U.S. Bellows custom-designed and fabricated universal gimbal expansion joints for 24” diameter crude oil pipelines at a power plant in Canada. The bellows are fabricated from A240 316 stainless steel bellows, the flanges are A105N carbon steel, and the plates are A516 70 carbon steel. The expansion joints are designed for a 10 degrees angular rotation at 285 psig up to 100 degrees F. They are designed for an angular spring rate of 4900 in-lb/dec and vertical offset of 10-1/4”. The units measure 43” x 43” x 110” and 38” x 38” x 79”.

3D Modeling was done so that our engineers can check the “fit-up” to confirm the design, perform stress analysis, or other modeling benefits prior to fabrication. We performed hydro tests, completed NDE reports, and supplied Material Test Reports per the client requirements.

U.S. Bellows custom-designed and fabricated universal gimbal expansion joints for 24” diameter crude oil pipelines at a power plant in Canada. The bellows are fabricated from A240 316 stainless steel bellows, the flanges are A105N carbon steel, and the plates are A516 70 carbon steel. The expansion joints are designed for a 10 degrees angular rotation at 285 psig up to 100 degrees F. They are designed for an angular spring rate of 4900 in-lb/dec and vertical offset of 10-1/4”. The units measure 43” x 43” x 110” and 38” x 38” x 79”.

3D Modeling was done so that our engineers can check the “fit-up” to confirm the design, perform stress analysis, or other modeling benefits prior to fabrication. We performed hydro tests, completed NDE reports, and supplied Material Test Reports per the client requirements.

Read More

| Type: |

Universal Expansion Joint |

| Size: |

116″ in diameter/60″ long |

| Material: |

AL6XN Stainless Steel/Carbon Steel |

| Design: |

100°F at 220 psig, 9″ axial compression |

| Testing: |

Dye penetrant, radiographic, and hydro tested |

U.S. Bellows custom designed this 116″ universal expansion joint for a water supply system in California. The unit measures 116″ in diameter and 60″ long. The bellows and pipe spool were fabricated from AL6XN stainless steel and the flanges from carbon steel. It is designed for a temperature of 100°F at 220 psig and 9″ of axial compression. The expansion joint was dye penetrant, radiographic, and hydro tested prior to being shipped out.

| Type: |

Universal Expansion Joint |

| Size: |

116″ in diameter/60″ long |

| Material: |

AL6XN Stainless Steel/Carbon Steel |

| Design: |

100°F at 220 psig, 9″ axial compression |

| Testing: |

Dye penetrant, radiographic, and hydro tested |

U.S. Bellows custom designed this 116″ universal expansion joint for a water supply system in California. The unit measures 116″ in diameter and 60″ long. The bellows and pipe spool were fabricated from AL6XN stainless steel and the flanges from carbon steel. It is designed for a temperature of 100°F at 220 psig and 9″ of axial compression. The expansion joint was dye penetrant, radiographic, and hydro tested prior to being shipped out.

Read More

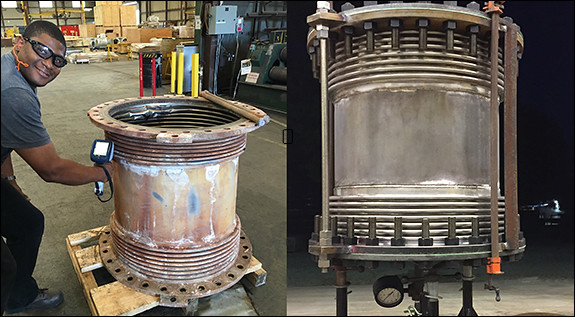

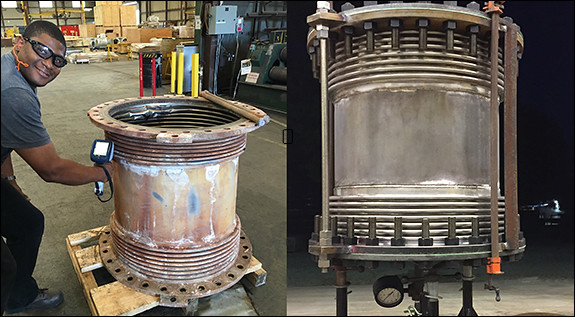

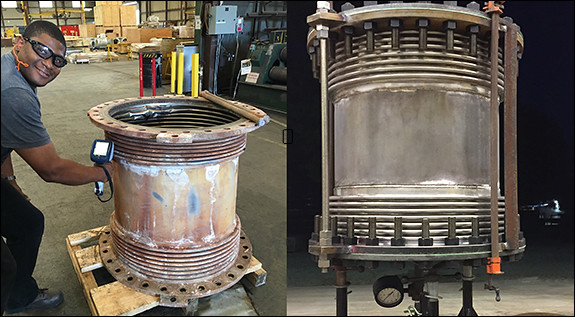

Saturday morning of Memorial Day weekend, the U.S. Bellows team received an emergency request from a large chemical plant who needed to refurbish an expansion joint by replacing both of the bellows. Within 30 minutes, the customer had a response and the project was under way.

U.S. Bellows engineers consulted with the customer and requested the unit be shipped to the facility immediately. After receiving the expansion joint, the team performed a positive material identification (PMI) test. U.S. Bellows assessed the expansion joint and determined the 316 stainless steel bellows could be refurbished. Once the results were concluded, engineering drawings and calculations were finalized.

U.S. Bellows made certain that, despite the Holiday weekend, a skilled team of engineers, fitters, welders and quality control personnel were all involved to ensure the success of the project. The customer service and project success rates are unparalleled because U.S. Bellows has the expertise and the tools we need to get it done right, the first time.

As with any last minute project, there were some unforeseen challenges. However, this didn’t stop the completion of the project, or even slow it down! The 30″ diameter universal expansion joint was refurbished and shipped back to the customer within 24 hours. The unit is back in service at the chemical plant with minimal down time due to the fast-acting U.S. Bellows team.

If you have an emergency request, including field service needs, please call us on our Emergency Hotline at (800) 787-5914 or via our online Emergency Request Form

Saturday morning of Memorial Day weekend, the U.S. Bellows team received an emergency request from a large chemical plant who needed to refurbish an expansion joint by replacing both of the bellows. Within 30 minutes, the customer had a response and the project was under way.

U.S. Bellows engineers consulted with the customer and requested the unit be shipped to the facility immediately. After receiving the expansion joint, the team performed a positive material identification (PMI) test. U.S. Bellows assessed the expansion joint and determined the 316 stainless steel bellows could be refurbished. Once the results were concluded, engineering drawings and calculations were finalized.

U.S. Bellows made certain that, despite the Holiday weekend, a skilled team of engineers, fitters, welders and quality control personnel were all involved to ensure the success of the project. The customer service and project success rates are unparalleled because U.S. Bellows has the expertise and the tools we need to get it done right, the first time.

As with any last minute project, there were some unforeseen challenges. However, this didn’t stop the completion of the project, or even slow it down! The 30″ diameter universal expansion joint was refurbished and shipped back to the customer within 24 hours. The unit is back in service at the chemical plant with minimal down time due to the fast-acting U.S. Bellows team.

If you have an emergency request, including field service needs, please call us on our Emergency Hotline at (800) 787-5914 or via our online Emergency Request Form

Read More

A customer’s existing expansion joint failed and caused a plant to shut down. They required an immediate replacement joint. This universal expansion joint order was placed, designed, and fabricated in just one day. The order came in at 8:30 am on Saturday, Labor Day weekend, and was shipped at 4:00 pm, which minimized the time of the plant shut down. This universal expansion joint is 96″ in overall length, 20″ inside diameter, and can absorb 3.25″ lateral movement. A 100% dye-penetration test and a hydro-test were performed to ensure quality.

|

|

A customer’s existing expansion joint failed and caused a plant to shut down. They required an immediate replacement joint. This universal expansion joint order was placed, designed, and fabricated in just one day. The order came in at 8:30 am on Saturday, Labor Day weekend, and was shipped at 4:00 pm, which minimized the time of the plant shut down. This universal expansion joint is 96″ in overall length, 20″ inside diameter, and can absorb 3.25″ lateral movement. A 100% dye-penetration test and a hydro-test were performed to ensure quality.

Read More