US Bellows provided the total engineering, design, and fabrication package for this project including expansion joints, elbows, duct work, saddle supports, F-type variable spring supports, slide plates, and pipe anchors.

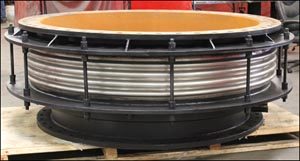

A total of twelve, 119″ dia. double-slotted hinged expansion joints, thirty-six, 72″ dia. elbows, and twelve, 119″ dia., 55″ long header ducts were fabricated for a power plant in Mississippi. The expansion joint assemblies were designed for .5° angular movement, 3/8″ lateral, 1-1/2″ axial compression. The design conditions were 5 psig at 300°F. The duct work was fabricated from A-36 carbon steel material and the bellows were fabricated from 304 stainless steel. A dye penetrant exam, soap and air test, and spot x-ray on all duct seam welds were performed prior to shipping.

Read More