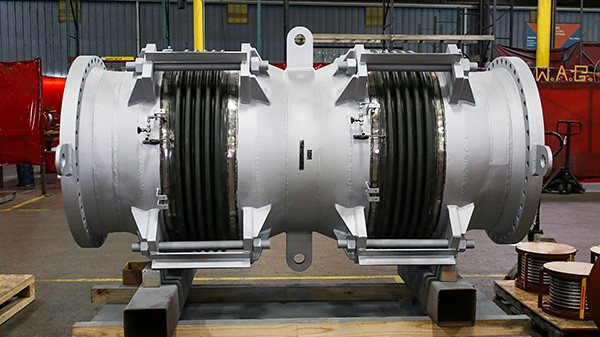

US Bellows custom-designed a pressure-balanced tee universal expansion joint for a boiler feed pump turbine exhaust within a power plant for a major electric utility provider in the Midwest with its founding roots in the 1880s, almost 140 years ago. Today they serve over 1.7M customers in the US, focusing on electricity generation, electric power transmission, and electricity distribution.

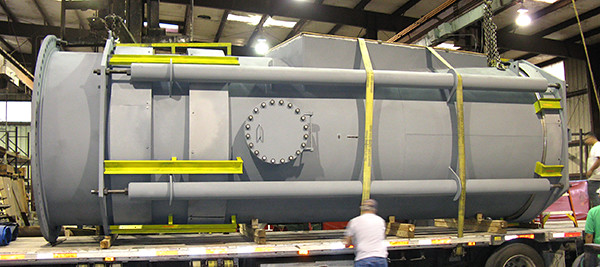

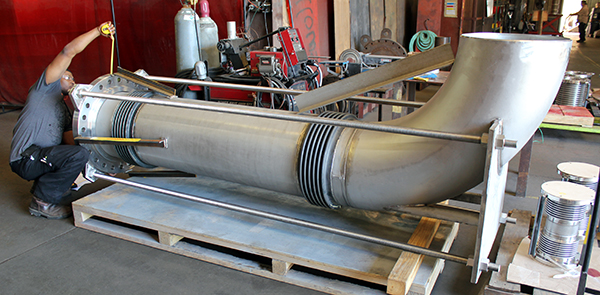

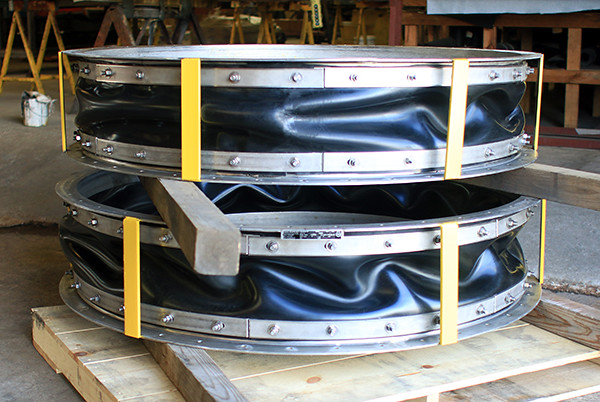

The expansion joint is 96″ in diameter and 288″ OAL and is designed for 2″ axial movement and 1/8″ lateral movement at both 15 PSIG and full vacuum (-14.7 PSIG) at 315 °F. The bellows, liner, and turning vanes are 304 stainless steel. The remainder of the assembly is fabricated from carbon steel. The expansion joint was dye penetrant examined, and a chemical cleaning of the interior surfaces was performed to remove any oil and grease. US Bellows also conducted a stress analysis and a pneumatic test at 23 PSIG.

Our US Bellows division is a member of the Expansion Joint Manufacturers Association (EJMA). EJMA is recognized as the world’s leading authority on the proper selection and application of metallic bellows-type expansion joints for safe and reliable piping and vessel installation. As a proud member, we design and manufacture our expansion joints to meet or exceed the guidelines and practices set forth by this association.

PT&P REF. ORIGINAL POST 03/02/2021

Read More