A careful inspection of the entire piping system shall be made with particular emphasis on the following.

-

Are the anchors, guides and supports installed in accordance with the system drawings?

-

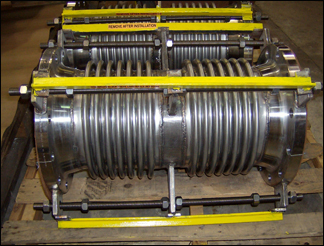

Is the proper pipe expansion joint in the proper location?

-

Are the pipe expansion joint flow direction and positioning correct?

-

Have all the pipe expansion joint shipping devices been removed?

-

Are all guides, pipe supports and the pipe expansion joints free to permit pipe movement?

-

If the system has been designed for a gas, and is to be tested with water, have provisions been made for proper support of the additional dead weight load on the piping and pipe expansion joint? Some water may remain in the bellows convolutions after the test. If this is detrimental to the bellows or system operation, means shall be provided to remove such water.

-

Has any pipe expansion joint been damaged during handling and installation?

-

Is any pipe expansion joint misaligned? This can be determined by measuring the pipe expansion joints’ overall length, inspection of the convolution geometry, and checking clearances at critical points on the pipe expansion joint and at other points in the system.

-

Are the bellows and other movable portions of the pipe expansion joint free of foreign material?