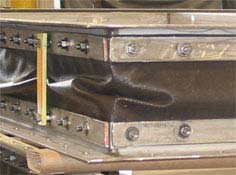

The rectangular fabric expansion joints consisted of two carbon and stainless steel frames separated by a high-temperature Silica fabric. The frames measured 13” × 37” × 6”, 14½” × 20½” × 6” and 17¼” × 17¼” × 4” and weighed 90, 115, and 170 lb. Each expansion joint was designed for a 15” Water Column (W.C.) with a temperature of 750°F and allowed for movement ranging from ±½” to ±1” in both the axial and lateral directions.

Tag: Fabric Expansion Joints

U.S. Bellows, Inc. Designed and Fabricated Fabric Expansion Joints for a Power System Company in Texas

|

|

Expansion Joint Ready for Inspection |

Read More

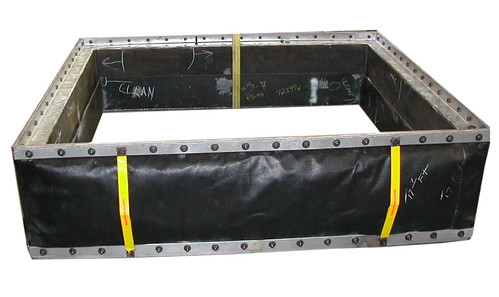

US Bellows recently custom-designed and fabricated 17 rectangular fabric expansion joints for a power system company in Texas. The expansion joints measure 54″ x 136″ and weigh 135 lb. each. They are designed for operation up to 5 PSIG and temperatures up to 400°F. The expansion joints are made of fiberglass fabric and have stainless steel frames

Fabric Expansion Joints for Power System Company in Texas

US Bellows recently custom-designed and fabricated five fabric expansion joints for a power system company in Texas. The expansion joints range in size from 30″ to 62″ in diameter, and the rectangular expansion joints measure 81″ x 18″ and 136″ x 54″. They are designed to operate from 0.8 to 5 PSIG and in temperatures ranging from -40˚F to 400˚F. The products were fabricated using Neoprene and fiberglass fabric with carbon and stainless steel frames. A special paint system was applied per the customer’s request. Additionally, the products were manufactured according to the customer’s specific quality specifications.

78″ x 39″ Rectangular Fabric Expansion Joint for a Power Company in Texas

U.S. Bellows, Inc. custom designed and fabricated a 315 lb. 78 x 39 multi-layer fabric expansion joint for a power company in Texas. This fabric expansion joint will be mounted inside a turbine enclosure and allows for a 15,000 cfm air flow through the enclosure. It is designed for 27 1/2 W.C. and 930°F with 0.27 axial and ± 0.12 lateral movements. The expansion joint is equipped with a stainless steel frame and a 6 thick insulated pillow which is enclosed in a stainless steel woven wire mesh.

5′ x 12′ Fabric Expansion Joint for a Power Plant in Oklahoma

U.S. Bellows, Inc. recently designed and manufactured a 5′ – 0″ x 12′ – 0″ fabric expansion joint for a hot air ducting system in a power plant in Tulsa, OK. It is designed at 15″ W.C. and 600 °F for 3/4″ axial movement and 1/2″ lateral movement. The fabric belts are composed of three layers with the outer layer serving as a waterproof barrier.

Read MoreRectangular Fabric Expansion Joint for Coal Fired Power Plant in Puerto Rico

U.S. Bellows, Inc. designed and manufactured a 21’ x 14′ fabric expansion joint for a power plant in Puerto Rico. This expansion joint was designed at 1 PSIG and 1200 °F for an air duct at the power plant. The frame is all A-240 and 304 stainless steel construction. This expansion joint is equipped with 6” thick insulation pillows. Telescoping liners hold the insulation pillows between the liner and the fabric belt to reduce heat transfer and prevent ash accumulation.

87 Fabric Expansion Joints for a Furnace Application at a Chemical Plant in Texas

U.S. Bellows, Inc. manufactured 87, rectangular fabric expansion joints for a furnace application at a chemical plant in Texas. The joints were designed at 11″ W.C. and 750 degrees F for ½ ” axial and lateral movements. The fabric belts on these joints are composed of three layers. They were equipped with a telescoping liner and 2″ thick insulation pillows to reduce the heat transfer.

Fabric Expansion Joints Up to 32′ x 12′ for a Power Station in New York

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., specially designed and manufactured fabric expansion joints reaching sizes up to 32′ x 12′ for a power station in New York. The largest of the expansion joints that are to support the air ducts of the power station, was designed at 32′ x 12′, while the others measured at 10′ x 12′. The expansion joints were fabricated with high-temperature fabric belts and 4″ thick insulation pillows. The designing conditions were at 30″ WC and 950°F.

12′ x 30′ x 12″ Face to Face, High Temperature, Fabric Expansion Joint for a Power Plant in New York

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., specially designed and fabricated a 12′ x 30′ x 12″ face to face, high temperature, fabric expansion joint. The expansion joint was fabricated with a 3-layered fabric belt, A516 Gr. 70 telescoping liners / frame, and insulation pillows. It was designed at 650°F and 30″ WC for 1/2″ compression and 1/4″ lateral. This expansion joint will be installed in an exhaust system at a power plant in New York. EJMA standards, Fluid Sealing Association standards, and B31.3 code were used in the design and fabrication of these joints.

48″ Triple Layered Fabric Expansion Joints

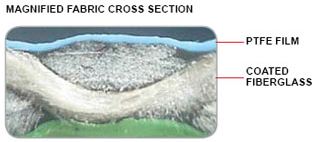

U.S. Bellows, Inc., the expansion joint division of Piping Technology & Products, Inc., designed and fabricated two 48-inch, triple-layered fabric expansion joints for a power plant in Columbia to be used in its exhaust system. The expansion joints were fabricated with three layers: outer, center and inner. The outer layers consisted of PTFE, 25% glass filled, coated fiberglass, center layers of ceramic fiberglass and the inner layers of aluminum-coated fiberglass. These expansion joints were designed at a pressure of 27” of WC and a temperature of 700°F.

What are FLEXXCEL Flouroplastic materials composed of?

The expansion joint fabric is composed of two components: PTFE resins and fiberglass cloth.

Where can I store a fabric expansion joint?

Expansion Joints should be stored in a clean and dry environment. However, as a minimum, expansion joints must be stored so that water does not penetrate any closed container.

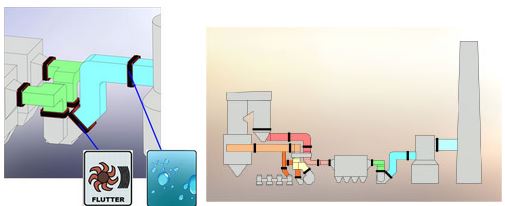

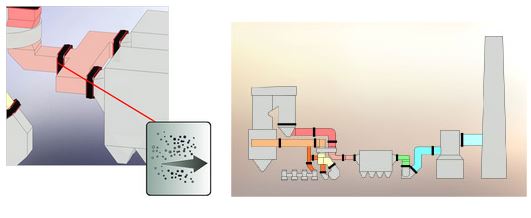

What are styles of dirty flue gas expansion joint applications?

Styles Include: Style 200W, Style 100W, Style 300W, Style 600W, and Style 700W

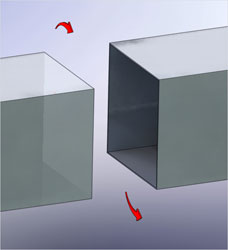

On a fabric expansion joint where is the radius corner located?

The belt radius is located at the corner of rectangular expansion joints. The radius corner helps prevent sharp creases that may shorten belt life.