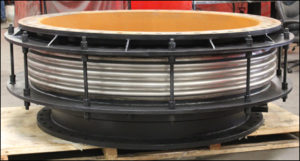

A pressure balanced expansion joint is a combination of several types of expansion joints. Its purpose is to retain and balance the pressure thrust so that main anchoring of the pipe or adjacent equipment is not required, and forces and movements on attachment flanges of delicate equipment, such as turbines, are kept to acceptably low levels.

Why are pressure balanced expansion joints used?

A piping system typically requires pressure-balanced expansion joints because axial deflections are also present. In order to accept these movements, a bellows is added beyond the elbow with the same cross-sectional area as the ones in the universal section.

This balancing bellows is connected by the tie rods to the pipe beyond the universal section; in this way, the pressure thrust is contained as tension in the tie rods. The section of the expansion joint between the tie rods, which includes the elbow, is now free to move axially, with the only resistance being a function of the spring rates of the bellows.

Because of their arrangement, however, the spring rate of the entire expansion joint is the sum of the spring rates of the balancing and the universal bellows. This is a constant volume system, in that when the universal end compresses, the balancing end extends the same amount. All of the lateral deflection is absorbed by the universal end, and there is no lateral deflection imposed on the balancing end. Therefore, the balancing bellows is almost always a single bellows type.

Looking for pressure balanced expansion joints? Visit our product page or speak with an engineer to know exactly what you need.

Did you know that US Bellows is a Piping Technology Company?

We are proud to be a one-stop solution from expansion joints to pipe supports and engineering services. We work hard to simplify your supply chain, and ensure system reliability with quality assurance.