When calculating your pipe thickness, you want to take a few parameters into consideration:

Tag: pipe support

When calculating your pipe thickness, you want to take a few parameters into consideration:

At Piping Technology & Products, the term pre-insulated used in the context of pipe supports, refers to the feature of pipe shoes which allows a segment of the insulation to be incorporated into the support. This means that the insulation will be installed into position at the time of the support installation and remain in tact throughout the duration of the pipe support's lifespan.

Pre-Insulated Cryogenic Pipe Support

How do you pre-insulate pipe?

At Piping Technology & Products, the term pre-insulated used in the context of pipe supports, refers to the feature of pipe shoes which allows a segment of the insulation to be incorporated into the support. This means that the insulation will be installed into position at the time of the support installation and remain in tact throughout the duration of the pipe support's lifespan.

Pre-Insulated Cryogenic Pipe Support

At Piping Technology & Products, the density of the polyurethane that we offer 10 lb./cubic ft., 15 lb./cubic ft. and 20 lb./cubic ft. and 32 lb./cubic ft.

What is the density of polyurethane?

At Piping Technology & Products, the density of the polyurethane that we offer 10 lb./cubic ft., 15 lb./cubic ft. and 20 lb./cubic ft. and 32 lb./cubic ft.

Read MoreThe most common method for supporting vertical piping would be to first weld shear lugs into position, and then utilize a riser clamp which straddles the pipe. The load is then transferred by the riser clamp’s load bolts through hanger rod connections to our supporting structure.

22″ Diameter Riser Clamps

How is vertical piping suspended?

The most common method for supporting vertical piping would be to first weld shear lugs into position, and then utilize a riser clamp which straddles the pipe. The load is then transferred by the riser clamp’s load bolts through hanger rod connections to our supporting structure.

22″ Diameter Riser Clamps

The name of the temporary stand used to hold pipes in place are generally known as pipe stands.

Adjustable Pipe Stands

What is the name of the temporary stand used to hold pipes in place?

The name of the temporary stand used to hold pipes in place are generally known as pipe stands.

Adjustable Pipe Stands

Resting supports for piping could refer to a variety of supports that's main purpose is to support the pipe weight and is generally used where little or no pipe movement is anticipated.

Polyurethane Pipe Saddle Resting Support

Pipe trunnions could refer to a variety of supports that mainly function to support the pipe weight and generally used where little or no pipe movement is anticipated.

Insulated Trunnions

What is a pipe trunnion?

Pipe trunnions could refer to a variety of supports that mainly function to support the pipe weight and generally used where little or no pipe movement is anticipated.

Insulated Trunnions

Generally the centerline location of a pipe support is designated as the position on the supported pipe where the support midpoint intersects the pipe's central axis. The centerline of the pipe is shown on this Fig. 215 drawing below:

Pipe supports can be classifiedaccording to both their level of engagement (active or passive) and function(load-bearing, guiding, or anchoring).

We designate support configurations whose primary capabilities are always engaged as active, whereas passivesupport configurations simply follow the movement of the pipe during normal operation. However, disturbances such as severe weather, impact, abnormalvibration or seismic events, will activate these otherwise passive supports,which then function as active anchoring devices.

Pipe support functions include loadbearing, guiding, or anchoring. A load bearing support will uphold the weightof the pipe while allowing possible movement in all three dimensions. A guidewill uphold the weight of the pipe while restricting movement in up to twodimensions. An anchor will completely restrict pipe movement in all threedimensions while bearing the weight, side, and thrust loads.

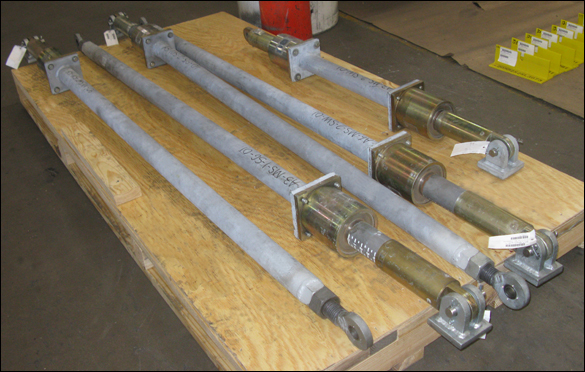

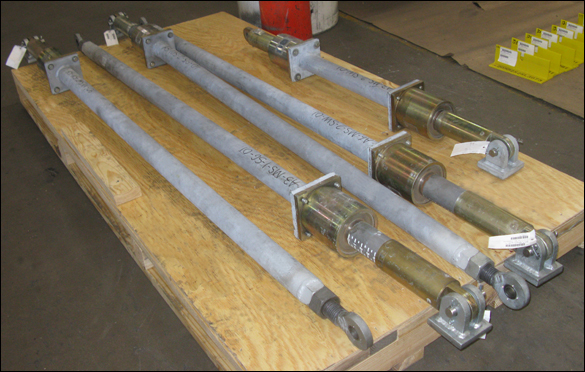

Hydraulic Snubber Assemblies – Passive Supports

What are the different types of pipe supports in refineries?

Pipe supports can be classifiedaccording to both their level of engagement (active or passive) and function(load-bearing, guiding, or anchoring).

We designate support configurations whose primary capabilities are always engaged as active, whereas passivesupport configurations simply follow the movement of the pipe during normal operation. However, disturbances such as severe weather, impact, abnormalvibration or seismic events, will activate these otherwise passive supports,which then function as active anchoring devices.

Pipe support functions include loadbearing, guiding, or anchoring. A load bearing support will uphold the weightof the pipe while allowing possible movement in all three dimensions. A guidewill uphold the weight of the pipe while restricting movement in up to twodimensions. An anchor will completely restrict pipe movement in all threedimensions while bearing the weight, side, and thrust loads.

Hydraulic Snubber Assemblies – Passive Supports