–

U.S. Bellows designed and manufactured this 24″ diameter by 140-3/16″ OAL custom elbow pressure balanced expansion joint for a chemical plant in Missouri. The pipe and weld ends are fabricated from 347 stainless steel. The liner, tie rod lugs and end plates are fabricated from 304-H stainless steel. The bellows are Incoloy 800H. This expansion joint is designed for 2.6″ axial compression and 170 psig at 1200°F. The bellows longitudinal seams were 100% x-rayed, and the entire unit was dye penetrant examined and hydro-tested at 255 psig prior to shipment.

Tag: Pressure Balanced Expansion Joints

–

U.S. Bellows designed and manufactured this 24″ diameter by 140-3/16″ OAL custom elbow pressure balanced expansion joint for a chemical plant in Missouri. The pipe and weld ends are fabricated from 347 stainless steel. The liner, tie rod lugs and end plates are fabricated from 304-H stainless steel. The bellows are Incoloy 800H. This expansion joint is designed for 2.6″ axial compression and 170 psig at 1200°F. The bellows longitudinal seams were 100% x-rayed, and the entire unit was dye penetrant examined and hydro-tested at 255 psig prior to shipment.

This 60″ dia. x 20″ OAL elbow pressure balanced expansion joint was refurbished by U.S. Bellows in 3 weeks for a power generation plant in Wisconsin. The bellows are fabricated from Inconel 625 and the duct, elbow, cover and liner of carbon steel. The expansion joint was designed for 1″ axial movement at 715°F and 185 psig. The bellows longitudinal seams were 100% x-rayed prior to forming. After replacing the bellows, the expansion joint was dye penetrant tested and hydro tested at 185 psig.

60″ Dia. Elbow Pressure Balanced Expansion Joint Refurbished in 3 Weeks

This 60″ dia. x 20″ OAL elbow pressure balanced expansion joint was refurbished by U.S. Bellows in 3 weeks for a power generation plant in Wisconsin. The bellows are fabricated from Inconel 625 and the duct, elbow, cover and liner of carbon steel. The expansion joint was designed for 1″ axial movement at 715°F and 185 psig. The bellows longitudinal seams were 100% x-rayed prior to forming. After replacing the bellows, the expansion joint was dye penetrant tested and hydro tested at 185 psig.

Read MoreU.S. Bellows designed and manufactured a 64” diameter custom elbow pressure balanced expansion joint for an exhaust duct in a power plant in Alberta, Canada. It is 386” in overall length and is fabricated from carbon steel with 321 stainless steel bellows. This expansion joint is designed for 1-1/8” axial movement, ½” lateral movement at 482°F and 174 psig. Tests performed on the unit include 100% dye penetrant, x-ray, and ultrasonic on pressure bearing welds. The unit was also hydrotested at 291 psig prior to shipment.

64″ Dia. Elbow Pressure Balanced Expansion Joint Designed for an Exhaust Duct

U.S. Bellows designed and manufactured a 64” diameter custom elbow pressure balanced expansion joint for an exhaust duct in a power plant in Alberta, Canada. It is 386” in overall length and is fabricated from carbon steel with 321 stainless steel bellows. This expansion joint is designed for 1-1/8” axial movement, ½” lateral movement at 482°F and 174 psig. Tests performed on the unit include 100% dye penetrant, x-ray, and ultrasonic on pressure bearing welds. The unit was also hydrotested at 291 psig prior to shipment.

Read MoreU.S. Bellows refurbished a 54″ dia. custom crossover expansion joint for a power plant in Kansas. The flow end and balancing end bellows were replaced. The pressure balanced expansion joint was designed for 1″ axial movement at 700°F and 150 psig. The bellows longitudinal weld seams were 100% x-rayed and the assembly was hydro-tested at 180 psig prior to shipment. The refurbishment was completed in three weeks to meet the customer’s outage requirements.

54″ Dia. Refurbished Custom Crossover Expansion Joint

U.S. Bellows refurbished a 54″ dia. custom crossover expansion joint for a power plant in Kansas. The flow end and balancing end bellows were replaced. The pressure balanced expansion joint was designed for 1″ axial movement at 700°F and 150 psig. The bellows longitudinal weld seams were 100% x-rayed and the assembly was hydro-tested at 180 psig prior to shipment. The refurbishment was completed in three weeks to meet the customer’s outage requirements.

Read More

Pressure Balanced Elbow Expansion Joint

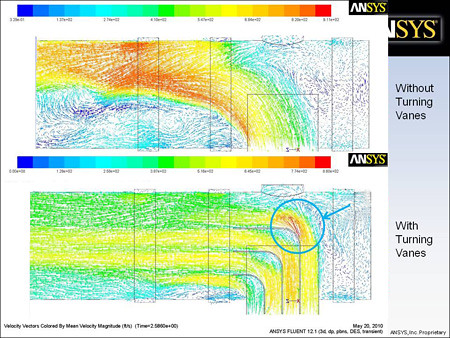

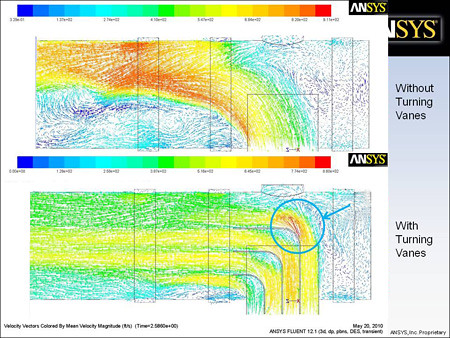

The existing pressure balanced elbow expansion joint with liners was re-designed with turning vanes to eliminate the vibration impact on the bellows. U.S. Bellows performed a computational fluid dynamics (CFD) analysis to determine the design of the turning vanes.

Computational Fluid Dynamics (CFD) Analysis

The turning vanes redirect the flow stream, which creates a smoother flow, thus eliminating the flow induced vibration. The bellows and liner were fabricated from 321 stainless steel and the rest is fabricated from carbon steel. An air and soap test was performed prior to shipping it to a power plant in Washington.

60″ Pressure Balanced Expansion Joint with Turning Vanes for a Power Plant in Washington

Pressure Balanced Elbow Expansion Joint

The existing pressure balanced elbow expansion joint with liners was re-designed with turning vanes to eliminate the vibration impact on the bellows. U.S. Bellows performed a computational fluid dynamics (CFD) analysis to determine the design of the turning vanes.

Computational Fluid Dynamics (CFD) Analysis

The turning vanes redirect the flow stream, which creates a smoother flow, thus eliminating the flow induced vibration. The bellows and liner were fabricated from 321 stainless steel and the rest is fabricated from carbon steel. An air and soap test was performed prior to shipping it to a power plant in Washington.

Read MoreU.S. Bellows, Inc. received this 26″ diameter pressure balanced elbow expansion joint for a complete refurbishment. The original condition of the expansion joint can be seen in the top image while the bottom image shows the expansion joint after being refurbished in just under 3 weeks. New SA-240 type 321 stainless steel bellows were used to replace the original bellows, and the tie rods and flow liners were also replaced. All carbon steel parts were painted with a universal primer. This expansion joint measures over 17 feet long center to center of elbows, and is currently being used in an effluent header at Cedar Bayou plant.

26″ Pressure Balanced Elbow Expansion Joint Refurbished for an Effluent Header

U.S. Bellows, Inc. received this 26″ diameter pressure balanced elbow expansion joint for a complete refurbishment. The original condition of the expansion joint can be seen in the top image while the bottom image shows the expansion joint after being refurbished in just under 3 weeks. New SA-240 type 321 stainless steel bellows were used to replace the original bellows, and the tie rods and flow liners were also replaced. All carbon steel parts were painted with a universal primer. This expansion joint measures over 17 feet long center to center of elbows, and is currently being used in an effluent header at Cedar Bayou plant.

Read MoreU.S Bellows, Inc, the expansion joint division of Piping Technology & Products, Inc., recently designed and fabricated three elbow pressure balanced expansion joints for a power station in Canada. These joints are designed at 150 PSIG and 450ºF to allow lateral and axial movements in a 42″ steam line. Expansion joints were designed and fabricated per EJMA and B31.1 code. The expansion joints were hydro-tested at 225 PSIG and 75ºF. In order to detect any leaks in the weld, prior to and following forming, bellows long seam welds and attachment welds were 100% dye-penetrant tested.

Elbow Pressure Balanced Expansion Joints for a Power Station in Canada

U.S Bellows, Inc, the expansion joint division of Piping Technology & Products, Inc., recently designed and fabricated three elbow pressure balanced expansion joints for a power station in Canada. These joints are designed at 150 PSIG and 450ºF to allow lateral and axial movements in a 42″ steam line. Expansion joints were designed and fabricated per EJMA and B31.1 code. The expansion joints were hydro-tested at 225 PSIG and 75ºF. In order to detect any leaks in the weld, prior to and following forming, bellows long seam welds and attachment welds were 100% dye-penetrant tested.

Read More