in service for a company in Texas. The expansion joint unit was reverse engineered, from the previous unit, with improvements to the current design. It is fabricated from 321 stainless steel with Inconel 625 bellows. The turbine expansion joint is 36″ long and is designed for 70 PSIG at 450 deg. F and axial travel of 4″. The expansion joint was 100% dye-penetrant examined and hydro-tested prior to being shipped to the customer.

Read More

This 48-3/4″ diameter single metallic expansion joint will be used in a heat exchanger. The bellows are 321 stainless steel and the pipe is 304 L stainless steel. This expansion joint is rated for 145 psi with 1″ compression and temperatures up to 600°F. The unit was 100% x-ray tested, hydro-tested and 100% dye penetrant tested

This 48-3/4″ diameter single metallic expansion joint will be used in a heat exchanger. The bellows are 321 stainless steel and the pipe is 304 L stainless steel. This expansion joint is rated for 145 psi with 1″ compression and temperatures up to 600°F. The unit was 100% x-ray tested, hydro-tested and 100% dye penetrant tested

Read More

This single tied expansion joint is custom designed with Inconel® 825 bellows with carbon steel flanges, liners and pipes. It is 76″ I.D., 90″ O.D. and is 31-1/2″ long. It was designed for 1,900°F at 100 psig with 1″ compression. A meshed expanded metal cover was installed to allow for hot air to escape. Tests performed included a 100% dye penetrant, x-ray, and ultrasonic on pressure bearing welds. Finished units were hydro-tested at 1.5 times the design pressure. The expansion joints were designed with an inner liner to accommodate for easier field installation of refractory lining.

This single tied expansion joint is custom designed with Inconel® 825 bellows with carbon steel flanges, liners and pipes. It is 76″ I.D., 90″ O.D. and is 31-1/2″ long. It was designed for 1,900°F at 100 psig with 1″ compression. A meshed expanded metal cover was installed to allow for hot air to escape. Tests performed included a 100% dye penetrant, x-ray, and ultrasonic on pressure bearing welds. Finished units were hydro-tested at 1.5 times the design pressure. The expansion joints were designed with an inner liner to accommodate for easier field installation of refractory lining.

Read More

A custom spring support was designed using a metal bellows instead of a spring coil. The bellows were fabricated from stainless steel because it will be used in a highly corrosive, off-shore environment. By utilizing the metallic bellows, it was much easier to customize for short-run production, produce variations of spring rate, and develop a high load-carrying capacity. An added benefit of using the bellows instead of a custom coil was that it reduced fabrication time by half. The rolled plate shown on the left is welded to the structural pipe on the platform and a riser clamp was attached on the right

A custom spring support was designed using a metal bellows instead of a spring coil. The bellows were fabricated from stainless steel because it will be used in a highly corrosive, off-shore environment. By utilizing the metallic bellows, it was much easier to customize for short-run production, produce variations of spring rate, and develop a high load-carrying capacity. An added benefit of using the bellows instead of a custom coil was that it reduced fabrication time by half. The rolled plate shown on the left is welded to the structural pipe on the platform and a riser clamp was attached on the right

Read More

The single flanged metallic expansion joint was manufactured from 304 stainless steel bellows with carbon steel flanges. It has a diameter of 20″ and an overall length of 15″. It will be used in an exhaust duct application in a power plant. A hydro-test was performed prior to shipping to Orlando, Florida.

The single flanged metallic expansion joint was manufactured from 304 stainless steel bellows with carbon steel flanges. It has a diameter of 20″ and an overall length of 15″. It will be used in an exhaust duct application in a power plant. A hydro-test was performed prior to shipping to Orlando, Florida.

Read More

U.S. Bellows, Inc. fabricated several expansion joints composed of 321 stainless steel and A588-A Corten angle flanges. The expansion joints measure 76″ in diameter and have an overall length of 27¾”. Each expansion joint is also lined with 4″ thick refractory lining.

The bellows long seams were 100% x-rayed and dye-penetrant tested. The bellows will be used in flue gas service associated with a clean fuels project at an oil refinery.

U.S. Bellows, Inc. fabricated several expansion joints composed of 321 stainless steel and A588-A Corten angle flanges. The expansion joints measure 76″ in diameter and have an overall length of 27¾”. Each expansion joint is also lined with 4″ thick refractory lining.

The bellows long seams were 100% x-rayed and dye-penetrant tested. The bellows will be used in flue gas service associated with a clean fuels project at an oil refinery.

Read More

U.S. Bellows, Inc. received this single expansion joint in the morning, refurbished it, and shipped it to the customer the very same day. The expansion joint bellows, liner, and cover were replaced. The carbon steel parts were sand blasted, cleaned and painted. The expansion joint was 4″ I.D. x 16 3/4″ face-to-face. The design conditions of the expansion joint were 345 PSI at 500°F. The expansion joint was 100% dye-penetrant examined and hydro-tested to 518 PSIG prior to being shipped back to a local area refinery.

U.S. Bellows, Inc. received this single expansion joint in the morning, refurbished it, and shipped it to the customer the very same day. The expansion joint bellows, liner, and cover were replaced. The carbon steel parts were sand blasted, cleaned and painted. The expansion joint was 4″ I.D. x 16 3/4″ face-to-face. The design conditions of the expansion joint were 345 PSI at 500°F. The expansion joint was 100% dye-penetrant examined and hydro-tested to 518 PSIG prior to being shipped back to a local area refinery.

Read More

U.S. Bellows, Inc. received this single expansion joint in the morning, refurbished it by adding new bellows and limit rods, and then shipped it the very same day. The existing expansion joint had 321 stainless steel bellows with 1,500 lb. flange on one side and 150 lb. flange on the other side. U.S. Bellows, Inc. manufactured new 321 stainless steel bellows and reused the existing flanges by sandblasting and then painting them for protection. Same day delivery enabled the customer to resume operations with minimum loss of time and production

U.S. Bellows, Inc. received this single expansion joint in the morning, refurbished it by adding new bellows and limit rods, and then shipped it the very same day. The existing expansion joint had 321 stainless steel bellows with 1,500 lb. flange on one side and 150 lb. flange on the other side. U.S. Bellows, Inc. manufactured new 321 stainless steel bellows and reused the existing flanges by sandblasting and then painting them for protection. Same day delivery enabled the customer to resume operations with minimum loss of time and production

Read More

U.S. Bellows, Inc. designed and fabricated single tied expansion joints for a pipeline in Alaska. The 12″ diameter expansion joints had an overall length of 12″ and the 24″ diameter expansion joint had an overall length of 14-1/2″.

The expansion joint assemblies are fabricated entirely from stainless steel. The design pressure of the expansion joints was 50 PSIG. They are designed with tie rods that do not permit axial movement, but allow for lateral movement up to 1/2″. The expansion joints will be used on a process line that contains exhaust gas and hydrocarbon vapor at a low concentration. It will connect an oil tank with a vapor control system. The expansion joints were 100% dye-penetrant tested and hydro-tested to ensure quality control.

U.S. Bellows, Inc. designed and fabricated single tied expansion joints for a pipeline in Alaska. The 12″ diameter expansion joints had an overall length of 12″ and the 24″ diameter expansion joint had an overall length of 14-1/2″.

The expansion joint assemblies are fabricated entirely from stainless steel. The design pressure of the expansion joints was 50 PSIG. They are designed with tie rods that do not permit axial movement, but allow for lateral movement up to 1/2″. The expansion joints will be used on a process line that contains exhaust gas and hydrocarbon vapor at a low concentration. It will connect an oil tank with a vapor control system. The expansion joints were 100% dye-penetrant tested and hydro-tested to ensure quality control.

Read More

|

|

These expansion joints measure 18″ in diameter x 11″ in overall length. Each expansion joint is fabricated with 300 lb. stainless steel raised face slip on flanges. The liner, cover, and tie-rods are fabricated from 316L stainless steel. The design pressure is 403 PSI, and the design temperature is 200°F. Dye-penetrant tests, hydro-tests at 604 PSIG, and 100% x-ray tests of the bellows’ longitudinal weld seams were performed to assure quality. |

|

These expansion joints measure 18″ in diameter x 11″ in overall length. Each expansion joint is fabricated with 300 lb. stainless steel raised face slip on flanges. The liner, cover, and tie-rods are fabricated from 316L stainless steel. The design pressure is 403 PSI, and the design temperature is 200°F. Dye-penetrant tests, hydro-tests at 604 PSIG, and 100% x-ray tests of the bellows’ longitudinal weld seams were performed to assure quality. |

Read More

|

|

U.S. Bellows, Inc. designed and fabricated 605 single expansion joints with a rectangular plate flange and a weld end. The expansion joints are 6″ in diameter and have an overall length of 15 3/8″. The design temperature was 525°F and the design pressure was 1 PSIG. Each expansion joint was 100% dye-penetrant tested and air & soap bubble tested. The expansion joints are to be installed in a heater for a delayed coker unit. |

|

|

|

U.S. Bellows, Inc. designed and fabricated 605 single expansion joints with a rectangular plate flange and a weld end. The expansion joints are 6″ in diameter and have an overall length of 15 3/8″. The design temperature was 525°F and the design pressure was 1 PSIG. Each expansion joint was 100% dye-penetrant tested and air & soap bubble tested. The expansion joints are to be installed in a heater for a delayed coker unit. |

|

Read More

|

|

|

|

| Details:

|

|

Design Conditions:

-

- Pressure: 243 PSIG

- Temperature: 108°F

- Axial Compression: 0.020″

- Lateral Movement: 0.200″

- Axial Spring Rate: 13,320 lb/in

- Lateral Spring Rate: 121,202 lb/in

|

|

|

|

|

| Details:

|

|

Design Conditions:

-

- Pressure: 243 PSIG

- Temperature: 108°F

- Axial Compression: 0.020″

- Lateral Movement: 0.200″

- Axial Spring Rate: 13,320 lb/in

- Lateral Spring Rate: 121,202 lb/in

|

Read More

|

|

|

These 6″ and 8″ in diameter flanged expansion joints were shipped to the customer a month ahead of schedule. The bellows are stock 321 stainless steel and the flanges are 150 carbon steel. They can take 1.22″ axial deflection, plus or minus 0.26″ lateral deflection and are designed to handle temperatures ranging from -24°F to 800°F. These expansion joints are rated up to 150 PSI and come equipped with an internal flow liner to allow for smooth fluid flow. They were 100% dye-penetrant tested and air & soap bubble tested to ensure quality. |

|

|

|

|

These 6″ and 8″ in diameter flanged expansion joints were shipped to the customer a month ahead of schedule. The bellows are stock 321 stainless steel and the flanges are 150 carbon steel. They can take 1.22″ axial deflection, plus or minus 0.26″ lateral deflection and are designed to handle temperatures ranging from -24°F to 800°F. These expansion joints are rated up to 150 PSI and come equipped with an internal flow liner to allow for smooth fluid flow. They were 100% dye-penetrant tested and air & soap bubble tested to ensure quality. |

|

Read More

|

These single expansion joints were fabricated from ASTM-A-240 Type 321 stainless steel bellows and liners. The shell material is ASTM-A-516 Grade 70. They are 32 diameters with an overall length of 26″. Each joint weighs 280 lbs. They were designed for 150 PSIG at 650F with a travel capacity of 0.33″ axial compression and 0.08″ lateral deflection. These expansion joints absorb differential expansion between the shell side and the tube side of a heat exchanger. |

They were hydrostatically tested to 208 PSIG to comply with the Japanese code, Ministry of Health, Labor and Welfares (MHLW), and the ASME Pressure Vessel Code Section VIII

|

These single expansion joints were fabricated from ASTM-A-240 Type 321 stainless steel bellows and liners. The shell material is ASTM-A-516 Grade 70. They are 32 diameters with an overall length of 26″. Each joint weighs 280 lbs. They were designed for 150 PSIG at 650F with a travel capacity of 0.33″ axial compression and 0.08″ lateral deflection. These expansion joints absorb differential expansion between the shell side and the tube side of a heat exchanger. |

They were hydrostatically tested to 208 PSIG to comply with the Japanese code, Ministry of Health, Labor and Welfares (MHLW), and the ASME Pressure Vessel Code Section VIII

Read More