Bellows squirm because they have surpassed the critical design pressure limit. This can occur in small diameter bellows with a large number of convolutions.

Bellows squirm because they have surpassed the critical design pressure limit. This can occur in small diameter bellows with a large number of convolutions.

By using an in-line pressure balanced expansion joint.

By using an in-line pressure balanced expansion joint.

Yes, the rubber expansion joints do have spring rates and that are required to be input into the stress model.

Yes, the rubber expansion joints do have spring rates and that are required to be input into the stress model.

The spring rate is equal to the spring rate of both flow bellows plus the spring rate of the balancing bellows.

The spring rate is equal to the spring rate of both flow bellows plus the spring rate of the balancing bellows.

The preferred method to design universal expansion joints would be to use a larger diameter bellows and use a reducer at the end of the expansion joint. This would ensure angular rotation and axial movement between the two bellows.

The preferred method to design universal expansion joints would be to use a larger diameter bellows and use a reducer at the end of the expansion joint. This would ensure angular rotation and axial movement between the two bellows. How do you design universal bellows with two different sizes?

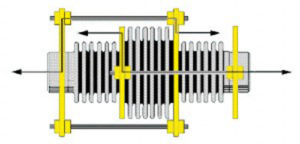

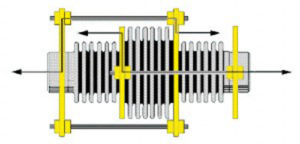

The expansion joint is designed to accommodate all the needed displacements. The tie-rods are part of the expansion joint and designed to absorb all the specified displacements.

The expansion joint is designed to accommodate all the needed displacements. The tie-rods are part of the expansion joint and designed to absorb all the specified displacements.

Universal expansion joints are usually used when there is large lateral motion.

Universal expansion joints are usually used when there is large lateral motion.