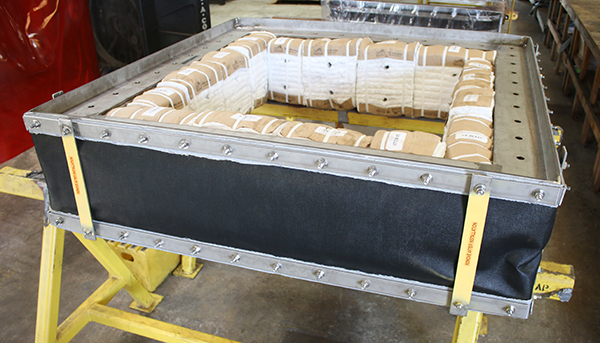

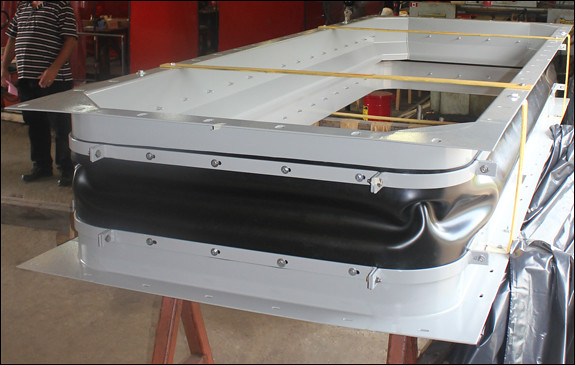

U.S. Bellows, Inc. designed and fabricated this rectangular fabric expansion joint for a heat recovery system at a cement plant in Indiana. The unit was fabricated with a high-temperature PTFE fabric belt and carbon steel frame. The dimensions are 197″ in length, 118″ in width, and 18″ face-to-face. The expansion joint is designed for an operating temperature of -20°-400°F at +/- 60″ water column and 1″ of axial compression and lateral offset. A dye-penetrant exam was performed on all welds before shipment.

Fabric expansion joints are often used in ducts that carry hot gases at low pressures. The major design parameters are the temperatures and flow rates of the gases and the amount and abrasiveness of solids suspended in the gases. Rectangular fabric expansion joints are also used in power plant ducting that requires joints from the boiler or economizer outlet to the chimney.

Also, they can be used on ducting to the coal pulverizers and the furnace-air inlets. Combustion turbines will also use these types of joints in exhaust and heat-recovery ducts. The primary duct movement this type of joint absorbs is axial expansion and contraction due to temperature changes. The expansion joint designer can also design for lateral and angular movements. Elastomers and Plastomers are the basic flexible materials used to construct the belting material for these joints. These sheets can be used in combination with woven glass, metal wire, fluoroelastomers, insulation, and other materials for use in applications where there may be abrasive material, condensate, acids, and other particles that could reduce the expected life of the joint. Our experienced engineers are also skilled in the various methods and fasteners to connect the belting material to the metal frames of the expansion joint.

This expansion joint was designed for a cement plant for one of the largest building material manufacturers worldwide. Such facilities make products ranging from fly ash, slag, masonry, white, specialty and oil well cements for use in commercial construction, residential construction, and industrial applications.

USB REF. ORIGINAL POST 03132017

Read More