U.S. Bellows, Inc. received this 26″ diameter pressure balanced elbow expansion joint for a complete refurbishment. The original condition of the expansion joint can be seen in the top image while the bottom image shows the expansion joint after being refurbished in just under 3 weeks. New SA-240 type 321 stainless steel bellows were used to replace the original bellows, and the tie rods and flow liners were also replaced. All carbon steel parts were painted with a universal primer. This expansion joint measures over 17 feet long center to center of elbows, and is currently being used in an effluent header at Cedar Bayou plant.

Read MoreTag: Elbow Expansion Joints

U.S. Bellows, Inc. received this 26″ diameter pressure balanced elbow expansion joint for a complete refurbishment. The original condition of the expansion joint can be seen in the top image while the bottom image shows the expansion joint after being refurbished in just under 3 weeks. New SA-240 type 321 stainless steel bellows were used to replace the original bellows, and the tie rods and flow liners were also replaced. All carbon steel parts were painted with a universal primer. This expansion joint measures over 17 feet long center to center of elbows, and is currently being used in an effluent header at Cedar Bayou plant.

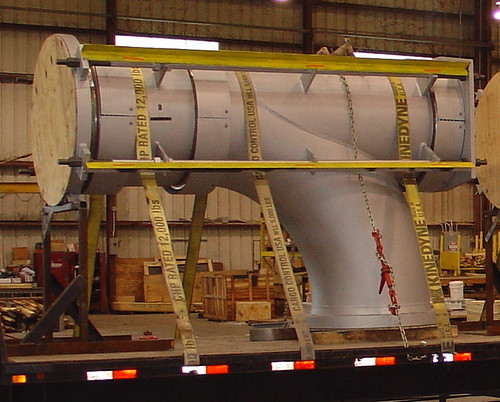

The universal pressure balanced elbow expansion joints were fabricated with 304 stainless steel bellows and carbon steel reinforcing root rings. The expansion joints were designed for an axial compression of .25″, extension of .75″, and lateral of 1″. They have an overall length of 237″ from center line or elbow to face of the weld end. All expansion joints were designed for 100 PSIG and hydro-tested at 150 PSIG.

60″ Diameter Universal Pressure Balanced Elbow Expansion Joints

The universal pressure balanced elbow expansion joints were fabricated with 304 stainless steel bellows and carbon steel reinforcing root rings. The expansion joints were designed for an axial compression of .25″, extension of .75″, and lateral of 1″. They have an overall length of 237″ from center line or elbow to face of the weld end. All expansion joints were designed for 100 PSIG and hydro-tested at 150 PSIG.

Read MoreU.S. Bellows, Inc. designed and fabricated 36″ pressure balanced elbow expansion joints that weigh approximately 4,300 lb. each. The pressure-balanced design does not exert pressure thrust on the equipment in the piping system. The expansion joints are designed with Inconel® 625 grade LCF bellows and include a liner provided with drain holes to prevent the accumulation of corrosive condensation. The design movements are 1/2″ axial compression and 3/4″ lateral movement. The bellows were 100% x-rayed before forming and dye-penetrant examined after forming.

U.S. Bellows, Inc. Designed and Fabricated 36″ Pressure Balanced Elbow Expansion Joints

U.S. Bellows, Inc. designed and fabricated 36″ pressure balanced elbow expansion joints that weigh approximately 4,300 lb. each. The pressure-balanced design does not exert pressure thrust on the equipment in the piping system. The expansion joints are designed with Inconel® 625 grade LCF bellows and include a liner provided with drain holes to prevent the accumulation of corrosive condensation. The design movements are 1/2″ axial compression and 3/4″ lateral movement. The bellows were 100% x-rayed before forming and dye-penetrant examined after forming.

Read More