Pressure Balanced Expansion Joints in Piping Design

The design of a piping system is crucial in industrial settings, where failure can result in damage and downtime. One of the biggest challenges engineers face is managing the immense thrust forces generated by pipeline pressure. These forces can strain anchors, damage equipment, and compromise the entire system. This is where the innovative design of pressure-balanced expansion joints (elbow and in-line) adds value, offering a scalable solution to a complex problem.

What Are Pressure Balanced Expansion Joints?

Pressure-balanced expansion joints are highly engineered components designed to absorb thermal pipe expansion and contraction, as well as lateral movements, while simultaneously neutralizing the pressure thrust force that would otherwise act on surrounding anchors, supports, and equipment.

The Mechanism of Balance

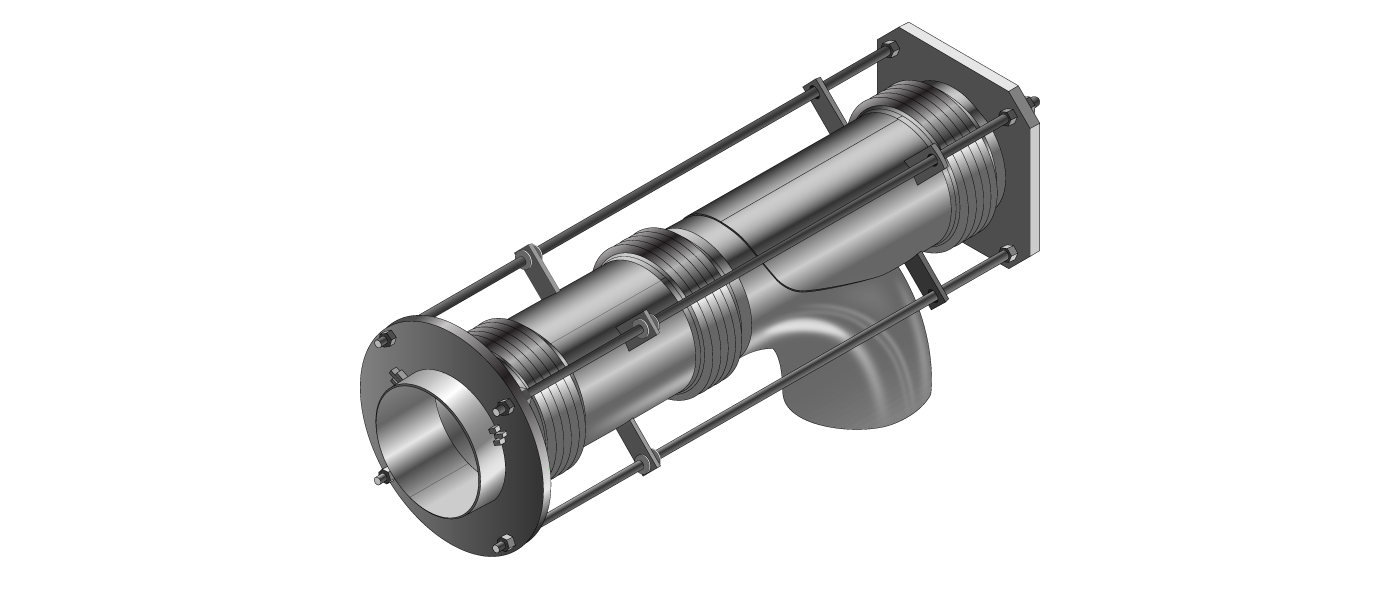

The value lies in their unique internal mechanism. This is accomplished by using a balancing bellows that is exposed to the same pressure as the main, or inline bellows. For in-line pressure-balanced expansion joints, the balancing bellows is specifically designed with an effective area twice that of the inline bellows. For elbow pressure-balanced expansion joints, the effective area remains the same for all bellows.

The core principle is simple but powerful: the pressure acts on both bellows, but the force generated by the balancing bellows acts in the exact opposite direction of the force generated by the inline bellows. Since the entire expansion joint is tied via tie-rods, this creates a state of force equilibrium, effectively containing the thrust from the pressure within the expansion joint.

The thermal movement absorption of the in-line pressure-balanced expansion joints follows that same principle. The inline bellows will compress, while the balancing bellows will actually extend by the same amount as the thermal compression. See our Inline pressure balance EJ below in action:

This neutralization eliminates the need for large, expensive main anchors, as the only forces the anchors must now contend with are the minor spring forces required to move the bellows themselves. This makes them ideal for systems with limited space, poor structural support, for protecting fragile components, or systems where it’d be impractical or cost-effective to install anchors.

When to Use Pressure Balanced Expansion Joints

These specialized joints are instrumental in situations where the system cannot handle the pressure thrust forces, such as:

- Piping connected to sensitive equipment: They protect pumps, turbines, and compressors from axial forces that could cause damage.

- Systems with limited structural anchoring: In crowded plants or offshore applications where large anchors are not feasible, these joints offer a compact, effective solution. Also, in situations where the piping is elevated, it would not be cost-effective to install an elevated anchor.

- Where Low Loadings Are Needed: In specific applications, especially on large-diameter lines or when connecting to thin-walled equipment, minimizing all loads on the surrounding structure is a primary design driver.

Precision-Engineered Trust: Choose US Bellows

US Bellows is an industry-leading manufacturer of high-quality expansion joints, committed to precision engineering and reliability.

When you specify a US Bellows pressure-balanced expansion joint, you are investing in certainty and safety. Our expansion joints are custom-engineered solutions designed by experts to solve your specific piping challenges. We offer:

- Custom Design & Sizing: Every joint is engineered to the precise size, pressure, temperature, and movement requirements of your application, ensuring perfect force neutralization and decades of reliable service.

- Unmatched Material Quality: We utilize advanced materials and stringent welding processes, including specialized alloys for high-temperature and corrosive environments, guaranteeing optimal performance and longevity.

- Code Compliance & Certification: Our manufacturing adheres to strict industry codes, including ASME Section VIII, Div. 1, and B31.3, ensuring fully certified, safe, and dependable products.

- On-site Field Services: We inspect your bellows for loss of pressure, signs of leakage, and observe for specific movement due to pressure.

Stop designing systems around enormous anchors and start protecting your critical equipment with the precision of our solutions at US Bellows.

Ready to reduce pipe stress? Contact US Bellows today to discuss your elbow pressure-balanced expansion joint needs.