Why Your Industrial Piping Needs Metal Expansion Joints

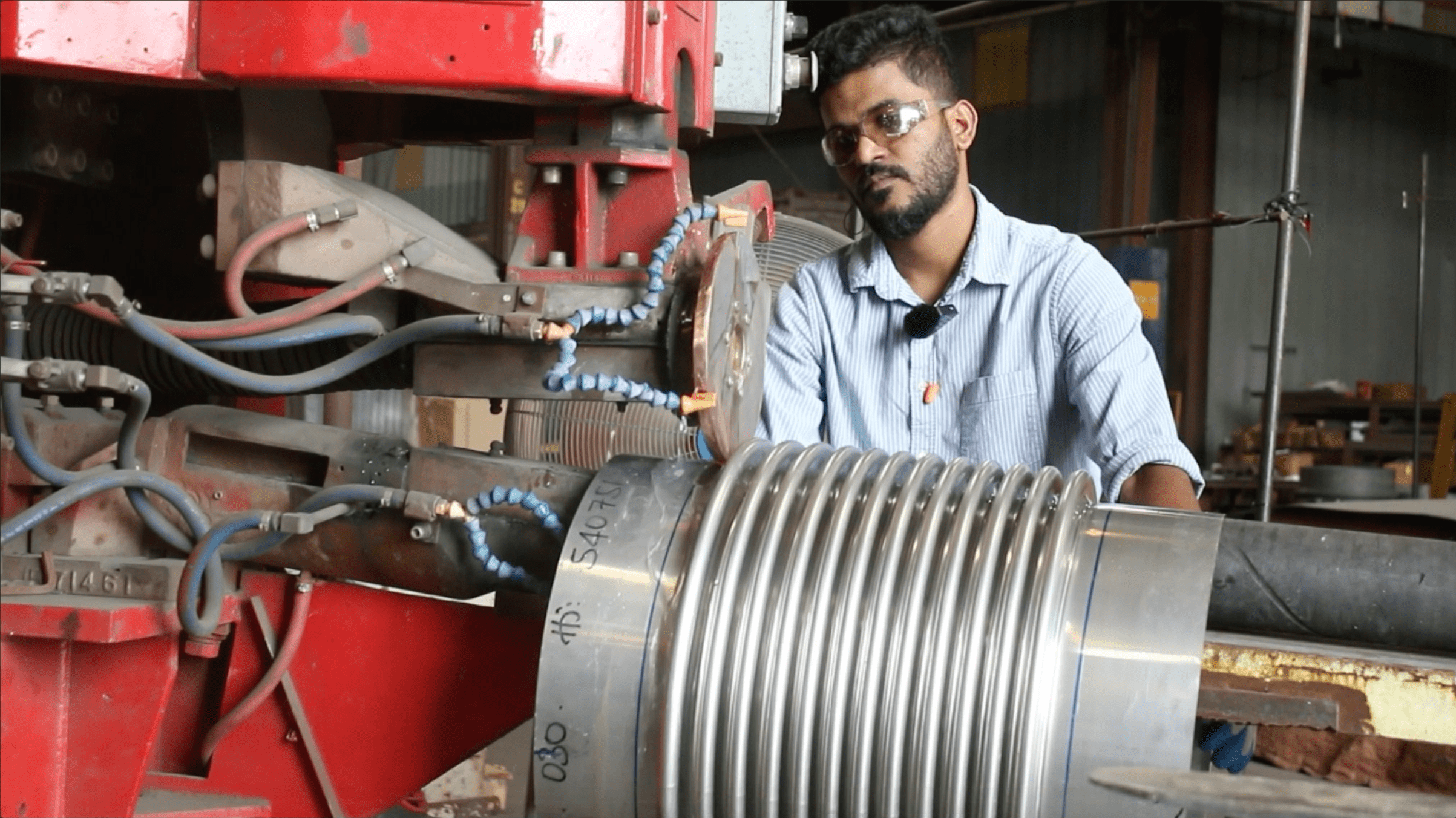

Metal expansion joints are indispensable components in industrial piping and duct systems, serving as flexible connectors designed to absorb movement. Often overlooked until a problem arises, these specialized components are crucial for ensuring the safety and lifespan of complex piping infrastructure. They manage the stresses and movements induced by thermal changes, equipment vibration, seismic activity, and misalignments, and their inclusion is a critical factor in pipe stress analysis (PSA), often providing the most economical solution for keeping pipe reaction loads within acceptable limits for connected equipment and supports.

5 Critical Reasons Metal Expansion Joints are Essential

Here are the top five reasons why metal expansion joints are fundamental to industrial piping systems:

1. Absorbing Thermal Movement and Expansion

Industrial processes often involve significant temperature changes, causing pipes to expand and contract. This thermal movement creates immense stress on the entire piping system, anchor points, and/or equipment. Metal expansion joints, particularly the bellows section, are engineered to compress, extend, shift sideways, and angulate, effectively absorbing the thermal movement. Without them, the cumulative stress could lead to pipe warping, cracking, or failure at welds, anchors, and equipment.

2. Maintaining Intended Alignment to Avoid Unexpected Strain

During installation or due to foundation settling, pipes may not align perfectly. Expansion joints can accommodate minor axial, lateral, or angular misalignment, reducing installation time and preventing “built-in” stresses that compromise the system from day one.

It is essential to address misalignment during the design phase, rather than making adjustments in the field. Using an expansion joint to compensate for large field misalignment can shorten its lifespan.

3. Protecting Equipment by Reducing Vibration & Loads

Piping systems are often connected to vibrating equipment like pumps, compressors, and turbines. If this vibration is transmitted directly through the pipes, it can cause noise, fatigue, and damage to the surrounding structure and equipment. Expansion joints can act as dampers, isolating vibration and preventing its propagation, thus extending the operational life of the machinery and the piping. Note: Expansion joints cannot absorb all types of vibrations, and in some cases, other custom solutions may be more effective.

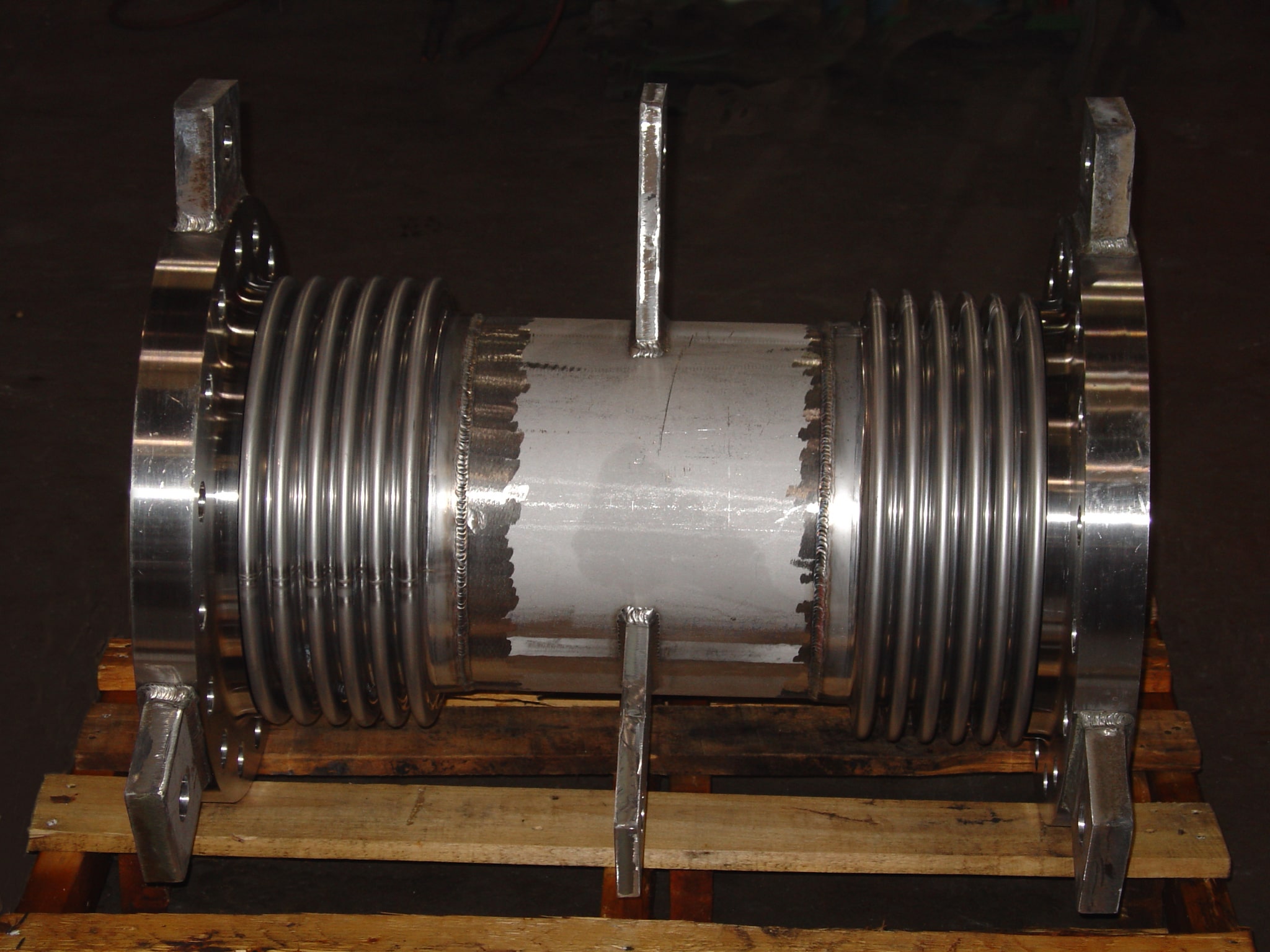

4. Absorbing Pressure Thrust and Movement

Internal pressure in a pipe exerts a thrust force on the system. When a pipe changes direction and using an anchor is not feasible or cost-effective, the pressure force created by the line must still be contained. Specialized, tied or hinged metal expansion joints are designed to withstand this pressure thrust, protecting sensitive equipment and anchors from overstress while still allowing lateral or angular displacement.

5. Enhancing System Safety and Reliability

By managing movement, vibration, and pressure thrust, expansion joints significantly reduce the risk of catastrophic pipe failure, leaks, and downtime. They are a proactive safety measure that contributes to a more reliable and maintainable operation. Investing in high-quality metal expansion joints improves the overall safety and continuous operation of your facility.

Partner with the Experts at US Bellows: Protect Your Piping Infrastructure

US Bellows: Engineered for Extreme Performance. We design and manufacture custom-engineered metal expansion joints that solve your toughest thermal, pressure, and vibration challenges, helping you ensure maximum uptime and safety in your critical industrial applications.

Don’t wait for a failure to start thinking about movement control. Book a meeting with our US Bellows engineering team today to discuss custom expansion joint solutions.