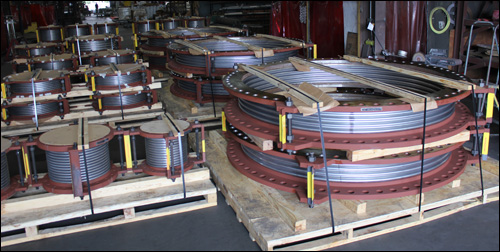

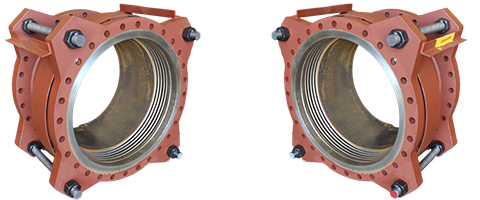

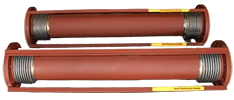

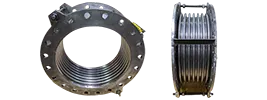

Single and Multi-ply Expansion Joint Bellows

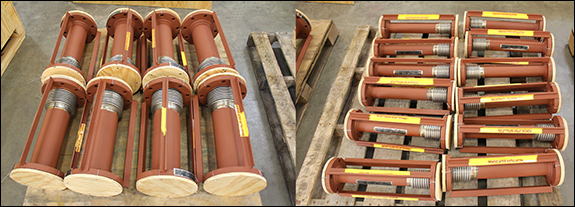

Single Expansion Joints by Nominal Diameter

3 1/2 Inch Single Expansion Joint

4 Inch Single Expansion Joint

5 Inch Single Expansion Joint

6 Inch Single Expansion Joint

8 Inch Single Expansion Joint

10 Inch Single Expansion Joint

12 Inch Single Expansion Joint

14 Inch Single Expansion Joint

16 Inch Single Expansion Joint

18 Inch Single Expansion Joint

20 Inch Single Expansion Joint

22 Inch Single Expansion Joint

24 Inch Single Expansion Joint

26 Inch Single Expansion Joint

28 Inch Single Expansion Joint

30 Inch Single Expansion Joint

32 Inch Single Expansion Joint

34 Inch Single Expansion Joint

36 Inch Single Expansion Joint

38 Inch Single Expansion Joint

40 Inch Single Expansion Joint

42 Inch Single Expansion Joint

44 Inch Single Expansion Joint

46 Inch Single Expansion Joint

48 Inch Single Expansion Joint

50, 52, 54 Inch Single Expansion Joint

60, 66, 72 Inch Single Expansion Joint

84, 96 Inch Single Expansion Joint

108, 120, 132 Inch Single Expansion Joint

144, 156 Inch Single Expansion Joint

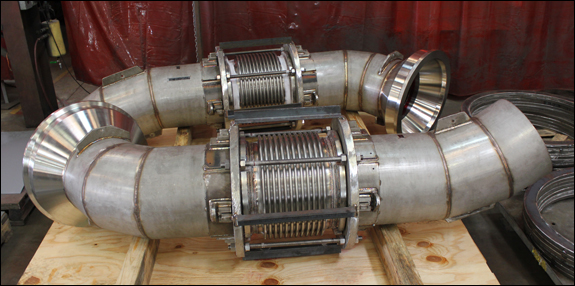

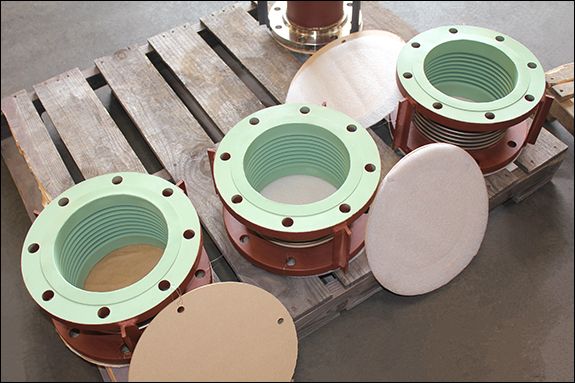

Features

- Absorbs small amounts of axial, lateral, and angular movements

- Deflect in any direction

- Most economical

- Must be guided

- Requires main and directional anchors

Technical Information

Installation & Maintenance (Metallic Expansion Joints)

Metal Bellows Material

Types of Metallic Bellows Deflections

Bellows Expansion Joint Loads

How to Look for Signs of Expansion Joint Failure

View more Technical Information

FAQs

How do you do a fatigue life cycle test for bellows?

How long is a burst test on an expansion joint?

Request a Quote