Ply refers to the number of sheet metal thicknesses used in the forming of the bellows. Therefore, a 2-ply bellows would be composed of two sheets of metal.

Heat exchanger shell bellows are used on fixed tube sheet heat exchangers. Bellows deflection is only axial and can be either extension or compression depending on the differential expansion of shell and tubes. In most cases the tubes are hotter than the shell, moreover tube material is sometimes high alloy, i.e. Stainless steel or nickel alloy, which expands about 50% more than carbon steel.

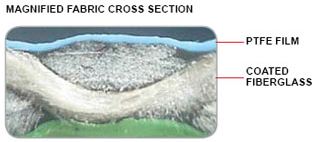

The expansion joint fabric is composed of two components: PTFE resins and fiberglass cloth.

Expansion Joints should be stored in a clean and dry environment. However, as a minimum, expansion joints must be stored so that water does not penetrate any closed container.

Styles Include: Style 200W, Style 100W, Style 300W, Style 600W, and Style 700W

The biggest limitation is the relatively low-temperature capability.

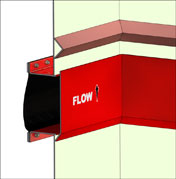

The belt radius is located at the corner of rectangular expansion joints. The radius corner helps prevent sharp creases that may shorten belt life.

Flexxcell FF1 is manufactured to a high weight without sacrificing the critical flexing properties required for a fabric expansion joint.

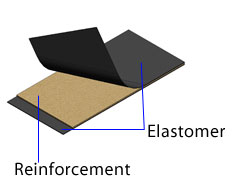

Yes, it can. The fabric belt must be able to withstand the thermal, pressure and chemical conditions. Modern fabrics accomplish this with a chemically inert barrier bonded to high strength substrate. For high-temperature applications, a layer of insulation is incorporated into the belt.

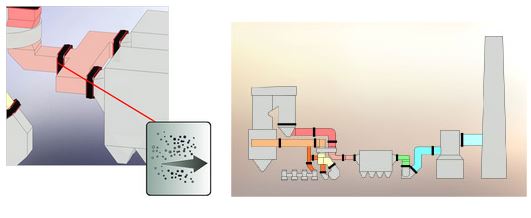

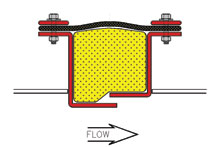

In certain conditions, a particulate deflector can be specified to reduce air-born particulate from falling down into the expansion joint cavity. This is most common on vertical ducting with the flow directions up and an upstream liner overlapping the downstream duct. The deflector presents an angled surface to the flow and eliminates a ledge for build-up.

Tools needed include: Suitable/safe scaffolding, Lifting equipment (forklift, crane, hoist), Drill, Come along, Rope, Pry Bar

The gasket is a non-porous deformable material that is installed between the belt attachment flange and the fabric belt. The gasket allows a gas-tight seal when the back-up bar clamping action is applied.

It includes integral telescoping liners to retain the accumulation barrier and protect the belt from abrasion.

It is defined as an assembly that utilizes a fabric belt element to allow for the movement of ductwork, as opposed to a metal expansion joint which allows for the movement by means of convoluted metal bellows.

Typical operating conditions are 600 degrees F to 750 degrees F, 5†to 80†WG pressure, clean air media, boiler growth contributes to large axial or lateral expansion joint movements depending on the orientation of the joints.

Bolt-in design for attachment to equipment or duct flanges. (If equipment or duct flanges are not present, weld in designs are recommended.)

In addition to fabric expansion joints, U.S. Bellows is a major designer and fabricator of ducting. Design Integration is the design, manufacture, and shipping of expansion joints integrated into the ducting as a complete unit directly from U.S. Bellows. This enables U.S. Bellows to offer optimum system design and the lowest installed cost.