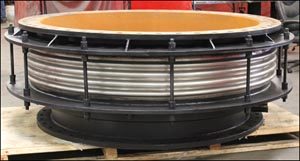

U.S. Bellows, Inc. designed and fabricated single tied expansion joints for a pipeline in Alaska. The 12″ diameter expansion joints had an overall length of 12″ and the 24″ diameter expansion joint had an overall length of 14-1/2″.

The expansion joint assemblies are fabricated entirely from stainless steel. The design pressure of the expansion joints was 50 PSIG. They are designed with tie rods that do not permit axial movement, but allow for lateral movement up to 1/2″. The expansion joints will be used on a process line that contains exhaust gas and hydrocarbon vapor at a low concentration. It will connect an oil tank with a vapor control system. The expansion joints were 100% dye-penetrant tested and hydro-tested to ensure quality control.

Read More