Read More

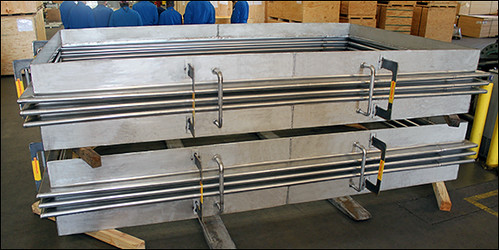

Type: Single Expansion Joints Size: 19 11/16″ Long | 12″ Nominal Pipe Size Material: 316 Stainless Steel | Carbon Steel Design: 220°F Operating Temp. @ 75 PSIG | 0.6″ Axial & Lateral Testing: 100% Dye-Penetrant US Bellows custom-designed these single expansion joints for an asphalt facility in Saudi Arabia. They are 19 11/16″ long and a nominal pipe size of 12″. The bellows and liners were fabricated from 316 stainless steel, with the flanges and tie rods from carbon steel. They are designed for an operating pressure of 75 PSIG at 220°F and 0.6″ axial compression and lateral deflection. The units were 100% dye-penetrant tested and hydro-tested prior to shipment.