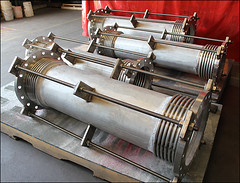

Expansion Joint Crated for Export

This tied universal expansion joint is fabricated from carbon steel pipe, tie rods and covers, and 304 stainless steel bellows and liners. The overall length of the expansion joint is 72″. The application of this expansion joint is to provide for large lateral movement in a propane dehydrogeneration plant. The expansion joint welds were 100% dye-penetrant examined and hydro-tested prior to shipment

Read More