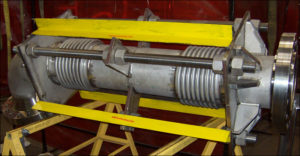

These tied universal expansion joints were custom designed by U.S. Bellows for a pipeline in Connecticut. All components of the expansion joints were fabricated from 316 stainless steel. The job was comprised of units that were 12″ or 16″ in diameter and 60″ in OAL. They are designed for an operating pressure of 10-125 psig at 450°F and a lateral movement of +/- 1″. All of the expansion joints were 100% dye-penetrant tested and hydro-tested at 150 and 175 psig prior to shipment.

Tag: Tied Universal Expansion Joints

Custom Designed Stainless Steel Tied Universal Expansion Joints

These tied universal expansion joints were custom designed by U.S. Bellows for a pipeline in Connecticut. All components of the expansion joints were fabricated from 316 stainless steel. The job was comprised of units that were 12″ or 16″ in diameter and 60″ in OAL. They are designed for an operating pressure of 10-125 psig at 450°F and a lateral movement of +/- 1″. All of the expansion joints were 100% dye-penetrant tested and hydro-tested at 150 and 175 psig prior to shipment.

Read More10″-16″ Tied Universal Expansion Joints for a Nitrogen Plant in Arizona

|

|||

|

|

||

12″ Expansion Joint:

|

10″ Expansion Joint:

|

||

|

|

||

16″ Expansion Joint:

|

10″ Expansion Joint:

|

||

Tied Universal Expansion Joint for Pipe Carrying Sulfur Dioxide

Read MoreThis tied universal expansion joint is designed to carry hot gas up to temperatures of 1022°F and pressure up to 5 PSIG. It has a 66″ inside diameter and is 72″ in overall length. The design movements are 4″ lateral and 4.5″ axial compression. The bellows’ material is Inconel® 825 with carbon steel weld ends. The bellows and pipe longitudinal weld seams were 100% x-rayed prior to a 5 PSIG air test and then dye-penetrant examined after testing.

48″ Diameter Tied Universal Expansion Joints for an Oil and Gas Company in France

U.S. Bellows, Inc. recently designed and manufactured five tied universal expansion joints ranging in size from 30 to 48 for an oil and gas company in France. These expansion joints weigh between 2400 lb. and 3200 lb. and are fabricated from 304-321 SS bellows. They are designed for pressures ranging from 55 to 650 PSIG and 148°F to 300°F operating temperatures. To ensure quality, the joints were 100% X-Rayed, 100% dye-penetrant, and hydro-tested at 83 to 975 PSIG.

Read More28″ and 32″ Tied Universal Expansion Joints for an Oil Refinery in China

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., fabricated 28-inch and 32-inch O.D Tied universal expansion joints for an oil refinery in China. The expansion joints were fabricated from 321 SS bellows, A105, 150#, RFSO. EJMA Standards and B31.3 code were used in the design and fabrication of these joints.

Read MoreElbow Tied Universal Expansion Joints for a Power Station in Florida

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., designed and manufactured 16-inch and 30-inch elbow tied universal expansion joints, for a power station in Florida. These expansion joints, which are used to transport hot steam, are designed at 150 psig and 350° F. The bellows material is fabricated from Inco 625 and elbows and spool from carbon steel.

Read More