The bellows outside the elbow is called the balancing bellows. This bellows compensates for the movements. The elbow acts as an intermediate anchor and the tie rods absorb all of the pressured thrust forces.

Read MoreTag: faq

What is the difference between tie rod and limit rod?

The function of tie rods on an expansion joint is to continuously restrain the full pressure thrust during normal operation while permitting only lateral deflection. Limit rods are used to limit axial expansion or compression. Limit rods are designed to absorb the pressure thrust of the expansion joint in case of anchor failure.

Read MoreWhat is the bellows of an expansion joint?

A bellows is the flexible element of an expansion joint consisting of one or more convolutions and the end tangents, if any.

Read MoreWhat is lateral deflection?

Lateral deflection is movement perpendicular to the axial plane of the expansion joint. It is a shear motion on the bellows.

Read MoreWhat is free length in an expansion joint bellows?

Free length is the neutral length of the expansion joint bellows. This is the length of the bellows that has neither been compressed nor extended.

Read MoreWhat is flow rate?

The flow rate is the amount of liquid passing through a particular area over a period of time. It is generally measured in gallons per a minute or cubic feet per meter.

Read MoreWhat is expansion joint O.A.L.?

O.A.L refers to the overall length of the expansion joint.

Read MoreWhat is bellows I.D.?

Bellows I.D. refers to the inside diameter of the bellows.

Read MoreWhat is a swing expansion joint?

A swing expansion joint is another term used for a hinge type expansion joint.

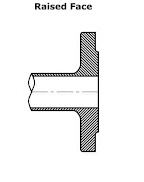

Read MoreWhat is an RFSO flange?

RFSO Flanges, also known as “Raised Face Slip-On Flanges,” is a type of pipe flange on the edges of expansion joints in which the bolting circle face is slightly elevated. Moreover, as a slip-on flange, it can slide over the pipe to provide a better seal and protect against leakage. This is best used in low-to-moderate pressure applications, and is preferred in situations where welding access is easier and lower-cost fabrication is desired.

Read MoreWhat is angular deflection?

When an expansion joint experiences bending about its center, which is on the centerline and halfway between the ends of the bellows, this deflection is referred to as angular. It can occur in any plane that passes through the centerline, but the plane should be clearly indicated if the expansion joint is more complicated than the simplest type, i.e., only a bellows with flanges or pipe ends. As in lateral movements, piping analyses may reveal angular deflections occurring in more than one plane. With angular deflection the basis for the proper selection is the maximum of the various deflections, and not the vector sum as in the lateral case. Multiple angular deflections in multiple planes produce a single angular deflection in a single resultant plane. As in lateral deflection, this plane must be understood if structural components are to be used.

Read MoreWhat is an FCC unit?

An FCC unit is a fluid catalytic cracking unit, which is a type of process that is used in refining crude oil into gasoline. The expansion joints used for the service are called stand pipe expansion joints.

Read MoreWhat is an expansion joint?

An expansion joint is an assembly used in a pipe line to allow it to expand and contract as climate conditions move from hot to cold and helps to ensure that the system remains functional.

Read MoreWhat is 300 psig?

This is an expansion joint specification meaning the expansion joint is rated for 300 pounds per square inch of pressure.

Read MoreWhat happens if a fabric expansion joint is exposed to sudden pressure fluctuations, such being located near ID fans and dampers?

This may result in the belt fluttering. The fabric will fatigue over time resulting in tears. Using stiffer fabric material, installing a liner and increasing the standoff are steps to take avoid flutter.

Read MoreWhat does cold preset 2.5″ mean?

Cold preset of 2.5″ is performed in the shop on one side of the center line so that in operation the expansion joint will return to the neutral position.

Read MoreWhat causes expansion?

Expansion is caused by heat being applied to a piping system.

Read MoreWhat are wipers on slip type pipe expansion joints?

On slip type pipe expansion joints special features such as wipers can be included to prevent clogging of the space provided for slip movement.

Read MoreWhat are the travel limits for the tie rods?

The limiting factors correspond to the limiting factors of the bellows design in accordance with the specifications of each expansion joint.

Read MoreWhat are the three basic movements within a joint?

The three basic movements within an expansion joint are axial, lateral, or angular rotation. All three of these movements do not generally occur at the same time.

Read More- « Previous Page

- 1

- 2

- 3

- 4

- …

- 19

- Next Page »