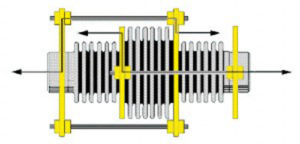

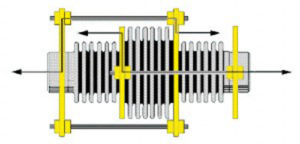

By using an in-line pressure balanced expansion joint.

By using an in-line pressure balanced expansion joint.

Regarding the operating temperature, we design metal pipe expansion joints up to 2000° F with refractory and 1000° F to 1500° F without refractory.

Toroidals can be used but not often. Most exchanges use normal thin-wall expansion joints or thick-wall expansion joints fabricated from flanged and flued heads.

The weight of the units is self-supporting but the additional weight of the piping, elbows etc. in the field will not be supported by the expansion joint.

Yes, this is one of the expansion joint functions

Read MoreNo, it is the total of the spring rates of all three bellows.

Read More

The number of expansion joints used in a pipe depends on the length of the pipe, the pressure, the temperature, and the size. Upon knowing these design conditions, we can inform you of the number of expansion joints the pipeline requires.

Read MoreAn expansion joint is used to absorb dimensional changes, such as those caused by thermal expansion or contraction of a pipeline, duct, or vessel.

The expansion joint used for fuel oil and fuel gas applications depends on the movement and design conditions of the particular application within the plant.

The spring rate is equal to the spring rate of both flow bellows plus the spring rate of the balancing bellows.

Expansion joints are needed to absorb thermal movement when piping flexibility will not solve the problem.

Expansion joints are required anywhere throughout the plant where thermal expansion must be absorbed. One example where expansion joints may be used in a power plant would be on piping running to power turbines or condensers.