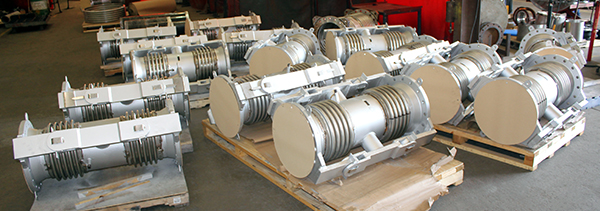

| Type: | Hinged Expansion Joints |

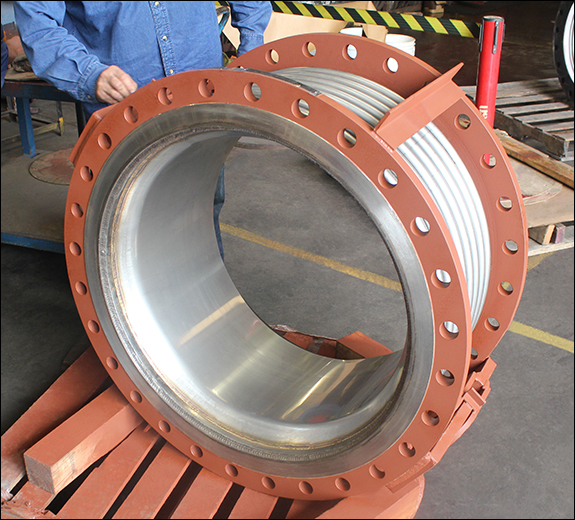

| Size: | 42″ Long | 16″ Nominal Pipe Size |

| Material: | 316L Stainless Steel | Carbon Steel |

| Design | 400°F at 150 psig | 4.25″ Lateral | 1° Angular |

| Testing: | 100% Dye Pen. | Bellows Longitudinal Seams 100% X-rayed | Hydro-Tested at 250 psig |

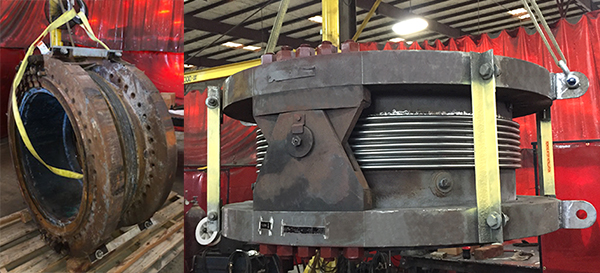

US Bellows custom-designed hinged universal expansion joint for a steam exhaust application at a chemical plant in Texas for one of the largest cracker installations in the USA to support the manufacture of mainly olefins and polypropylene. The units are 42″ long and have a nominal pipe size of 16″. The bellows are fabricated from 316L stainless steel. The flanges, pipe spool, and hardware are carbon steel. They are designed for an operating temperature of 400°F at 150 psig. They are capable of 4.25″ lateral deflection and 1° of angular movement. The expansion joints were 100% dye penetrant tested, the bellows longitudinal seams were 100% X-rayed, and a hydro-test at 250 psig was performed prior to shipment.

PT&P REF. ORIGINAL POST 02112020

Read More