Ensuring Uninterrupted Care: The Critical Role of Expansion Joints in Medical Gas Delivery

In a healthcare facility, the medical gas distribution system is the literal lifeline of the building. At any given time, it could be delivering oxygen to an ICU or maintaining the high-flow vacuum required in a surgical suite, and these systems must operate with zero margin for error.

For hospital facility managers, the challenge isn’t just maintaining the gas supply: it’s protecting the rigid piping network from the invisible forces of thermal expansion, mechanical vibration, and seismic activity. This is where precision-engineered expansion joints become critical safeguards.

Engineering for NFPA 99: Material Standards and Pressure Tolerances

Medical gas systems are unique in their material requirements and pressure sensitivities. To maintain gas purity and system integrity, most hospitals utilize ASTM B819 Level L or K degreased copper tubing.

- Oxygen and Nitrous Oxide Lines: Typically range from 1/2″ to 4″ in diameter, depending on the distance from the bulk source and the number of terminal units served. These lines must remain free of oils and contaminants to prevent spontaneous combustion.

- MRI Equipment: Hospital MRI systems require two kinds of piping systems. Quench Venting systems are safety components in the MRI system. Designed to vent helium gas out of the system during a “quench” event, where the magnet’s cooling system fails and rapidly boils off liquid helium. These lines are 8”-10” NPS Range and made out of stainless steel due to the extreme operating temperature of -270 deg.C.

- Medical Vacuum and WAGD (Waste Anesthetic Gas Disposal): Often use larger diameters, often 6″ to 8″ in main headers, to maintain consistent flow rates without pressure drops.

- Media Types: These systems transport high-purity oxygen (O2), medical air, nitrous oxide (N2O), nitrogen (N2), and carbon dioxide (CO2). Each has specific pressure profiles and temperature sensitivities that exert stress on the piping joints.

Why Rigid Piping Needs Flexible Solutions

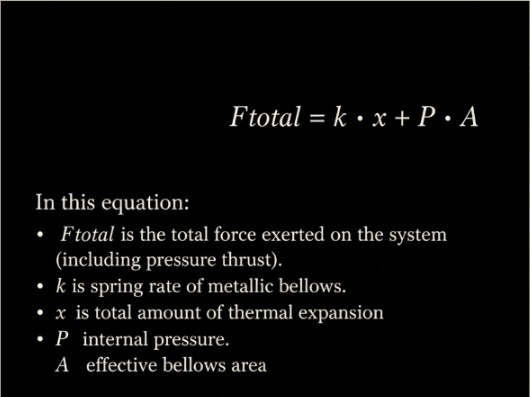

While stainless steel or copper are often the choice for durability in healthcare environments, their thermal expansion coefficient means that long runs of piping will expand and contract as the building’s internal climate or gas temperature fluctuates. Without an expansion joint to absorb this movement, the stress is transferred directly to the brazed joints, leading to hairline fractures and catastrophic leaks.

The NFPA 99 (Health Care Facilities Code) mandates that medical gas systems be protected against physical damage and seismic events. In seismic-prone zones, a rigid pipe can snap during a tremor; a customized metallic expansion joint for seismic activity from US Bellows allows for multi-axial movement, keeping the “lifeline” intact when the building moves.

Selecting the Right Guard: Expansion Joint Types for Healthcare

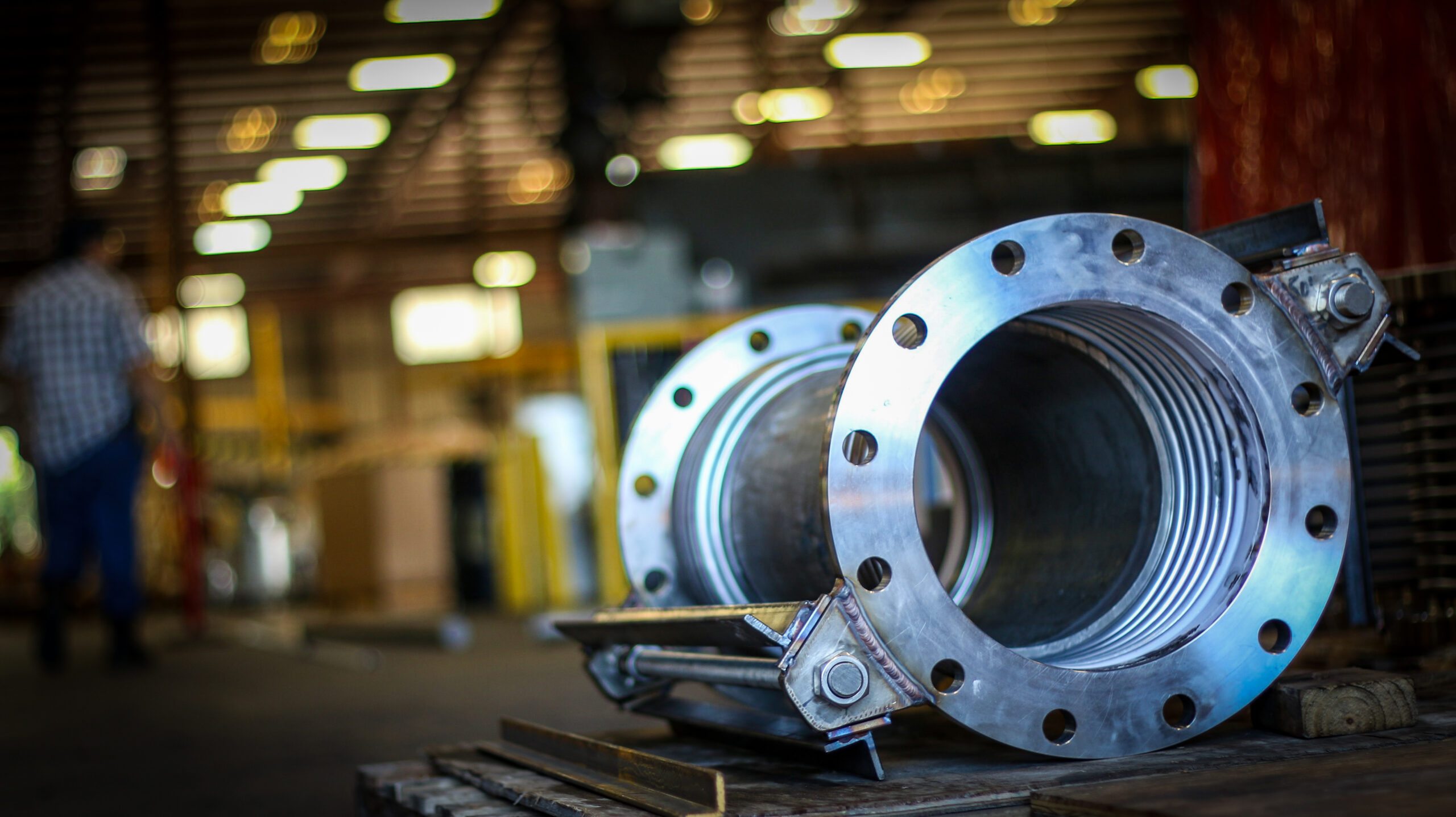

For oxygen, nitrous oxide, and high-pressure steam, metallic expansion joints are the gold standard.

- The Value: They are non-permeable and can be factory-certified as oxygen-cleaned.

- Application: Ideal for sterilization lines where temperatures often reach 121 °C to 134 °C

Hospitals are “Category 1” structures, meaning they must remain functional during and after an earthquake. Universal Gimbal expansion joints use a specialized “ring” harness to allow for angular rotation in any plane.

- The Value: They absorb multi-axial movement while resisting pressure thrust, eliminating the need for massive, costly concrete anchors in tight ceiling cavities.

- Application: Critical for main headers crossing building expansion joints, to absorb a substantial amount of lateral movement

A hospital’s HVAC system is its lungs. Fabric expansion joints are used in low-pressure air handling units (AHUs).

- The Value: They act as vibration breakers, preventing mechanical hum and fan noise from traveling through the ductwork into patient recovery zones.

- Application: Large-diameter air intake and exhaust systems.

Hospital Medical Piping: Expansion Joint Selection & Pressure Rating Guide

|

Application

|

Recommended Type

|

Primary Value

|

| Medical Gas / O2 |

Metallic |

Gas purity & high burst pressure (1,000 psi) |

| MRI Pipelines |

Metallic |

Chilled water & Helium venting/quenching |

| Seismic Protection |

Universal Gimbal |

Multi-axial movement & anchor load reduction |

| HVAC / Air Ducting |

Fabric |

Noise reduction & vibration dampening |

| Sterilization Steam |

Metallic |

Thermal expansion at 121 °C to 134 °C |

The US Bellows Value: Engineering for Zero-Failure Environments

At US Bellows, we understand that hospital infrastructure demands more customization. Our expansion joints for medical gas service are:

- Oxygen-Cleaned: Every joint is factory-cleaned and certified for oxygen service, ensuring no hydrocarbons or oils enter your high-purity lines.

- Compliance-First: We design in accordance with EJMA standards and facilitate compliance with NFPA 99 requirements for metallic flexible connectors.

- Material Integrity: We utilize high-grade stainless steel bellows and bronze or copper end fittings to match the metallurgy of your existing system, preventing galvanic corrosion.

FAQ: Expansion Joints in Healthcare Facilities

What are the NFPA 99 requirements for flexible connectors in medical gas systems?

NFPA 99 requires that flexible connectors be used only where necessary for expansion or vibration control, and that they have a minimum burst pressure of 1,000 psi. They must be made of materials like stainless steel, bronze, or copper that are compatible with the gas being served.

Can rubber expansion joints be used for medical oxygen lines?

Generally, no. For high-purity medical gases, metal bellows (typically stainless steel) are preferred because they are non-permeable and can be easily degreased and cleaned for oxygen service, whereas certain elastomers may degrade or pose a fire risk in high-oxygen environments.

How do expansion joints help with hospital MRI and imaging equipment?

Expansion joints act as vibration isolators. By installing them on the HVAC and chilled water lines serving imaging suites, you prevent mechanical vibrations from the plant room from reaching sensitive diagnostic equipment, which could otherwise cause “noise” in imaging results.

What is the typical lifespan of a metal expansion joint in a hospital setting?

When properly engineered and installed, a high-quality metal expansion joint can last 20 years or more. However, regular inspections every 3–5 years are recommended to detect signs of fatigue or corrosion, especially in steam-intensive environments such as sterilization centers.

Why are chiller water lines in imaging suites typically constructed from non-ferrous materials like copper or stainless steel?

Precision medical imaging equipment, such as MRI machines, relies on powerful and highly sensitive magnetic fields. To ensure the accuracy of these diagnostics, the surrounding infrastructure must not create magnetic interference.

We use non-ferrous metals (typically in the 2” NPS range) for chiller water piping because they are non-magnetic. Using stainless steel or copper prevents the piping from “tugging” on or distorting the machine’s magnetic field. Because these metals have different thermal expansion rates than standard carbon steel, integrating precision expansion joints is critical to absorb thermal movement without risking leaks or mechanical stress near the sensitive equipment.

Secure Your Hospital’s Infrastructure Today

Don’t wait for a “Code Red” leak to evaluate your system’s flexibility. If you are upgrading an existing wing or designing a new surgical center, our engineers can provide a custom assessment of your medical gas piping needs.

Contact a US Bellows engineer for a consultation on your next project.

Read More

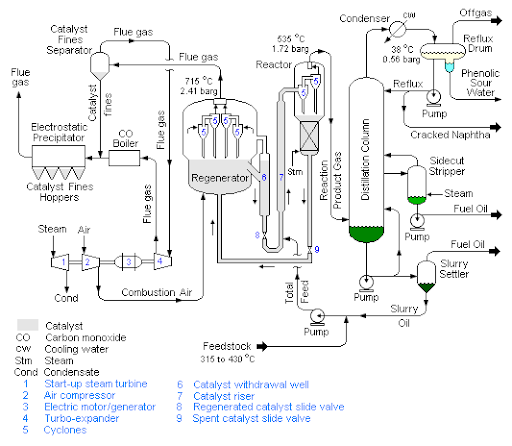

Refinery piping is a dynamic system. In an FCCU, the transition from ambient temperature to whole operation can cause a 100-foot-long pipe to expand by nearly 12 inches. If rigid connections constrain this movement, the resulting stress will concentrate at the weakest point—typically a weld or a critical component of rotating equipment.

Refinery piping is a dynamic system. In an FCCU, the transition from ambient temperature to whole operation can cause a 100-foot-long pipe to expand by nearly 12 inches. If rigid connections constrain this movement, the resulting stress will concentrate at the weakest point—typically a weld or a critical component of rotating equipment.