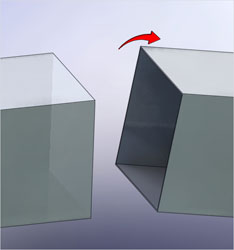

The twisting of one side of the duct about an axis perpendicular to the longitudinal axis.

The twisting of one side of the duct about an axis perpendicular to the longitudinal axis.

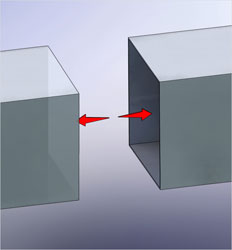

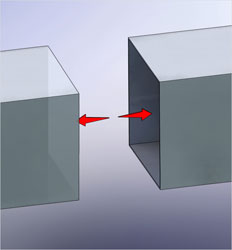

The increase in the breach opening along the axis of the duct. In certain configurations, the duct thermal expansion may result in extension at the expansion joint location.

It is the opening in the duct where the expansion joint is installed.

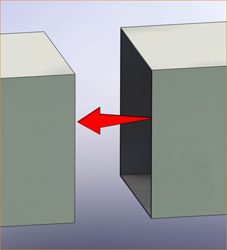

The reduction in the breach opening along the axis of the duct. This is usually a result of thermal expansion of the ducting.

It is a structural angle or channel that is welded to the end of the ducting facilitate bolting or welding the expansion joint into the system.

The rubber molded expansion joint would be used for water services or applications with low temperature.

The installed length is the overall face-to-face length of the expansion joint to be installed.

We can also do fabric expansion joints but that would be for a very low-pressure application.

The fabric is comprised of various layers:

The fabric joints do not have stiffness values as the metallic bellows do.

The maximum pressure for fabric expansion joints is 100 inches of water or 3 PSIG (pounds per square inch).

These expansion joints are not a good solution for high-temperature applications. The neoprene tends to burn at approximately 250 deg. F.

The number of layers or plies is dependent upon the design conditions and we usually limit non-metallic expansion joints to two or three layers.

We do manufacture fabric expansion joints with other types of materials if the customer specifies it. Please see some of the materials here:

Read MoreYes, the rubber expansion joints do have spring rates and that are required to be input into the stress model.

Yes, an externally pressurized expansion joint requires that the piping system be anchored.

We can allow for a total of 16″ of axial compression with a double x-flex expansion joint with an intermediate anchor base that will allow 8 inches of axial compression on either side of the anchor base.

You can use externally pressurized expansion joints in this application provided that the piping is anchored, supported, and guided correctly.

Understanding the various types of expansion joints is the first step toward selecting the right solution for your system. The primary categories are metallic, fabric, and rubber, each offering unique benefits and being suited for different operating conditions. These components ensure the lifespan of your infrastructure.

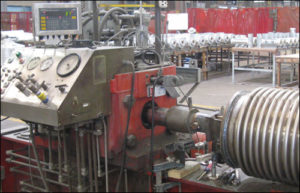

Metallic expansion joints, also known as bellows, are flexible elements used in piping systems to absorb movement caused by thermal expansion, vibration, and pressure fluctuations.

These are often made from thin-walled metal cylinders, such as stainless steel, that are formed into a series of convolutions or bellows. The shape of the bellows allows them to flex and compress, accommodating axial, lateral, and angular movement.

Fabric pipe expansion joints are often used in ducts that carry hot gases at low pressures. The primary design parameters are the temperatures and flow rates of the gases, as well as the amount and abrasiveness of solids suspended in the gases. Layers of different fabrics can be combined to accommodate the varying temperatures and pressures within the system. The fabric belt may need to be replaced periodically.

Rubber pipe expansion joints are often used to compensate for minor misalignment and offset. The design is chemical and abrasion resistant and accommodates higher pressures than the standard metal expansion joints and eliminates sediment buildup. They feature an integrally flanged design, eliminating the need for gaskets, and are designed to absorb noise, vibration, and shock. This single, wide arch, spool-type rubber expansion joint is provided with hot-dipped galvanized retaining rings.

Looking for the right expansion joint for your project? Download our catalog.

When cycle testing, the length of stroke is from neutral position to the compressed movement and back to neutral position of the expansion joint.