U.S. Bellows, Inc. designed and fabricated 44″ fabric expansion joints for a petrochemical plant in Malaysia. The expansion joints measure 44″ ID x 40″ face to face and are fabricated from stainless steel pipe and flanges and a three layer fabric belt protected by an insulation pillow. The design conditions were 3 PSIG at 845°F. The expansion joints are designed for a lateral movement of 1/2″ and an angular rotation of 1.5°. Stainless steel covers were included to protect the fabric expansion element from possible outside damage.

Tag: fabric expansion joint

U.S. Bellows, Inc. Designed and Fabricated Expansion Joints that Required Helium Leak Testing

|

||

|

This order required custom engineering to design and manufacture these expansion joints due to their critical service condition requirements. PT&P manufactured and tested these expansion joints to the customer specifications, EJMA Standards, and US Bellows Quality Standards.

Design Condition:

| 176 PSIG at 500°F | |

| 0.5 Axial Extension and 1.5 Axial Compression | |

| 18″ 304 Stainless Steel Expansion Joints with Special Designed and Machined Flange Faces with a Specially Designed Gasket Groove | |

| Special Customer Welding Requirements to A.W.S. Standards | |

| Critical Spring Rate Requirements | |

| Stringent Testing Requirements | |

| The Bellows Longitudinal Seams were 100% X-Rayed and Dye-Penetrant Examined. | |

| Each Expansion Joint was Helium Leak Tested to a Leak Rate of 1 x 10 ֿ 7 |

60″ Ductwork with Spring Supports, Snubbers, a Support Cradle and a Fabric Expansion Joint

U.S. Bellows, Inc. and PT&P combined to furnish a fabric expansion joint, duct work, a spring support cradle and snubbers. US Bellows furnished a fabric expansion joint with acid resisting fabric and also a duct work measuring 34″ long and 60″ in diameter which was fabricated from ASTM A 516GR 70 carbon steel. PT&P furnished spring supports, carbon steel cradle supports, and snubbers. The expansion joint was completed within 6 weeks in time for a plant shutdown. A computerized pipe stress analysis, utilizing the Caesar II stress program, was performed to obtain the forces and moments imposed on the equipment nozzles and weights to be carried by the spring supports.

Read MoreReplacement Fabric Expansion Joint for Methanol Plant in Russia

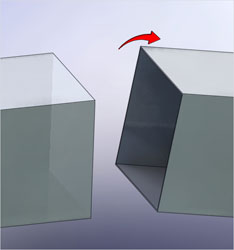

The photograph above shows rectangular expansion joints being prepared for shipment to Russia. These were fabricated to replace units in a methanol plant duct system. The fabric belt is constructed of layers of material selected to handle the hot gases at low pressures. The frames can be fabricated from a variety of metals in a variety of shapes depending on the particular application.

Rectangular Fabric Expansion Joint

The photograph above shows a rectangular fabric expansion joint in the final stages of assembly. The fabric “belt” is being attached to the metal frames. These expansion joints are inserted in metal ducts that carry hot gases at low pressures. Layers of different materials are selected to make a “belt” which will function at the high temperatures required.

Fabric Expansion Joint for Duct System

The photograph above shows a fabric expansion joint designed and built for installation in a duct system by Piping Technology & Products, Inc. These joints can be fabricated from a variety of metals, in a variety of shapes, depending on the particular application. They are used where ducts carry hot gases at low pressures. The fabric “belt” is a combination of layers of different materials selected to withstand the high temperatures.

High-Temp Fabric Expansion Joints

Shown above is a large, round fabric expansion joint designed and fabricated by U.S. Bellows. The fabric “belt” is attached between two short sections of pipe. These expansion joints are inserted in metal pipes that carry hot gases at low pressures. Layers of different materials are selected to make a belt that will function at the high temperatures required. U.S. Bellows designs and fabricates these items to meet customer requirements.

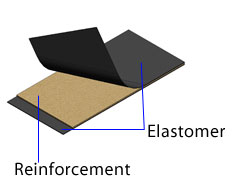

What is a drawback of FLEXXCEL elastomeric belt materials?

The biggest limitation is the relatively low-temperature capability.

How is the Flexxcell FF1 manufactured?

Flexxcell FF1 is manufactured to a high weight without sacrificing the critical flexing properties required for a fabric expansion joint.

For fabric expansion joints can the fabric belt withstand thermal, pressure and chemical conditions?

Yes, it can. The fabric belt must be able to withstand the thermal, pressure and chemical conditions. Modern fabrics accomplish this with a chemically inert barrier bonded to high strength substrate. For high-temperature applications, a layer of insulation is incorporated into the belt.

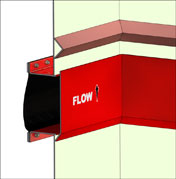

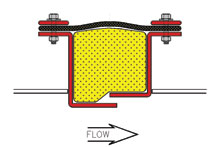

What is the function of the particulate deflector on a fabric expansion joint?

In certain conditions, a particulate deflector can be specified to reduce air-born particulate from falling down into the expansion joint cavity. This is most common on vertical ducting with the flow directions up and an upstream liner overlapping the downstream duct. The deflector presents an angled surface to the flow and eliminates a ledge for build-up.

What tools are needed to install a fabric expansion joint assembly?

Tools needed include: Suitable/safe scaffolding, Lifting equipment (forklift, crane, hoist), Drill, Come along, Rope, Pry Bar

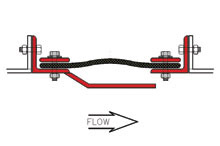

Where is the gasket installed in a fabric expansion joint?

The gasket is a non-porous deformable material that is installed between the belt attachment flange and the fabric belt. The gasket allows a gas-tight seal when the back-up bar clamping action is applied.

What is unique about the style 200W high temperature dirty flue gas expansion joint

It includes integral telescoping liners to retain the accumulation barrier and protect the belt from abrasion.

How is a fabric expansion joint defined?

It is defined as an assembly that utilizes a fabric belt element to allow for the movement of ductwork, as opposed to a metal expansion joint which allows for the movement by means of convoluted metal bellows.

What is the typical operating conditions for high temperature clean air expansion joint applications?

Typical operating conditions are 600 degrees F to 750 degrees F, 5†to 80†WG pressure, clean air media, boiler growth contributes to large axial or lateral expansion joint movements depending on the orientation of the joints.

What kind of frame attachment is commonly used for turbulent flue gas and wet gas expansion joint applications?

Bolt-in design for attachment to equipment or duct flanges. (If equipment or duct flanges are not present, weld in designs are recommended.)

What is design integration for fabric expansion joints?

In addition to fabric expansion joints, U.S. Bellows is a major designer and fabricator of ducting. Design Integration is the design, manufacture, and shipping of expansion joints integrated into the ducting as a complete unit directly from U.S. Bellows. This enables U.S. Bellows to offer optimum system design and the lowest installed cost.

What is angular rotation on a fabric expansion joint?

The twisting of one side of the duct about an axis perpendicular to the longitudinal axis.